Connecting structure of assembly type composite floor slab and cast-in-place beam

A technology of superimposed floor slabs and cast-in-place beams, applied to floors, truss structures, building structures, etc., can solve the problems of difficult installation and collision of reserved anchoring steel bars, and achieve reliable mechanical performance, collision avoidance, and rapid hoisting In place effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

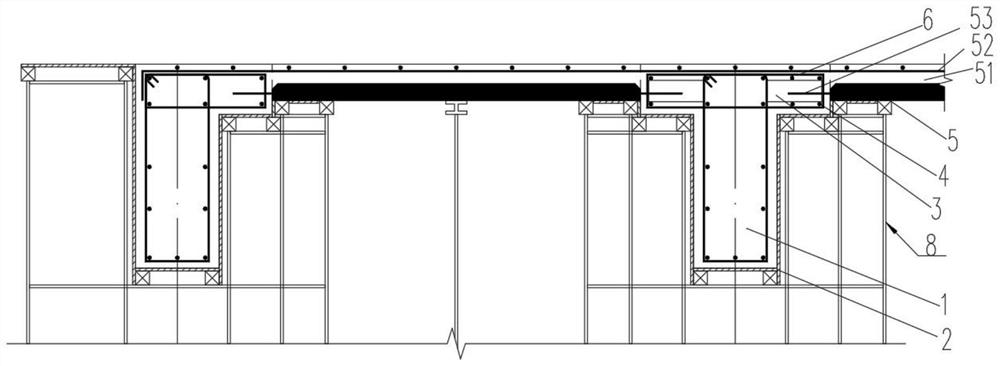

[0014] figure 1 It is a schematic diagram of the overall structure of the present invention; as shown in the figure, a connection structure between an assembled composite floor and cast-in-place beams includes a cast-in-place beam 1 installed in a cast-in-place beam template 2 and a cast-in-place beam 1 connected Laminated floor slab 5; two sides of the cast-in-place beam 1 extend outward to form pick ears 3, and ring-shaped stirrups 6 for use with the laminated floor slab 5 are installed on the pick ears 3. The connection structure of the technical solution , which can realize the rapid hoisting of the laminated floor in place at the construction site, avoiding the collision between the reserved anchoring steel bars of the laminated floor and the cast-in-place beams, and solving the problem that the reserved anchoring steel bars of the laminated floor are not easy to install. With the setting of ring-shaped stirrups, there is no need to cut corners at the beam-column joints w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com