Modularized enclosure cage structure and construction method

A modularized and caged technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as poor safety guarantee, low rigidity, and short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

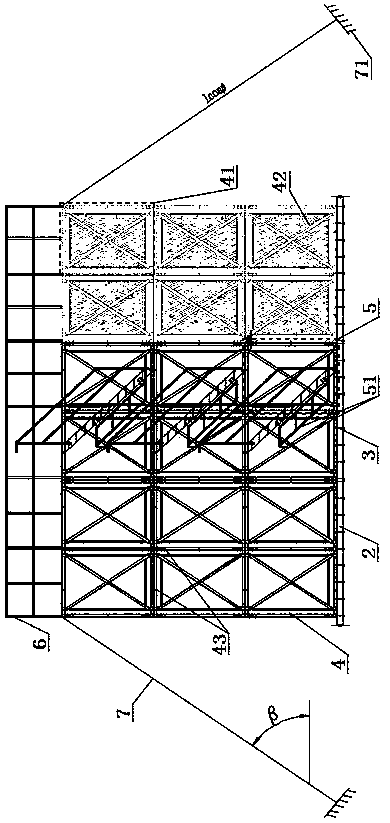

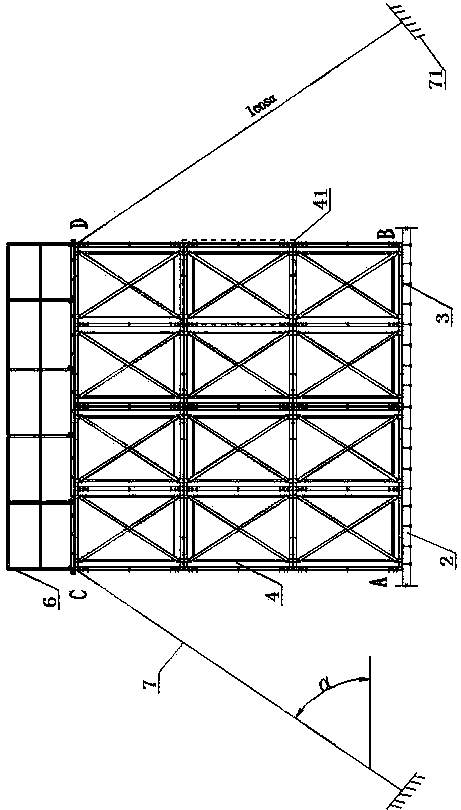

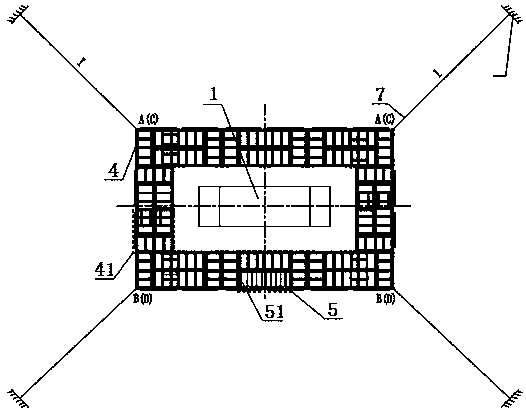

[0073] Such as Figure 1~Figure 4 As shown, 1. Bridge pier, 2. Concrete foundation, 3. Anchor bolts, 4. Cage structure, 41. Cage unit, 42. Protective cover, 43. Connecting bolts, 5. Ladder unit, 51. Ladder, 6. Railing, 7. Cable wind, 71. Ground anchor.

[0074] Modular pier cage structure and construction methods, such as figure 1 , figure 2 As shown, it involves a combination of multiple modular cage units 41 and multiple ladder units 5 arranged on the concrete foundation, and enclosed around the pier 1 to form a closed bridge pier cage 4 structure.

[0075] The cage unit 41 is a steel square frame structure, which is assembled from a variety of steel members, and a mesh protective cover is welded on the outside of the frame structure, and bolt holes are reserved on the bottom, top and surroundings of the frame structure , the middle of the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com