Suspension type crane equipment and its learning device

一种学习装置、设备的技术,应用在运输和包装、输送机、载荷吊挂元件等方向,能够解决被夹持部制作精度低、精度误差、伸长量误差等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

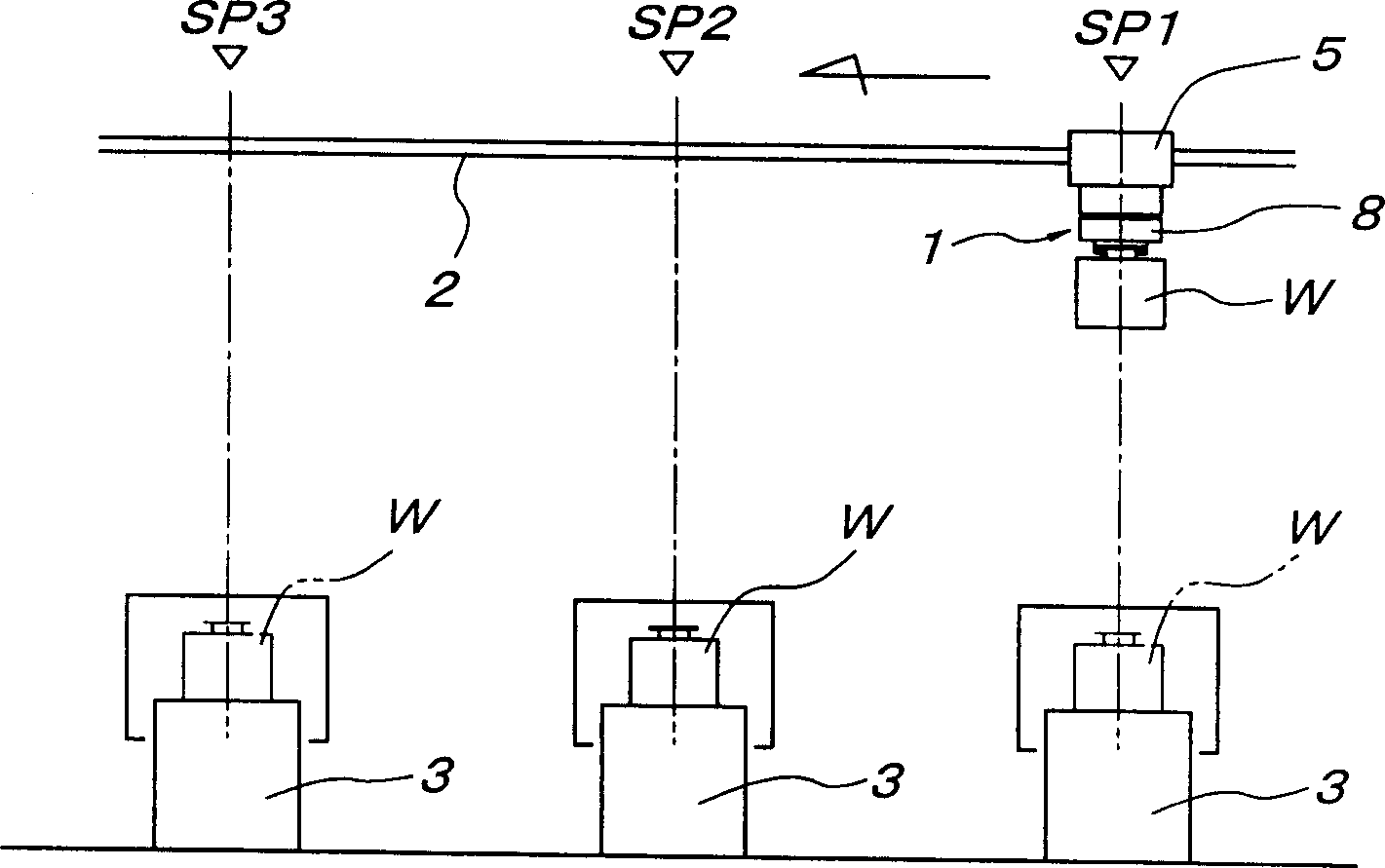

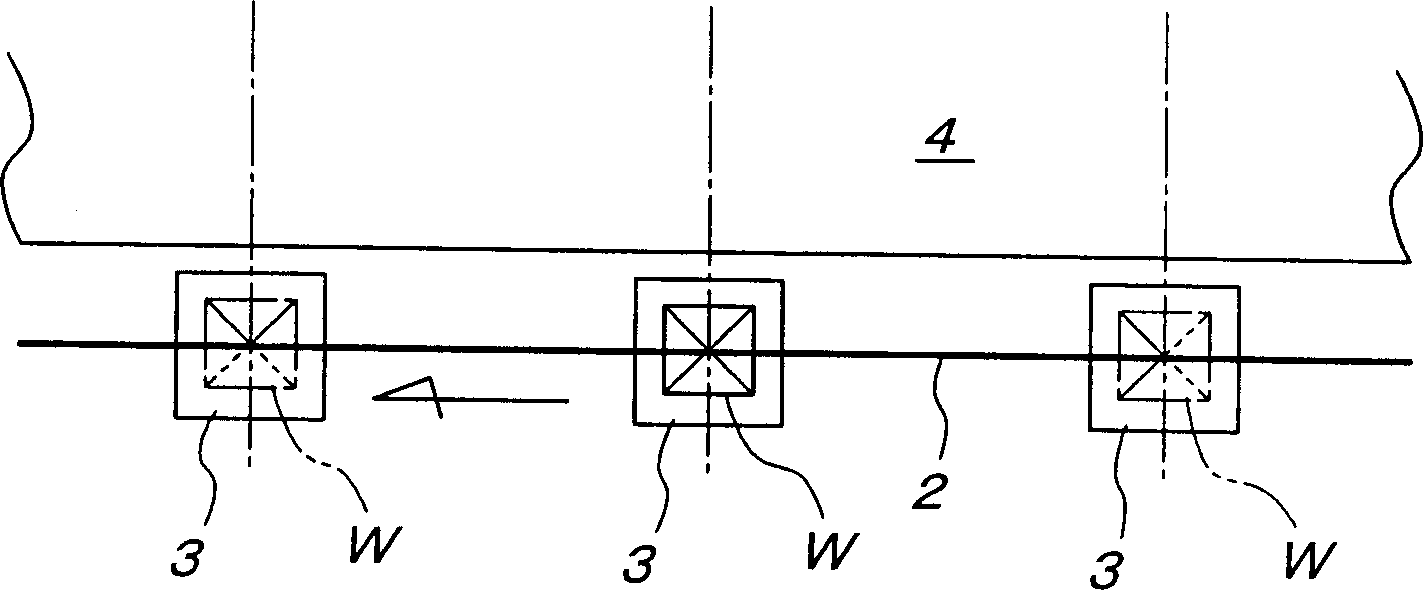

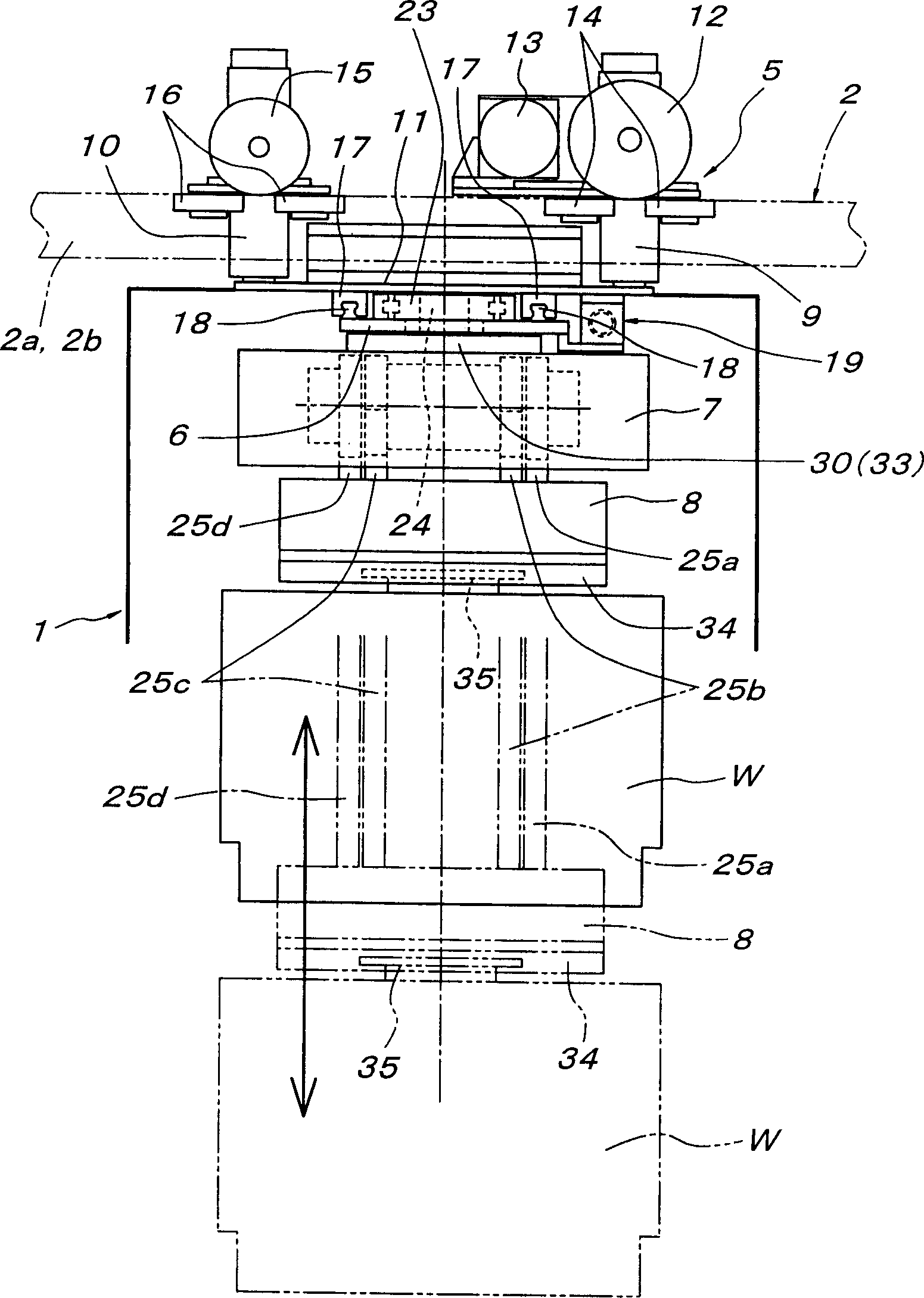

[0040] Below according to accompanying drawing, preferred embodiment of the present invention is described, and in Fig. 1, label 1 represents suspension conveyance device, and it is to be supported on the guide rail 2 of the appropriate height that erects on the top plate side, and self along this guide rail 2 Carry out the trolley form of walking, under the walking path of this suspension transport device 1 (on the ground below the guide rail 2), with appropriate spacing, be provided with workpiece transfer with supporting platform (hereinafter referred to as loading port for short) 3. Each loading port 3 is formed in such a way that it is arranged adjacent to the workpiece handling equipment 4, and the unprocessed workpiece W dropped from the above-mentioned suspension transport device 1 to the specified loading port 3 passes through the automatic transfer mechanism. , into the inside of the workpiece processing equipment 4, through the automatic transfer mechanism, the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com