Screwing-in anchoring device for crane

A technology for anchoring devices and cranes, which is applied in the directions of safety devices, transportation and packaging, and load hanging components, etc. Reliable, compact structure, scientific and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

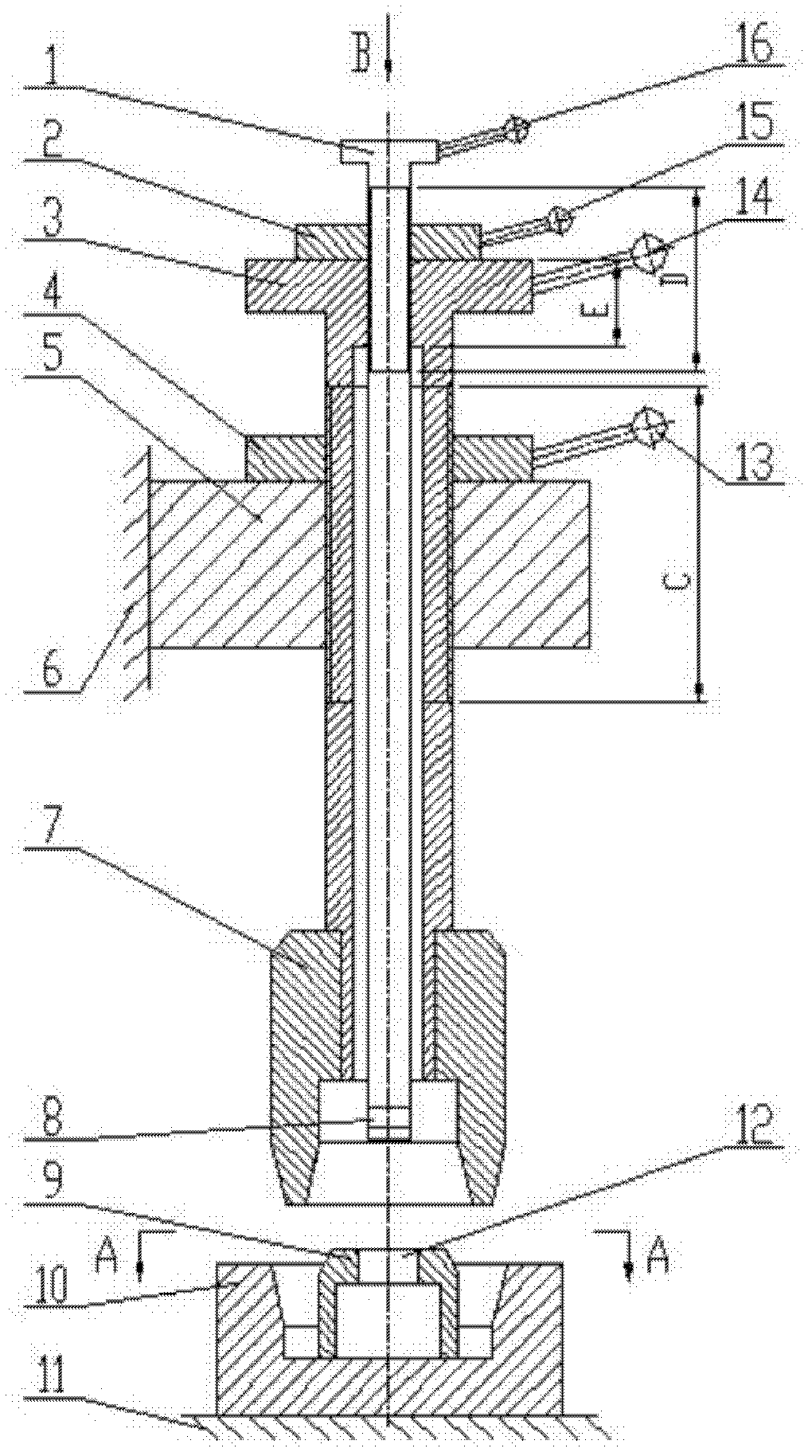

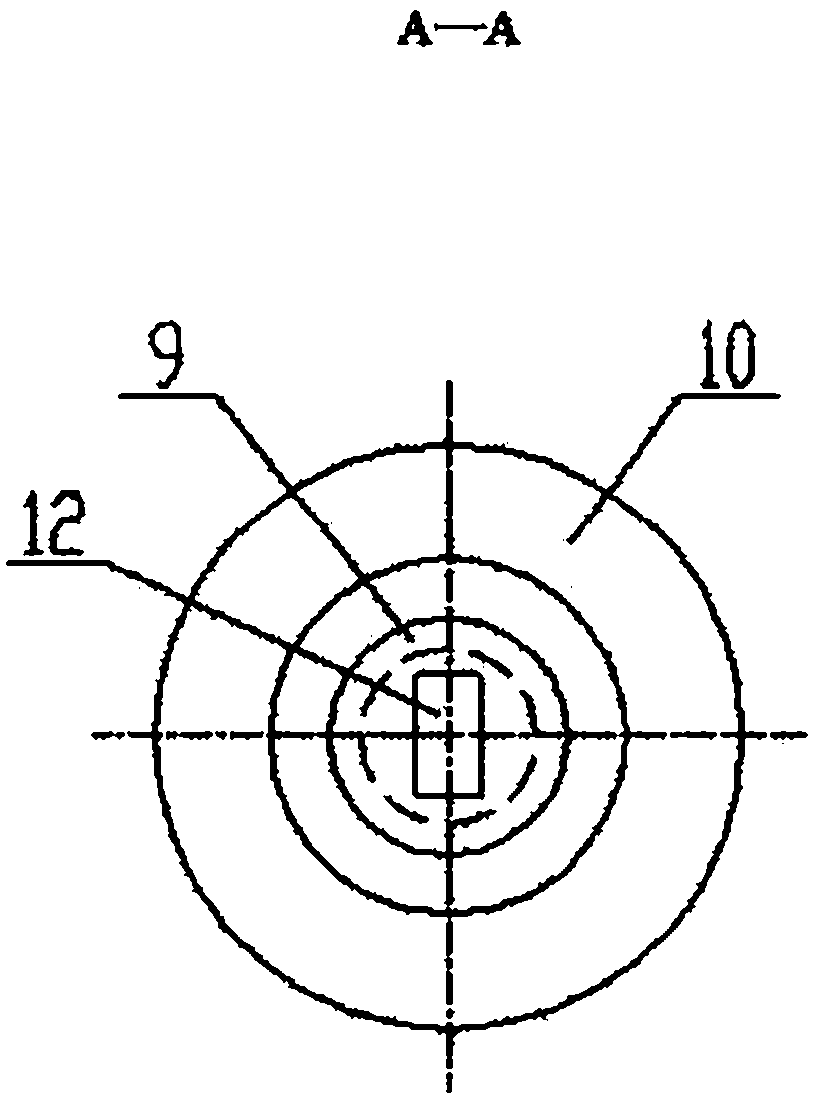

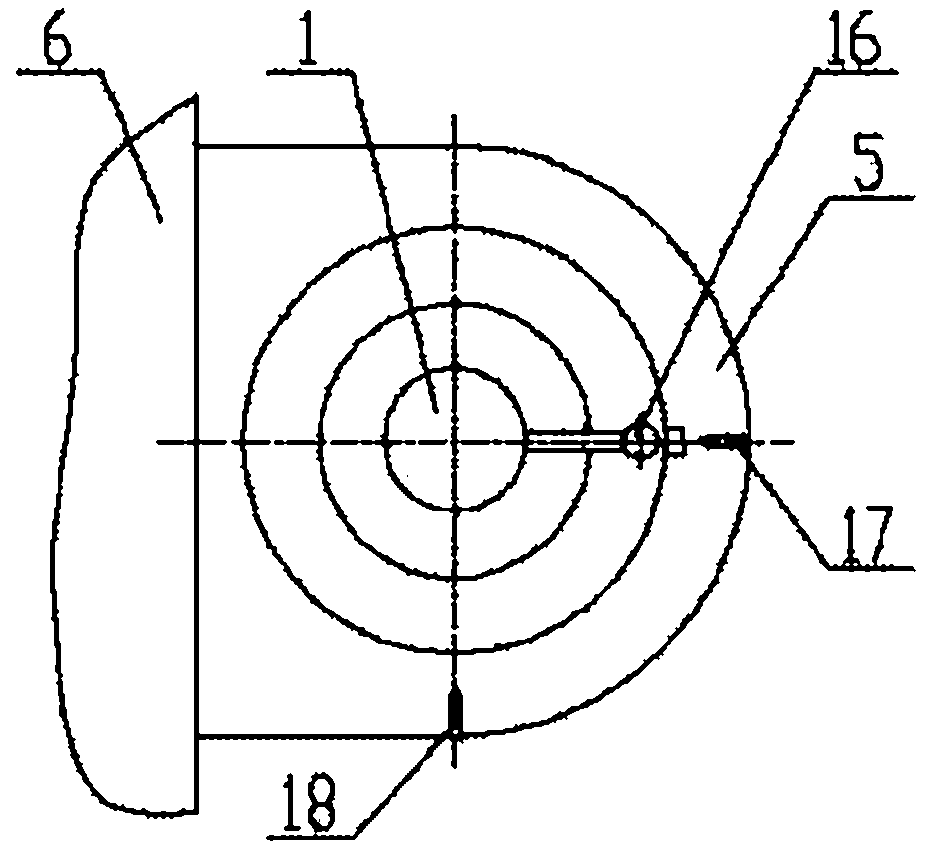

[0017] figure 1 , 2 Shown is a specific embodiment of the present invention; it is a crane screw-in type anchoring device installed on a nuclear power fuel crane; it is characterized in that: a screw-in type anchoring device is installed on the trolley frame 6 of the crane, the described The anchoring device consists of support plate 5, A mark 17, B mark 18, hollow screw 3, guide cone head 7, inner screw 1, small nut 2, large nut 4, square locking block 8, locking sleeve 9 and guide cone 10 components, the support plate 5 is connected on the side of the trolley frame 6, and the top surface of the support plate 5 is respectively equipped with A mark 17 and B mark 18 with an angular distance of 90°, and the support plate 5 is threaded Connect the hollow screw 3, the two ends of the hollow screw 3 are exposed outside the support plate 5, the bottom end of the hollow screw 3 is connected to the guide cone 7, and the top of the hollow screw 3 is a flange head, in this method The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com