Installation method for high-altitude large-span steel trusses

An installation method and steel truss technology, which are applied in the processing of building materials, construction, building construction, etc., can solve the problems of high installation height, limited crane arm length, and large span, and achieve low cost, good economic benefits, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with specific embodiments.

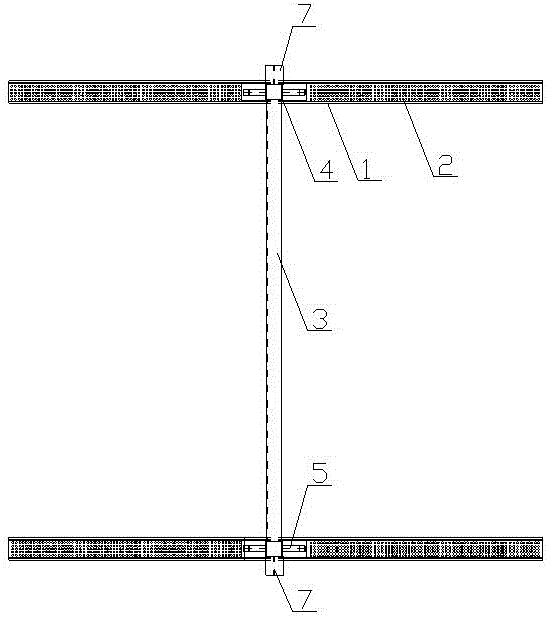

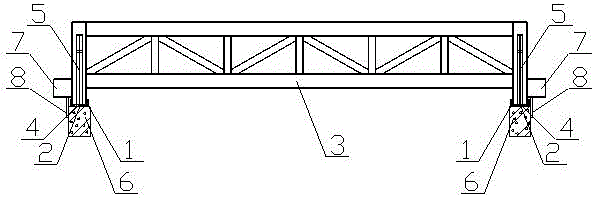

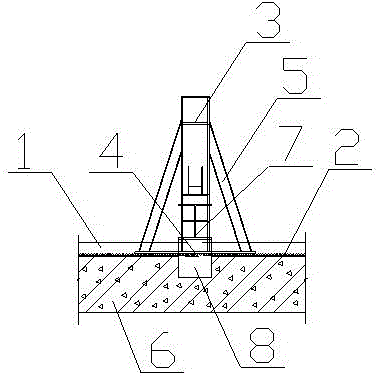

[0032] Such as Figure 1-3 As shown, a method for installing high-altitude large-span steel trusses is characterized in that the trusses are lifted to the required vertical height outside the building, and then the trusses are slid in place by the air sliding method, installed and fixed, and pulled up. cable wind rope; specifically include the following steps:

[0033] 1) Set up a rail 1 with a "concave" cross section at the installation place of the support 4 embedded parts at both ends of the large-span steel truss 3, and make the two rails 1 with a "concave" cross section parallel to each other. The two parallel tracks can make the two ends of the large-span steel truss 3 slide in the track without deviation or overturning.

[0034] 2) Apply lubricant and sprinkle spherical steel marbles 2 on the track 1 with a "concave" cross section to provide sufficient lu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com