Sliding-type roof draught fan system and installation method thereof

A sliding type, fan technology, applied in the field of building steel structure, can solve the problems of water leakage around the roof fan opening, achieve long-term waterproof effect, avoid stress concentration, and avoid high-altitude welding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical means of the present invention and the technical effects that can be achieved more clearly and more perfectly disclosed, the following embodiments are provided hereby, and the following detailed descriptions are made in conjunction with the accompanying drawings:

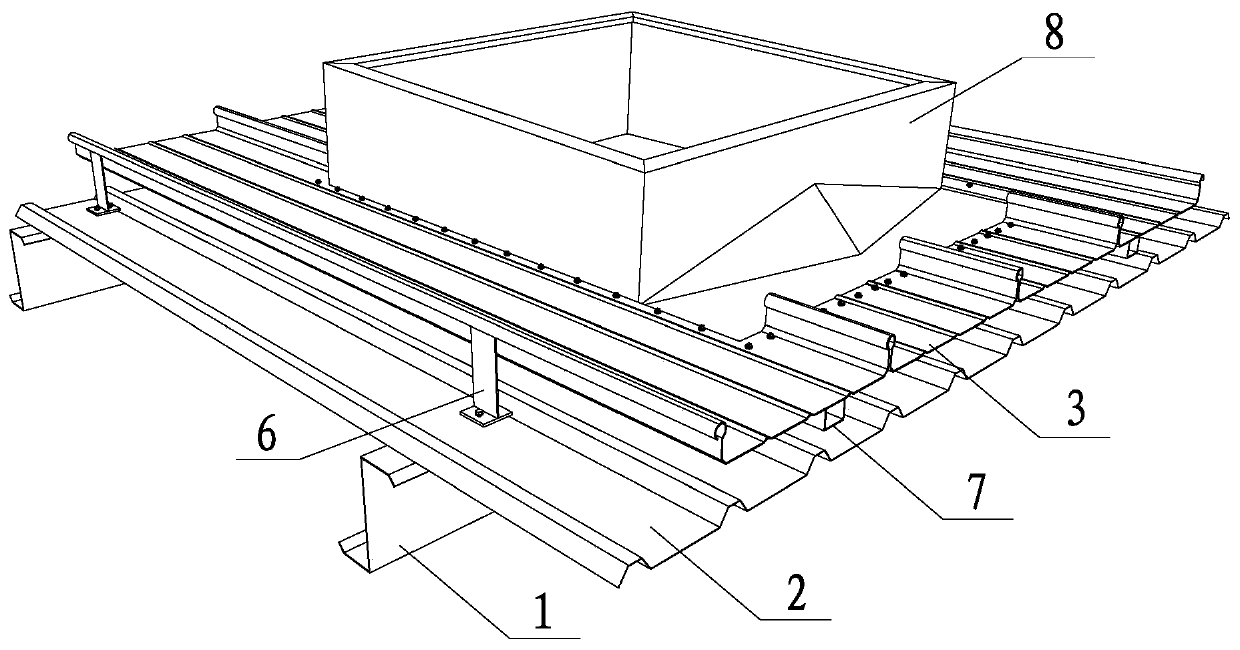

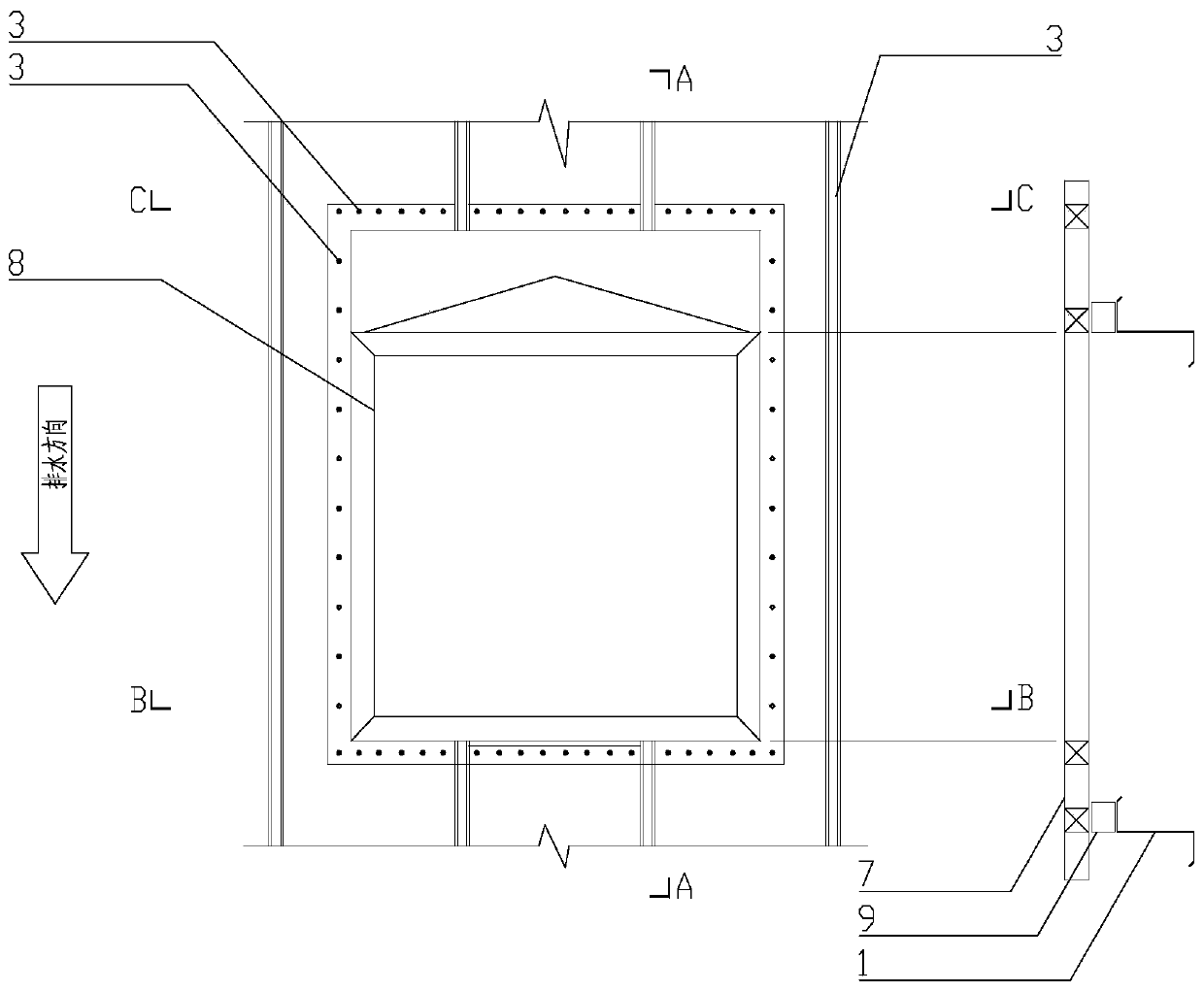

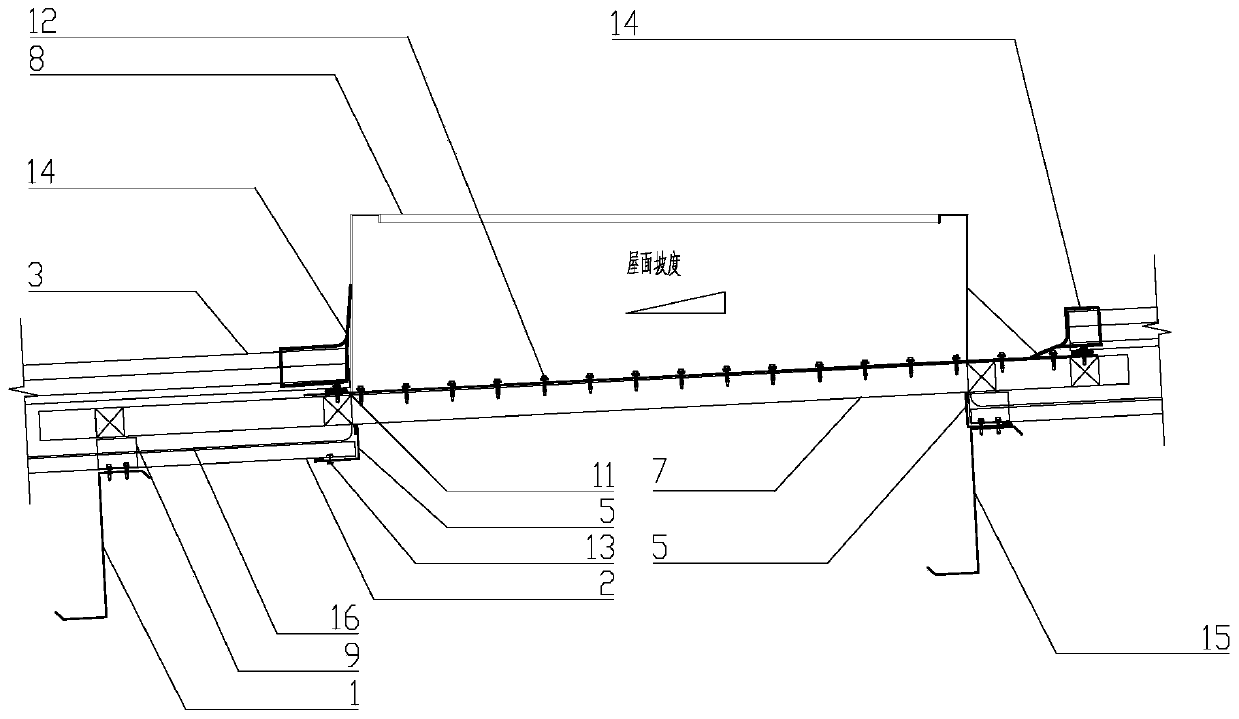

[0042] Such as Figure 1 to Figure 16 As shown, a sliding roof fan system in this embodiment includes roof purlins 1, a roof base plate 2 fixed on the roof purlins 1, and a fan opening 4 set on the roof base plate 2, including 4 fan openings. The fan bracket 7 fixed on the roof base plate 2 but not fixed with the roof base plate 2, the fan base 8 fixed on the fan bracket 7, the sliding support 6 fixed on the roof base plate 2 and located around the fan hole 4, and the Move the upper roof panel 3 of the sliding support 6; the upper roof panel 3 is provided with a hole and is fixed with the surrounding edges of the fan base 8, and the joint between the upper roof panel 3 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com