A kind of installation method of fpso ship seawater riser assembly stage

A seawater lifting and installation method technology, applied in the direction of ships, etc., can solve the problems of thin structure, lack of structural support, difficult installation of seawater pipes, etc., to achieve the effect of saving costs and prolonging the period of the dock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

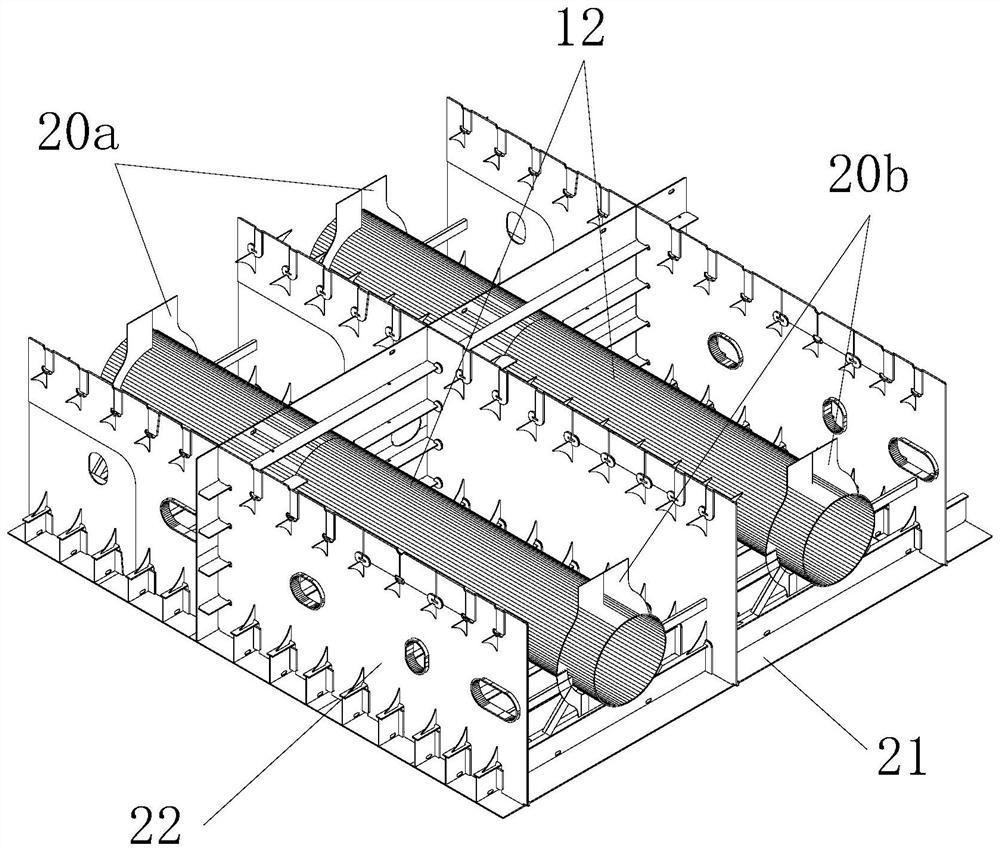

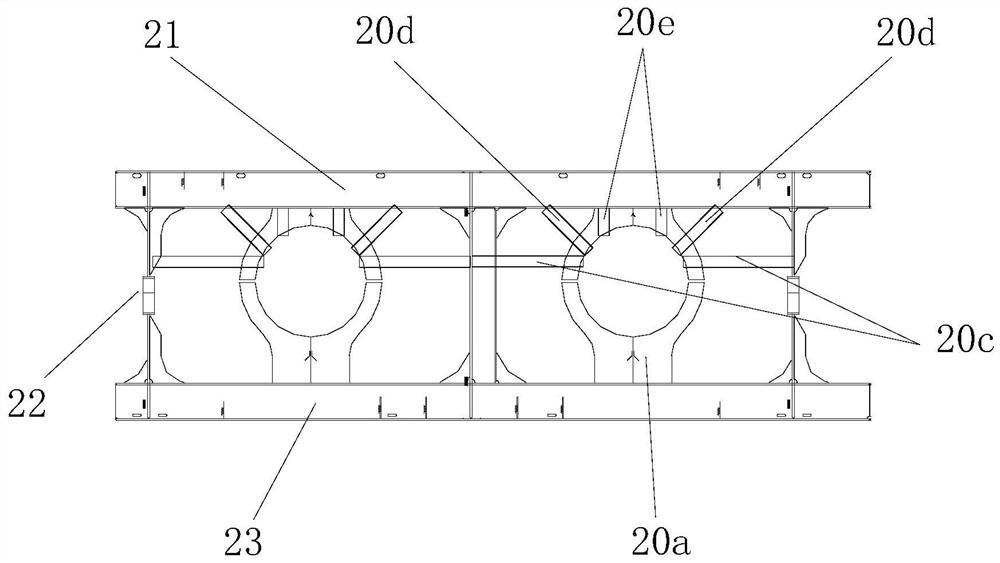

[0029] The present invention will be further described below in conjunction with accompanying drawing.

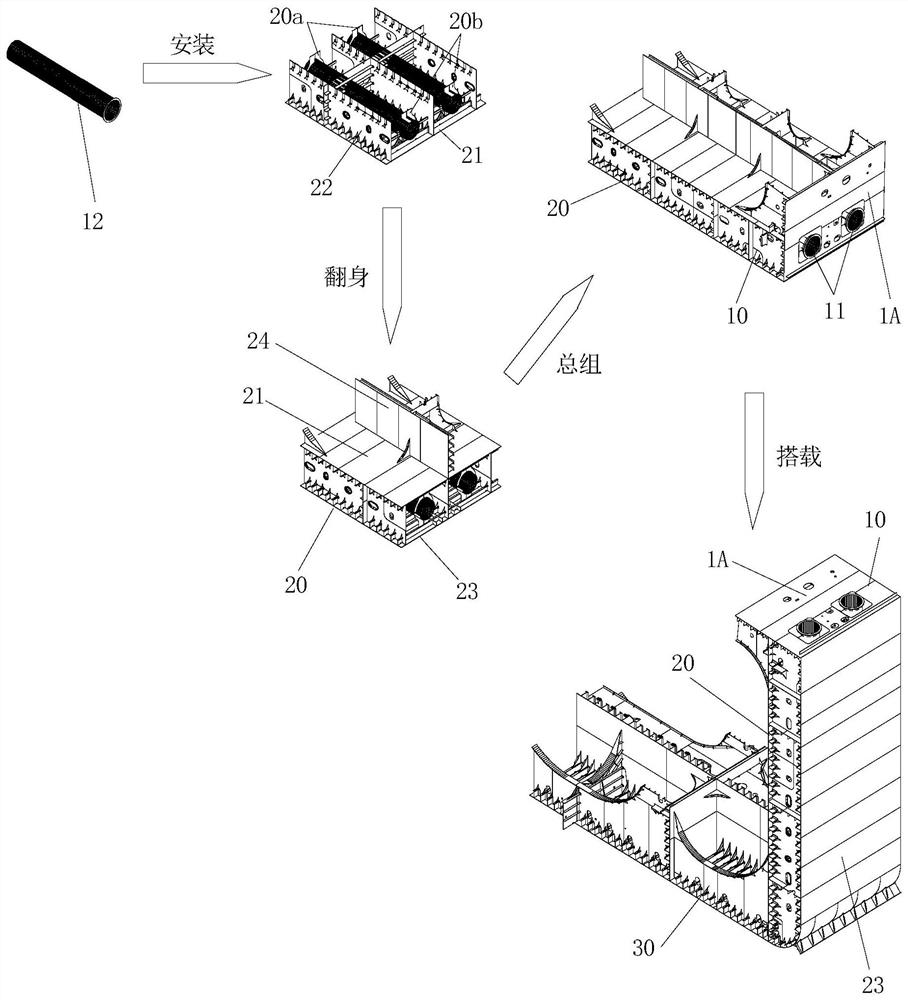

[0030] see first Figure 1 to Figure 3 , the installation method of the seawater riser assembly stage of the FPSO ship of the present invention, the seawater riser involved is composed of a top-down pipe jacking section 11, a main pipe section 12, a base section and a steel casting, the pipe jacking section 11, the main pipe section 12 and the base section are installed on the 67 subsections 10, 63 subsections 20 and 27 subsections 30 between the FR58 ribs and FR62 ribs on the starboard side of the hull in one-to-one correspondence.

[0031] The installation method of the FPSO ship seawater riser assembly stage of the present invention includes 67 segmental large assembly, 63 segmental large assembly, 27 segmental large assembly, general assembly and loading;

[0032] Performing the 67-segment large group immediately includes the following steps:

[0033] Step 1: install ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com