Roof floor type support and construction method thereof

A construction method and floor-standing technology, which can be applied to pillars, protective buildings/shelters, earthquakes, etc., can solve problems such as difficulty in ensuring the installation quality of pre-embedded supports, and achieve the effect of avoiding high-altitude welding and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

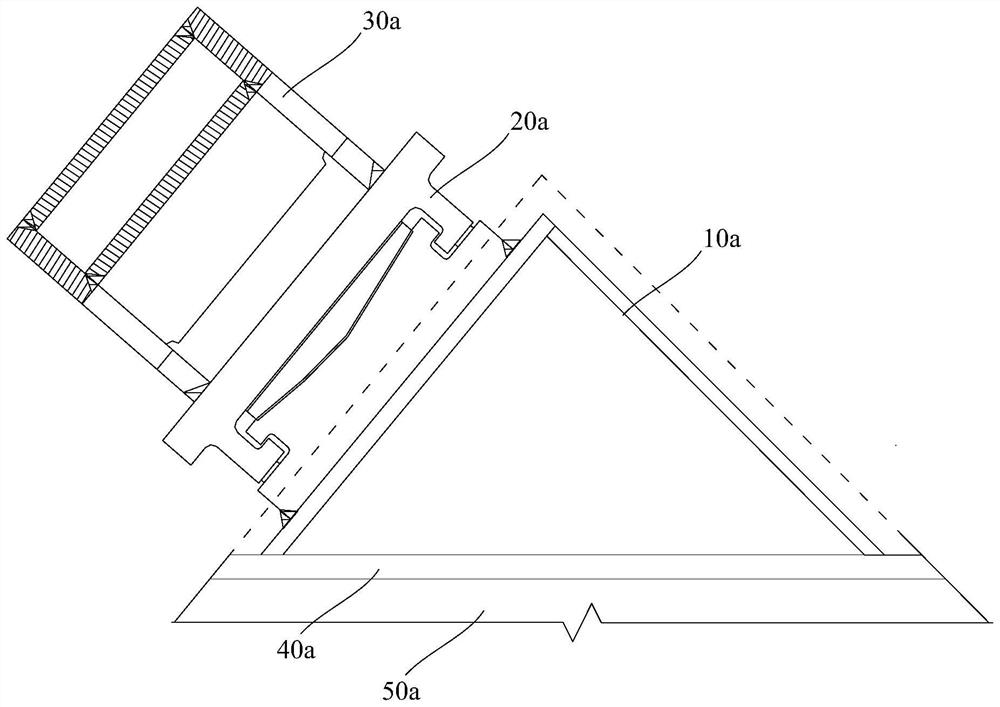

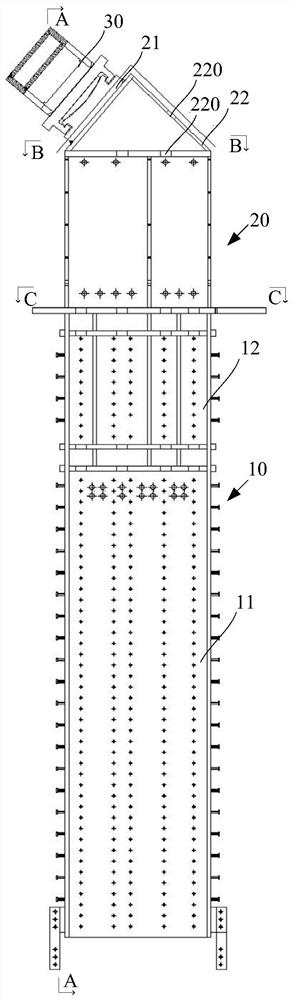

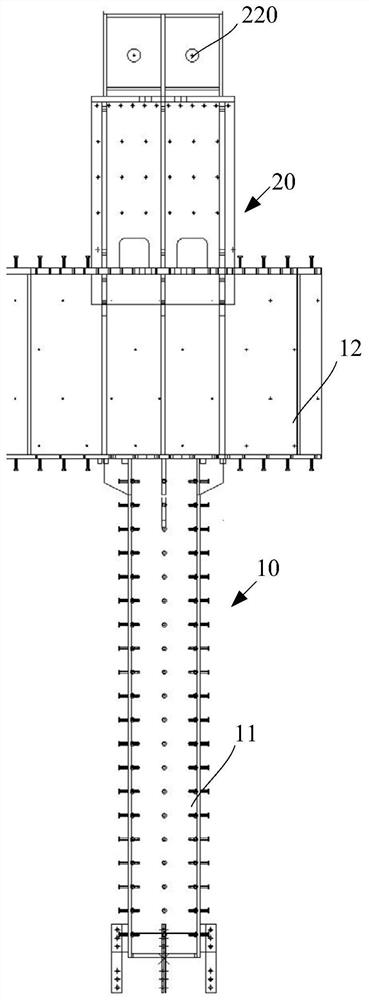

[0051] refer to figure 2 , shows a front view of an embodiment of the roof floor stand of the present invention. image 3 for figure 2 Schematic diagram of the A-A direction. Figure 4 for figure 2 Schematic diagram of the B-B direction. Figure 5 for figure 2 Schematic diagram of the C-C direction. to combine Figure 2 to Figure 5 As shown, the roof floor support of the present invention includes:

[0052] erecting beam-column framework 10 fixed on the ground;

[0053] The square platform framework 20 integrally fixed on the top of the beam-column framework 10, the top of the square platform framework 20 forms an obliquely arranged mounting plate 21;

[0054] Concrete poured on the beam-column skeleton 10 and the square platform skeleton 20 to form a skeleton concrete structure; and

[0055] The anti-seismic structure 30 installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com