A three-machine hoisting installation and construction method for a bow-shaped space truss

A technology of space truss and construction method, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of difficult guarantee of welding quality, influence on project progress, and long construction period, so as to achieve easy implementation of construction methods and improve welding The effect that quality, construction methods are simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

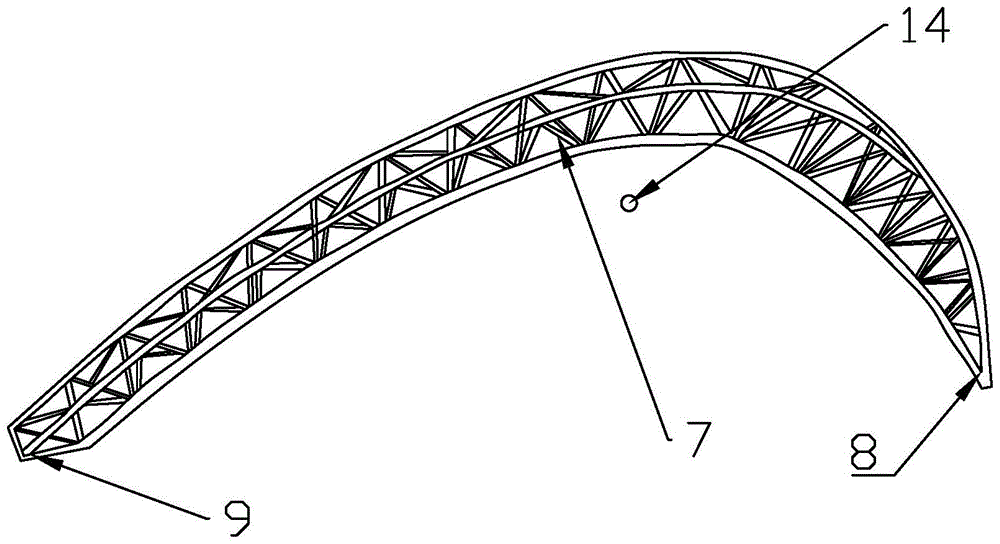

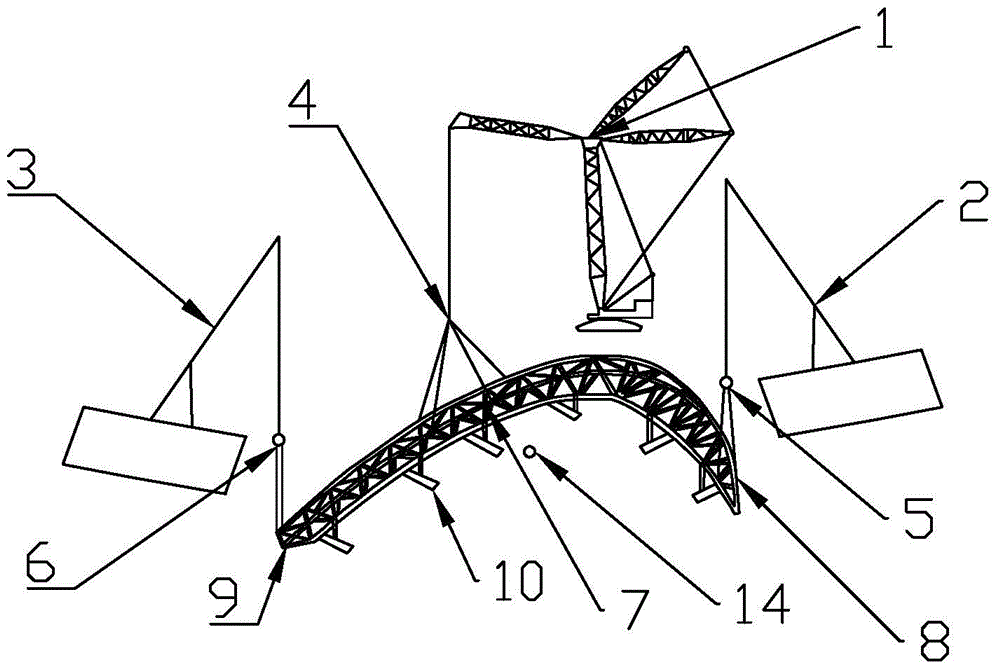

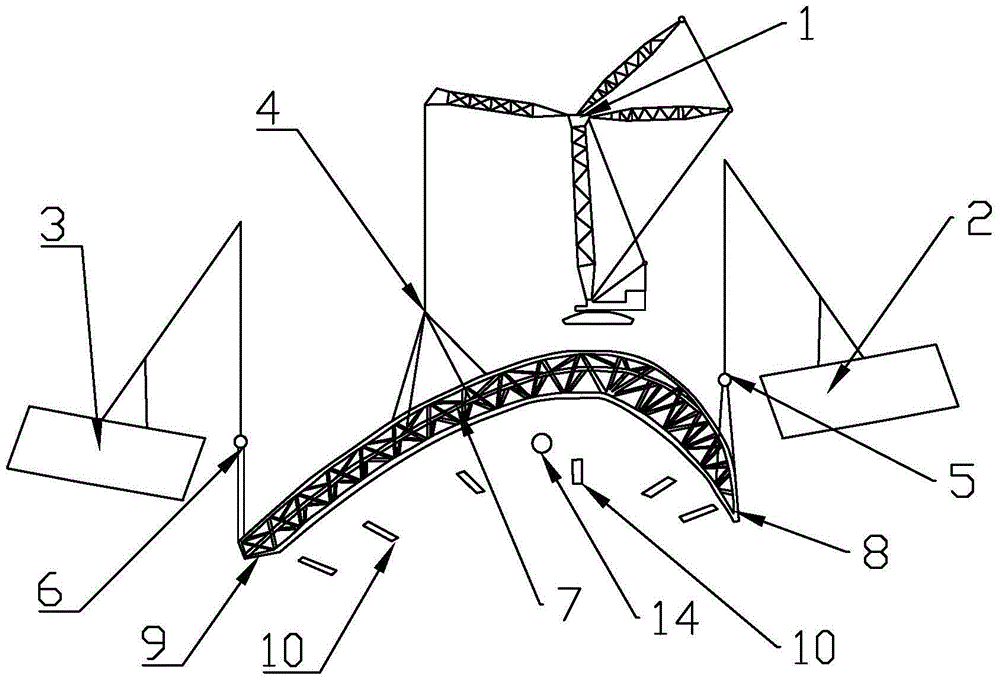

[0028] Such as Figure 1 to Figure 5 As shown, the construction process of a bow-shaped space truss hoisted by three cranes is as follows: simulation to determine the center of gravity of the bow-shaped space truss → setting three lifting points and three cranes → using three cranes to carry out bodiless work → waiting After the bodiless work is completed, carry out the straightening work → hoist the bow-shaped space truss on the platform 11 → fix the bow-shaped space truss on the platform 11 .

[0029] (1) Simulation to determine the center of gravity of the bow-shaped space truss: first establish the space entity model of the bow-shaped space truss, and then determine whether the bow-shaped space truss is in the horizontal, turning, straightening, and hoisting positions according to the shape and size of the bow-shaped space truss Center of gravity position on platform 11. Since the position of the center of gravity of the bow-shaped space truss will continue to change with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com