Rotary symmetric plug pin insertion mechanism and horizontal-type tension test machine

A rotational symmetry and plug-in technology, applied in the direction of applying stable tension/pressure to test the strength of materials, hand-held tools, measuring devices, etc., can solve problems such as laboriousness, low efficiency, and inability to plug and unplug, so as to save labor and hoisting costs , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in the preferred embodiment are only for convenience of description, and are not used to limit the scope of the present invention. The scope of implementation and the change or adjustment of its relative relationship shall also be regarded as the scope of implementation of the present invention without substantive changes in technical content.

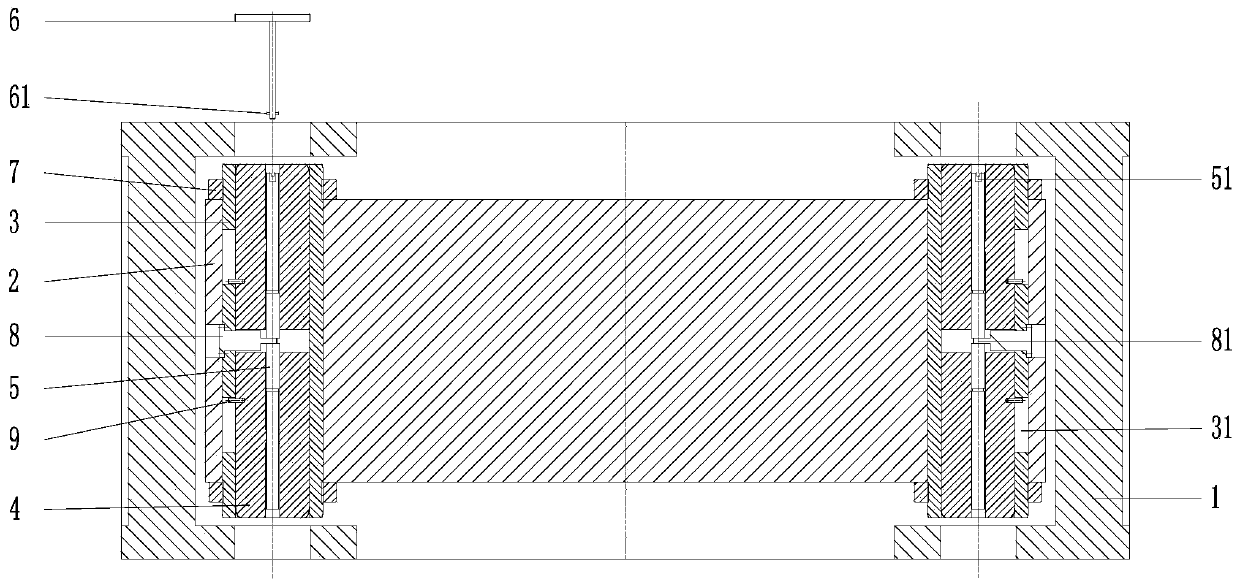

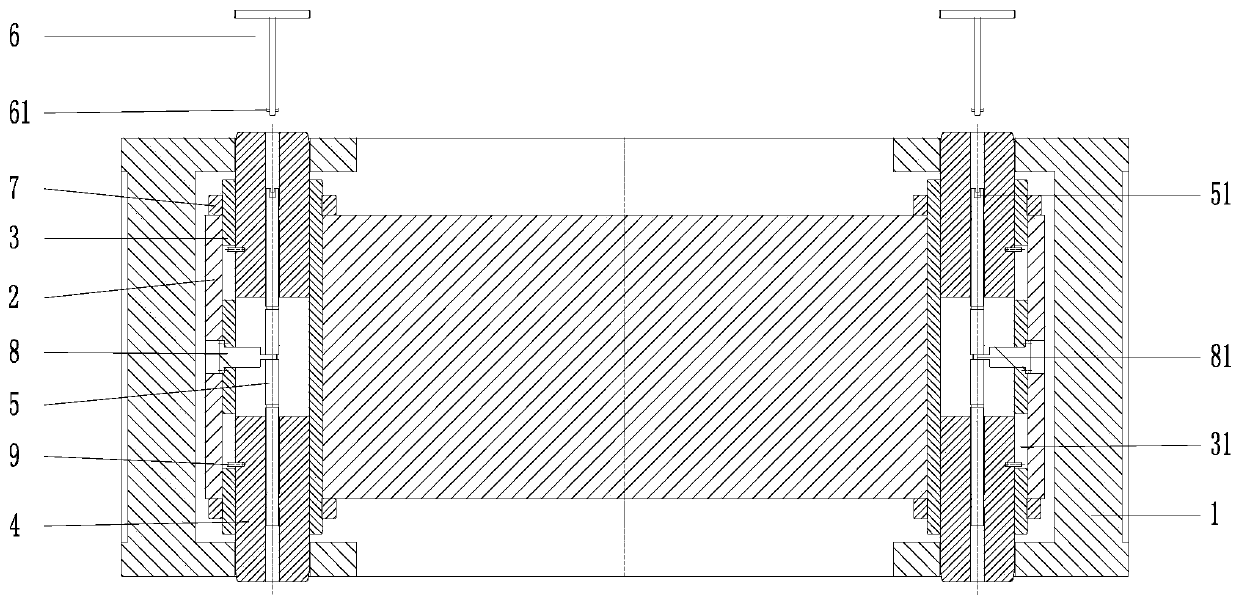

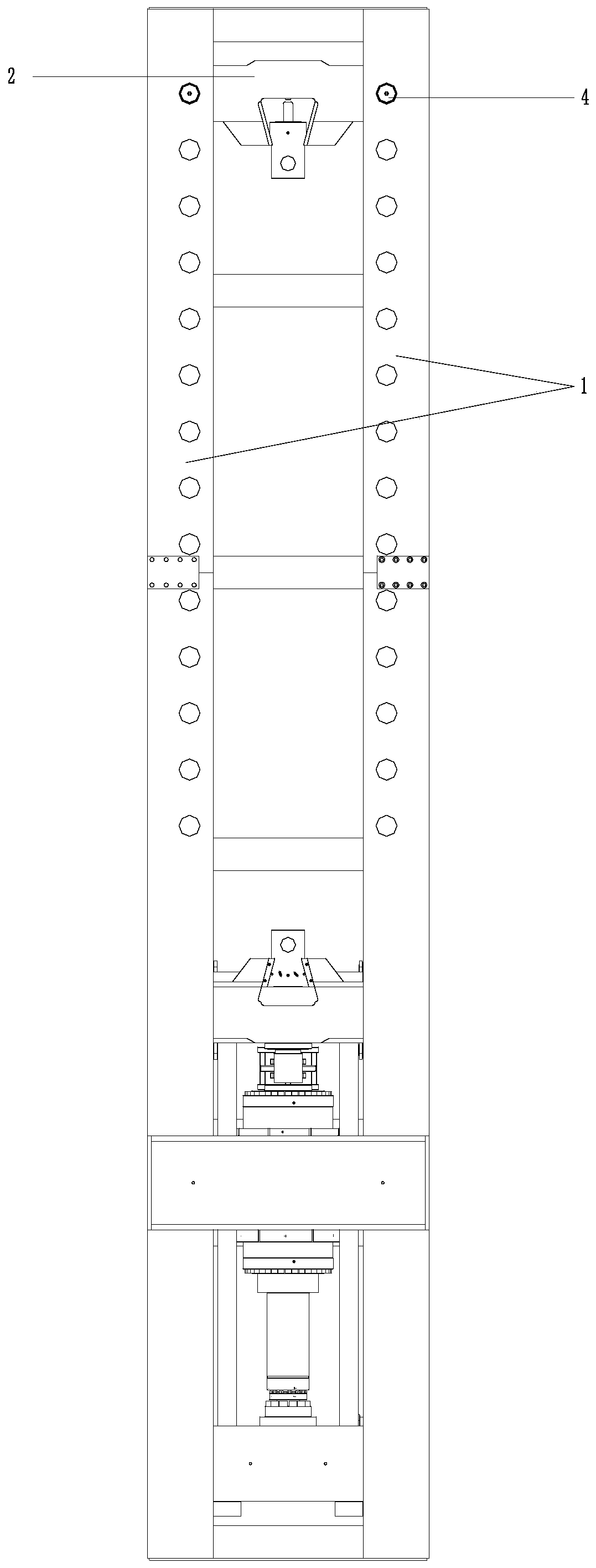

[0024] See figure 1 and figure 2 , a rotationally symmetrical latch mechanism designed in a preferred embodiment of the present invention, which mainly includes: a guide cylinder 3, a latch 4, a threaded rod 5, and a handle 6. The components and their connections are described in detail below.

[0025] The guide tube 3 is cylindrical, and the guide tube 3 is inserted in the positioning hole of the moving beam 2, and the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com