Device for changing slip ring of motor

A slip ring device and slip ring technology, which is applied in the field of tooling for replacing motor slip rings, can solve the problems of inability to replace wind turbine slip rings, shortages, etc., and achieve the effects of saving hoisting costs, improving utilization rates, and reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

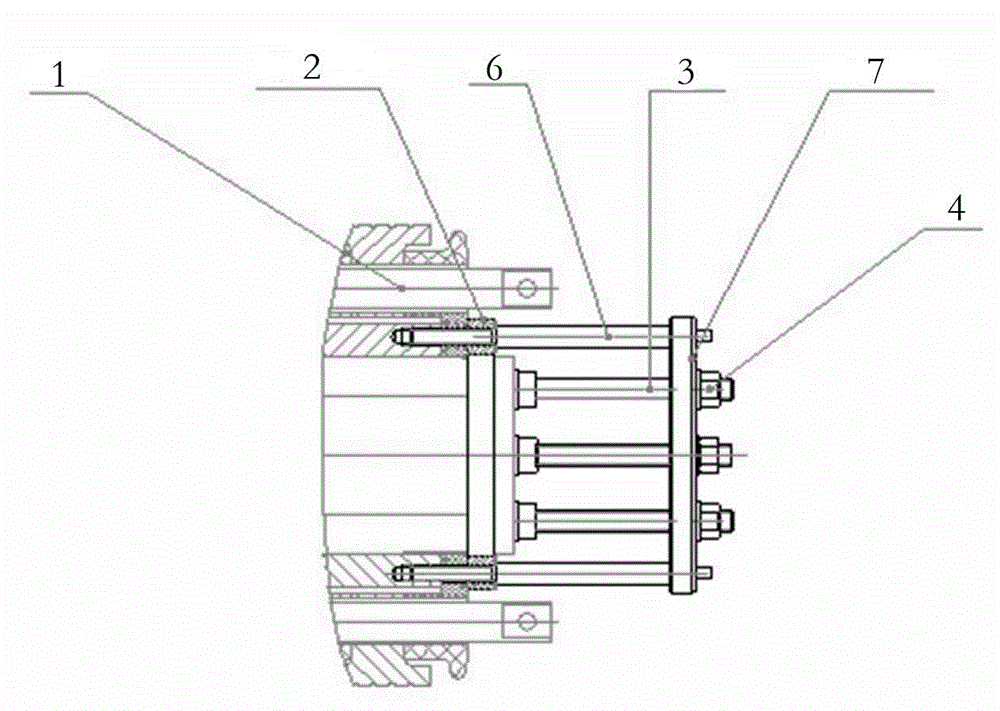

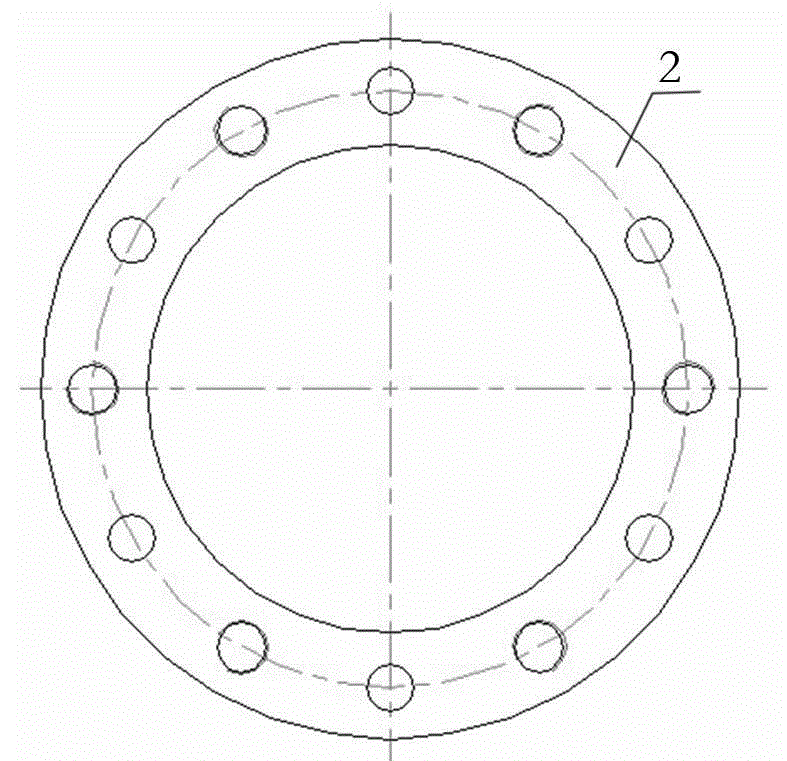

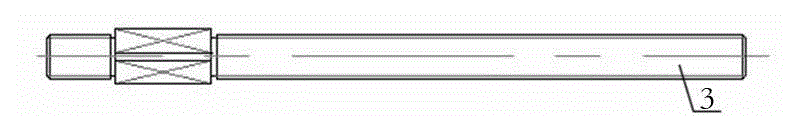

[0014] The motor replacement slip ring device consists of a slip ring protection ring 2 fixed on the end surface of the slip ring 1, a threaded tie rod 3 threaded with the slip ring protection ring 2 or the end surface of the motor shaft, a nut 4 matched with the threaded tie rod 3, and the end surface of the motor shaft. Or the slip ring protection ring 2 is threaded and is provided with the threaded push rod 6 of the shaft shoulder 5, the pressure plate 7 with the threaded pull rod and the threaded push rod passing through the hole. During specific implementation, in order to realize the fixing of the slip ring protection ring 2 and the motor slip ring 1, the slip ring protection ring 2 is provided with evenly distributed fixing holes. At the same time, in order to realize the threaded connection between the threaded pull rod 3 or the threaded push rod 6 and the slip ring protection ring 2, the slip ring protection ring 2 is provided with evenly distributed screw holes.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com