Roof floor-standing support and construction method thereof

A construction method and a floor-to-ceiling technology, which can be applied to pillars, protective buildings/shelters, and earthquake resistance, and can solve problems such as difficulty in ensuring the installation quality of pre-embedded supports, so as to avoid high-altitude welding, ensure compactness, and improve Effect of pour quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

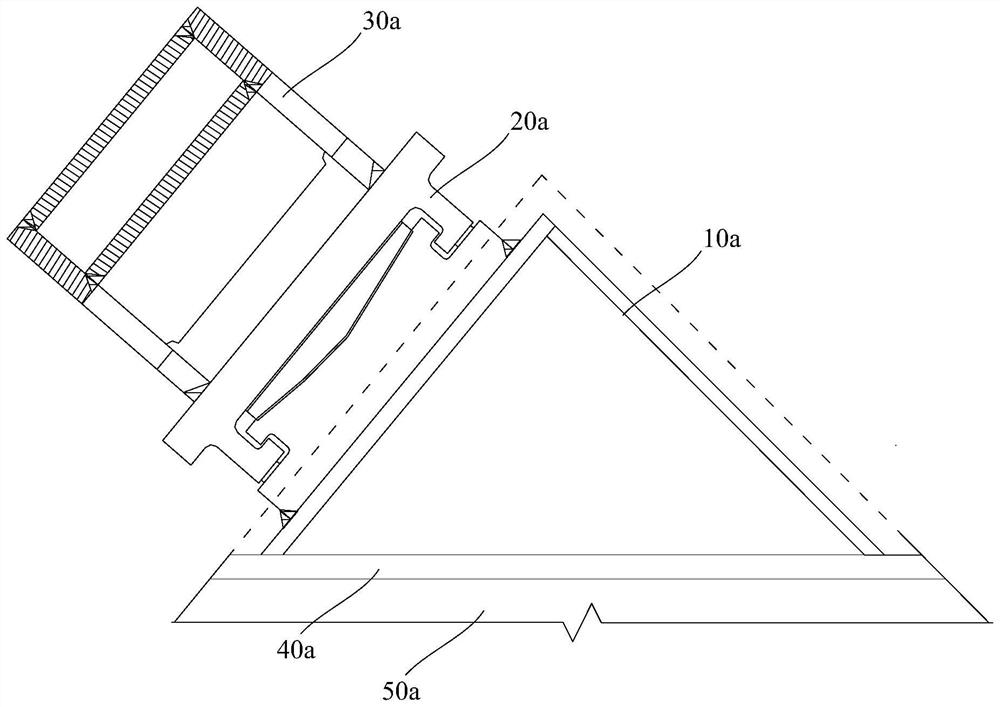

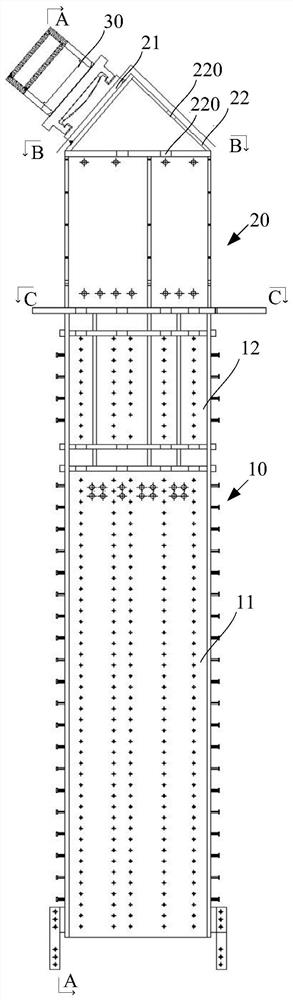

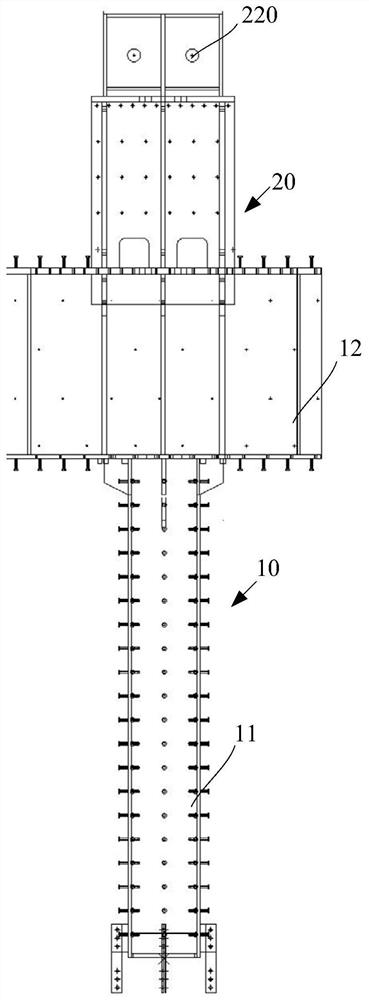

[0051] see figure 2 , showing a front view of an embodiment of the roof floor-standing support of the present invention. Figure 3 is figure 2 A schematic diagram of the A-A orientation. Figure 4 for figure 2 Schematic of the B-B orientation. Figure 5 for figure 2 Schematic of the C-C orientation. combine Figure 2 to Figure 5 As shown, the roof floor-standing support of the present invention includes:

[0052] erect a beam-column frame 10 fixed on the ground;

[0053] The square table frame 20 integrally fixed on the top of the beam-column frame 10, the top of the square table frame 20 forms an obliquely arranged mounting plate 21;

[0054] The concrete poured on the beam-column frame 10 and the square platform frame 20 to form the frame concrete structure; and

[0055] The anti-vibration structure 30 is mounted on the mounting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com