Shear type leakproof grab bucket

A leak-proof and grabbing technology, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of easily damaged storage cargo containers, leakage of cargo loading and unloading, small horizontal area, etc., and achieve good leak-proof effect and grabbing ratio Great, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

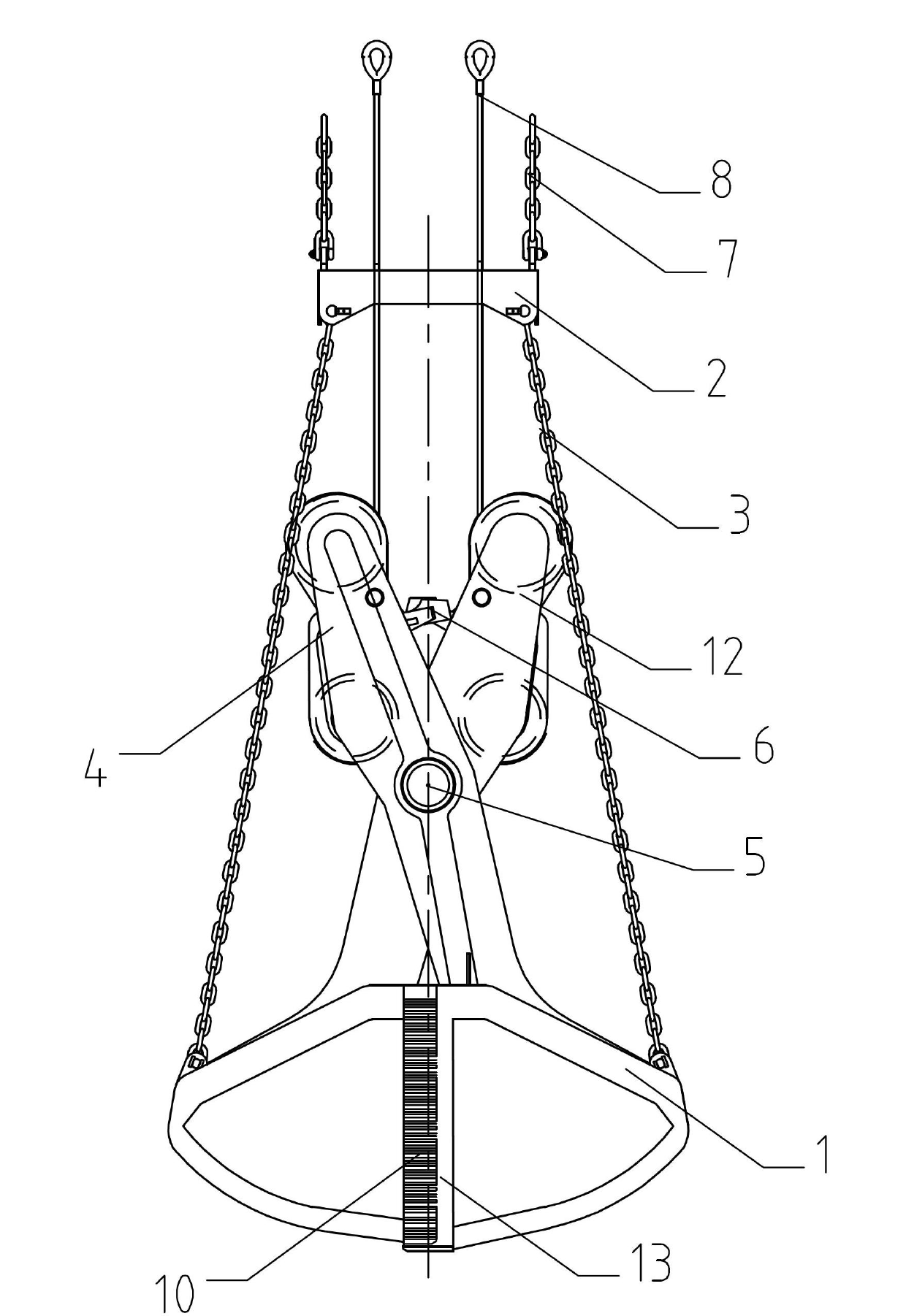

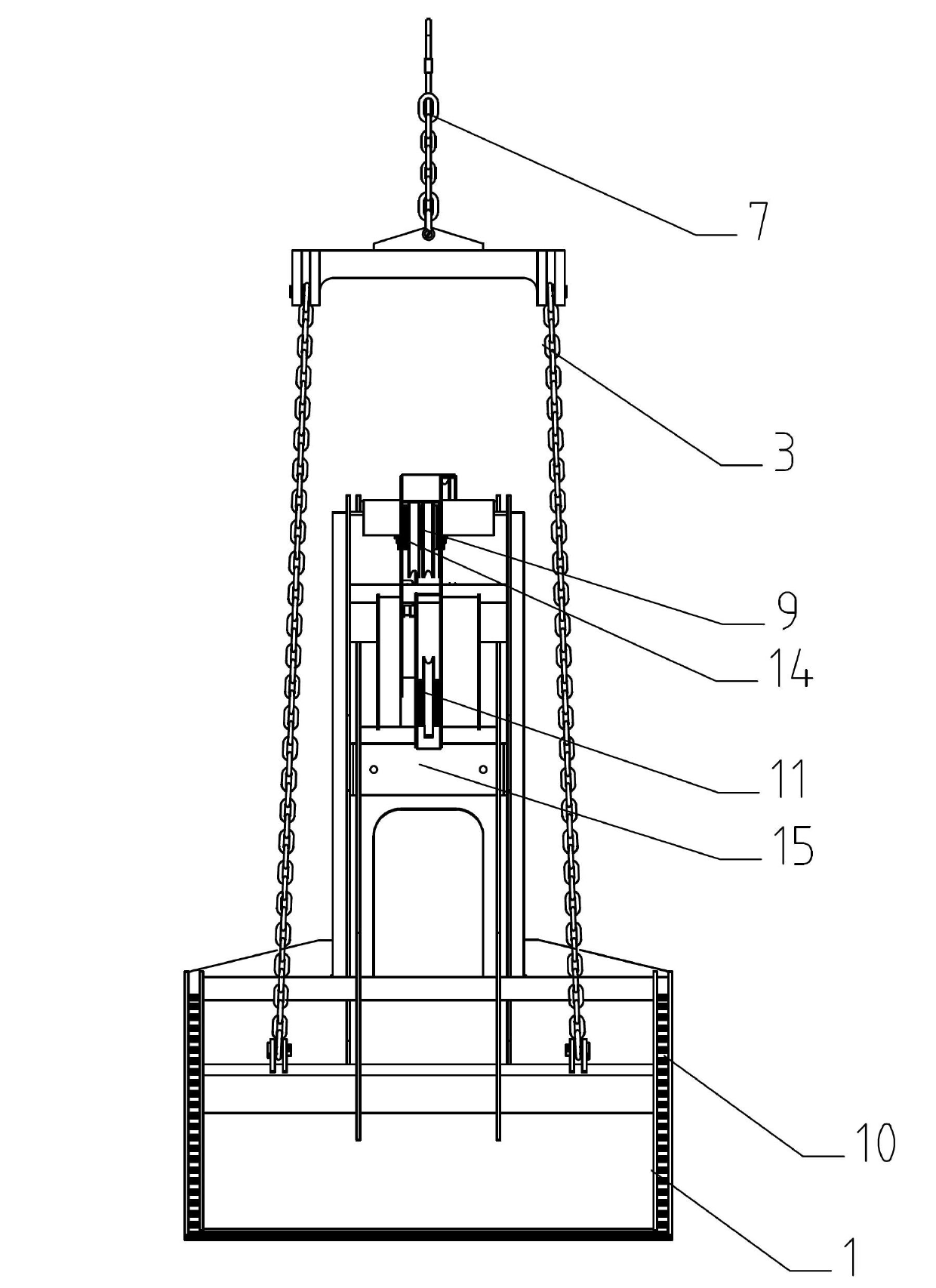

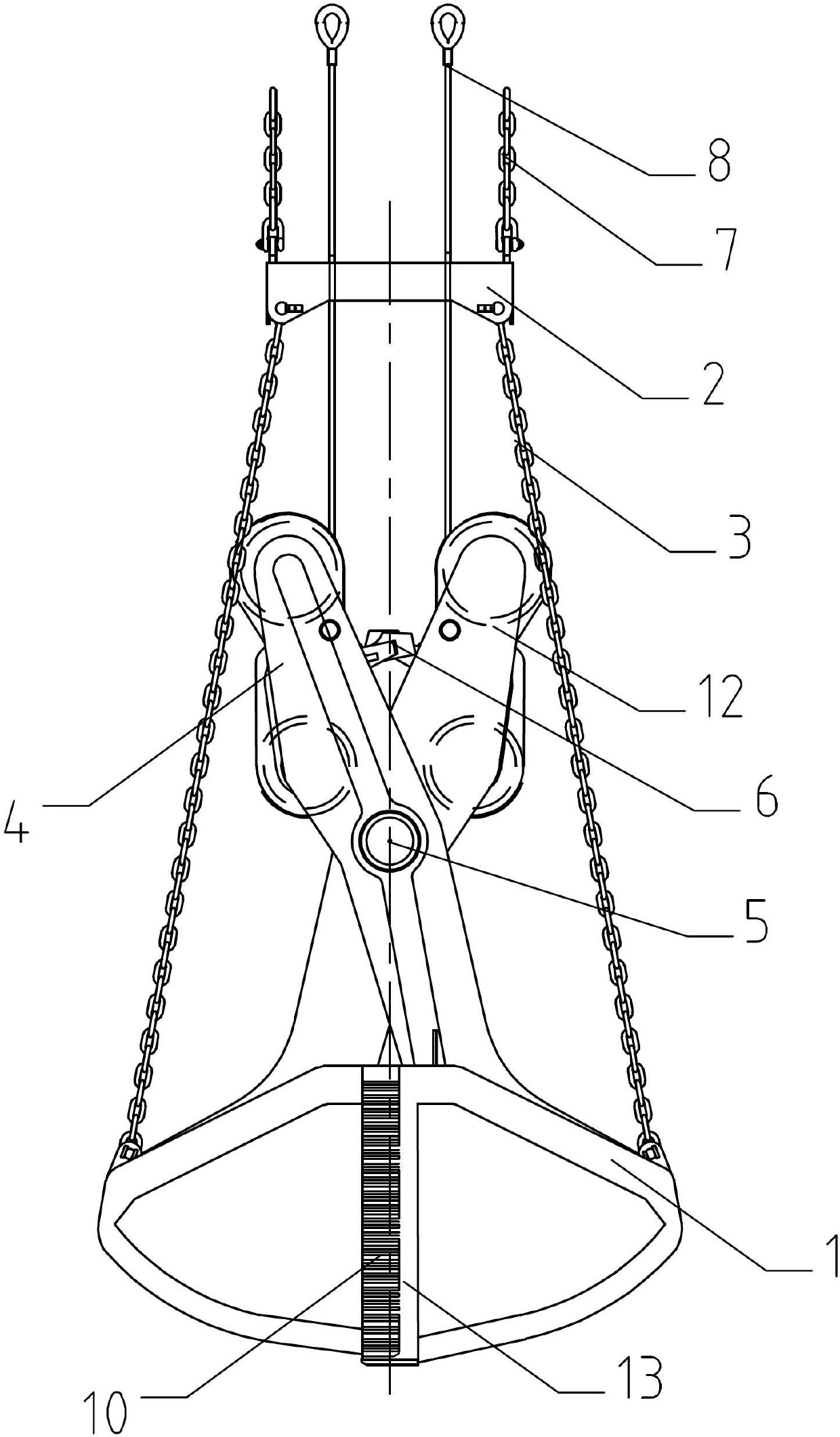

[0012] Such as Figure 1~2 As shown, the present invention mainly comprises funnel-proof funnel body 1, hanger 2, chain 3, left grab bucket arm 4, right grab bucket arm 12, upper pulley block 9 and lower pulley block 11, connect lifting rope 7 above hanger frame 2 two ends , the lower ends of the hanger 2 are connected to the chain 3, and the lower ends of the chain 3 are connected to both sides of the anti-funnel body 1. The anti-funnel body 1 includes two bilaterally symmetrical bucket petals 13, which are connected to the lower ends of the left and right grab arms 4, 12. The left and right grab arms 4, 12 are hinged together by a central pin 5. The left and right grab arms 4, 12 are respectively provided with an upper pulley block 9 and a lower pulley block 11. The upper pulley block 9 includes two pulleys connected by an upper pin shaft 14 . De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com