Vertical type pneumatic hanger

A crane and vertical technology, which is applied in the field of vertical pneumatic cranes, can solve problems such as hydraulic equipment blasting and affecting production, and achieve the effects of ensuring safe production, fast and reliable braking, and easy and flexible adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The process embodiment will be described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

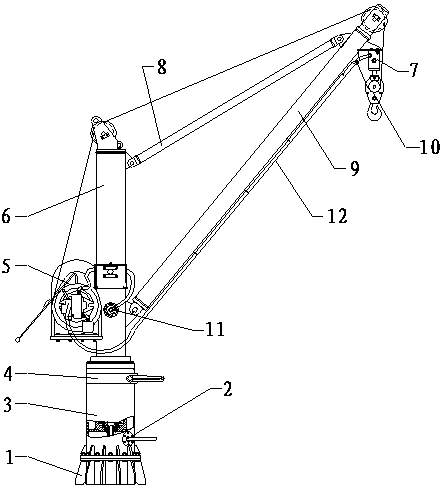

[0024] like figure 1 As shown in the structural diagram of the present invention, a vertical pneumatic crane includes a fuselage 3, an air source inlet 2 fixedly installed on one side of the fuselage 3, a rotating mechanism 4 installed on the fuselage 3, a fixed The frame 6 installed on the rotating mechanism 4, the gear box 5 installed on one side of the frame 6, the boom 9 rotatably installed on one side of the fuselage 3, and rotatably installed on the frame 6 The push rod 8 on the upper part and on the same side as the suspender 9, the hook 10 installed at the rotating end of the suspender 9, and the handle bar 12 passing through the bracket below the suspender 9, the push rod The rotating end of 8 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com