Formula of antique facing black brick and production method of formula

A production method and technology for blue bricks, which are applied in the field of the formulation of antique veneer blue bricks, can solve the problems of not reflecting the vicissitudes of the years and the heavy history, destroying the historical value of buildings, and high production costs of blue bricks, so as to achieve the effect of enhancing the antique. , the effect of reducing costs and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Such as Figures 1 to 3 Shown, a kind of formula of antiquated finish blue brick, by weight ratio, is made up of following raw material: 94% of the cement slurry that No. 425 Portland cement is made, 4% of concrete colorant, nano-TiO 2 Anti-aging agent 0.3%, strong electrolyte inorganic salt early strength agent 0.7%, nano plasticizer 0.3%, naphthalenesulfonate water reducer 0.2%, carbon fiber 0.5%, and the cement paste is cement with a water-cement ratio of 0.25 Pure pulp.

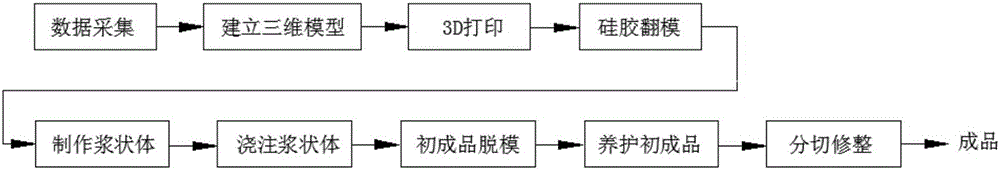

[0041] The production method of above-mentioned archaized finish blue brick, comprises the following steps:

[0042] Step S1. According to No. 425 Portland cement, 94% of cement slurry, 4% of concrete colorant, nano TiO 2 Anti-aging agent 0.3%, strong electrolyte inorganic salt early strength agent 0.7%, nano plasticizer 0.3%, naphthalenesulfonate water reducer 0.2%, carbon fiber 0.5%, and the cement paste is cement with a water-cement ratio of 0.25 The percentage by weight of the net pulp is ta...

Embodiment 2

[0049] Such as Figures 1 to 3 As shown, the formula of an antique facing blue brick is composed of the following raw materials in proportion by weight: 92% of cement paste made of No. 425 Portland cement, 5.5% of concrete colorant, nano-TiO 2Anti-aging agent 0.4%, strong electrolyte inorganic salt early strength agent 0.8%, nano plasticizer 0.4%, naphthalene sulfonate water reducer 0.3%, carbon fiber 0.6%, and the cement slurry is cement with a water-cement ratio of 0.25 Pure pulp.

[0050] The production method of above-mentioned archaized finish blue brick, comprises the following steps:

[0051] Step S1. According to No. 425 Portland cement, 92% of cement slurry, 5.5% of concrete colorant, nano TiO 2 Anti-aging agent 0.4%, strong electrolyte inorganic salt early strength agent 0.8%, nano plasticizer 0.4%, naphthalene sulfonate water reducer 0.3%, carbon fiber 0.6%, and the cement slurry is cement with a water-cement ratio of 0.25 The percentage by weight of the net pulp...

Embodiment 3

[0058] Such as Figures 1 to 3 As shown, the formula of an antique facing green brick is composed of the following raw materials in proportion by weight: 96% of cement paste made of No. 425 Portland cement, 2.5% of concrete colorant, nano-TiO 2 Anti-aging agent 0.2%, strong electrolyte inorganic salt early strength agent 0.6%, nano plasticizer 0.2%, naphthalene sulfonate water reducer 0.1%, carbon fiber 0.4%, and the cement slurry is cement with a water-cement ratio of 0.25 Pure pulp.

[0059] The production method of above-mentioned archaized finish blue brick, comprises the following steps:

[0060] Step S1. According to No. 425 Portland cement, 96% of cement slurry, 2.5% of concrete colorant, nano TiO 2 Anti-aging agent 0.2%, strong electrolyte inorganic salt early strength agent 0.6%, nano plasticizer 0.2%, naphthalene sulfonate water reducer 0.1%, carbon fiber 0.4%, and the cement slurry is cement with a water-cement ratio of 0.25 The percentage by weight of the net pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com