Auxiliary robot for ultrasonic flaw detection

An ultrasonic and robotic technology, applied in the direction of material analysis, instruments, and scientific instruments using sonic/ultrasonic/infrasonic waves, can solve the problem of high labor intensity of inspectors, and achieve the effect of reducing missed work, speeding up efficiency, and improving inspection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

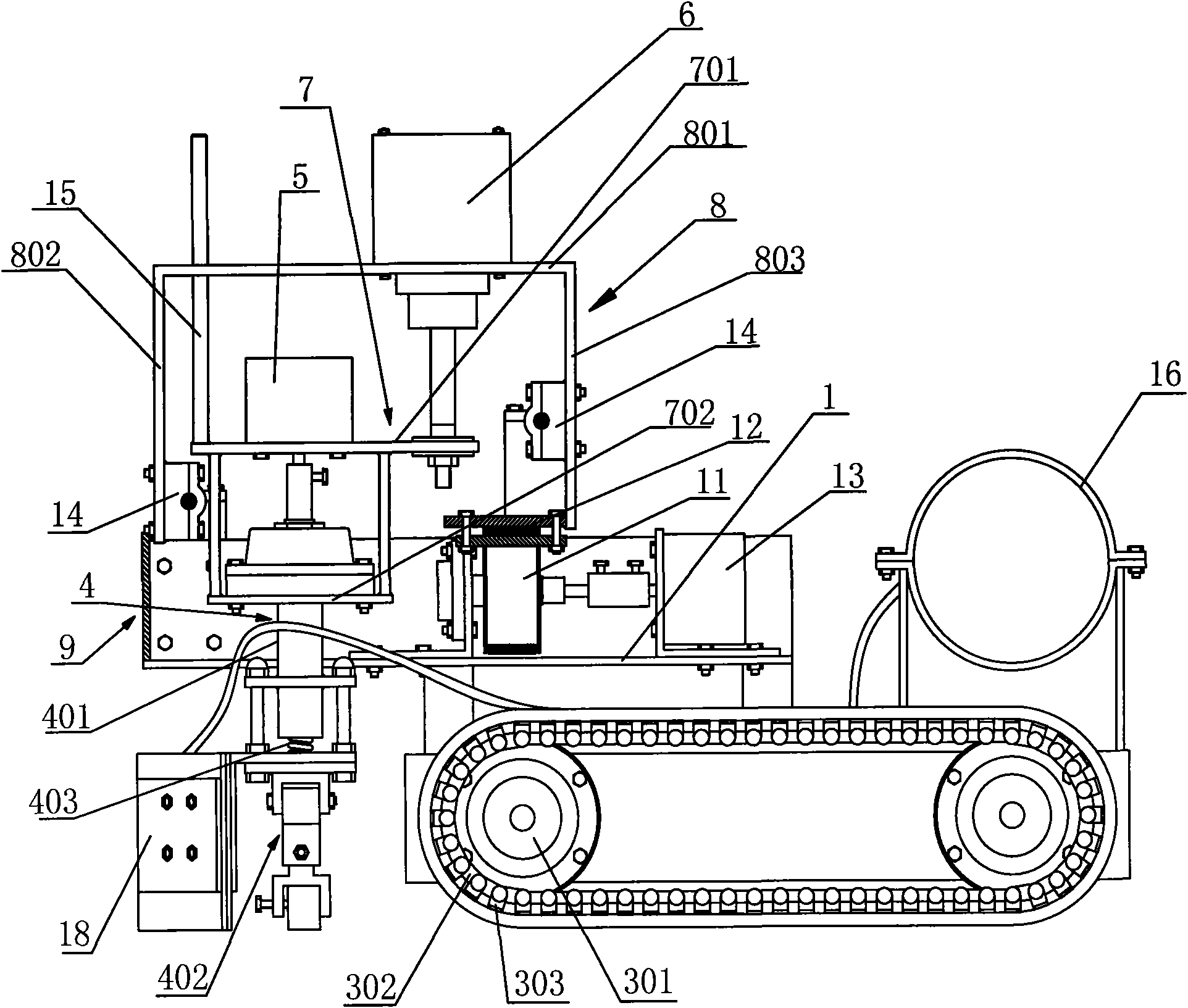

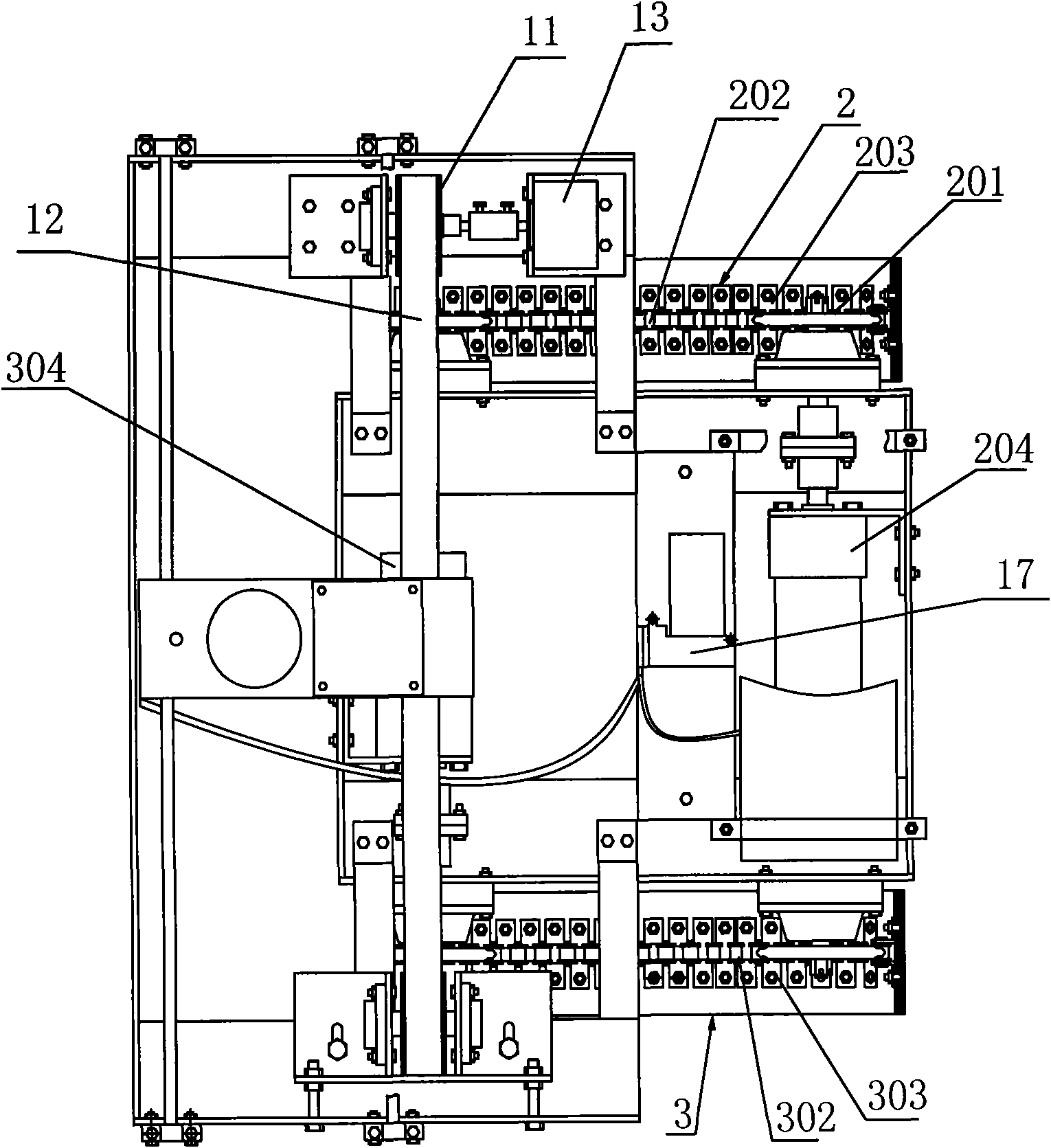

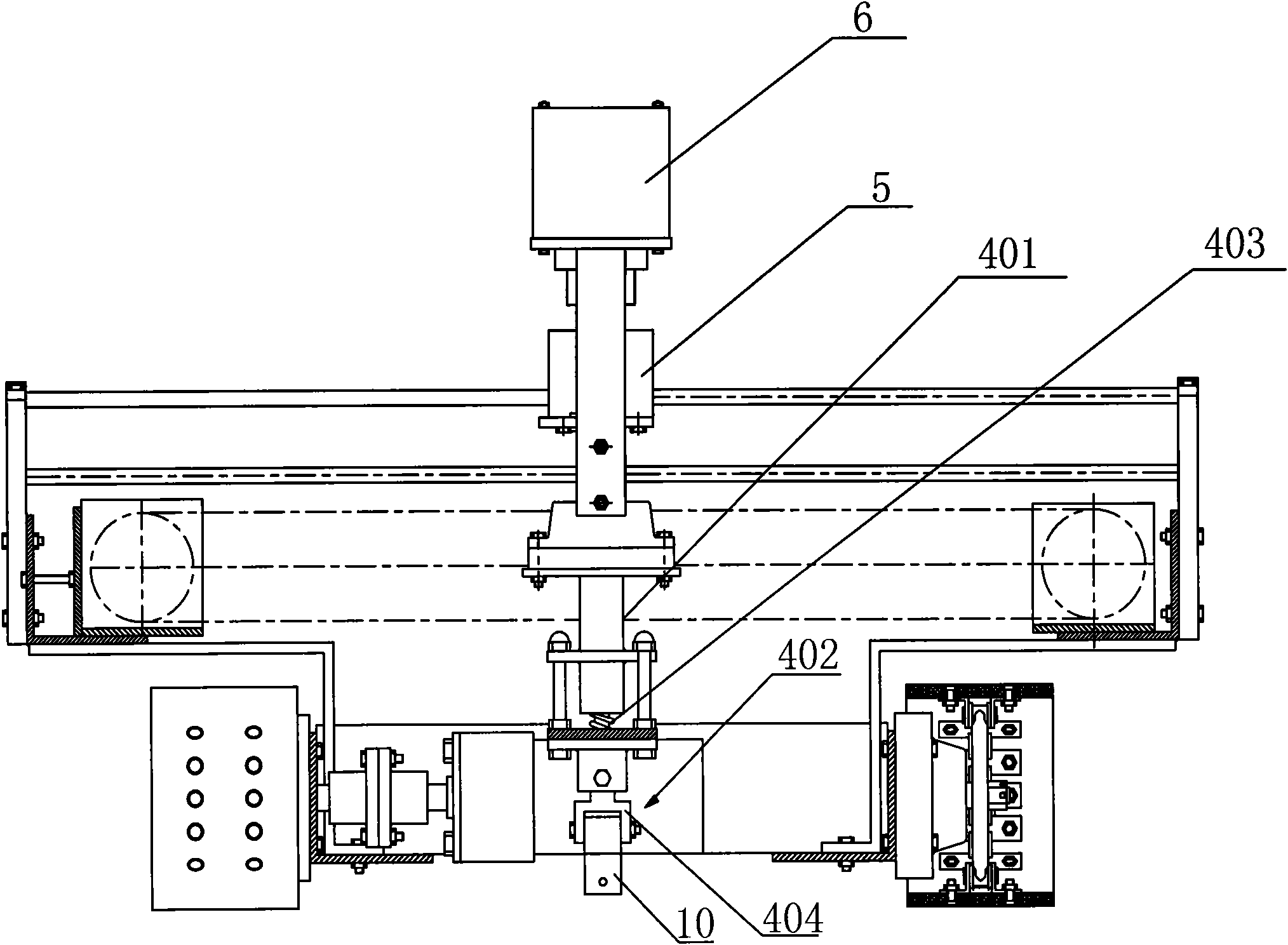

[0018] to combine figure 1 , figure 2 and image 3 , an ultrasonic flaw detection auxiliary robot, its frame 1 is provided with a frame walking mechanism. The frame traveling mechanism is provided with two magnetic walking crawlers, namely the No. 1 magnetic walking crawler 2 positioned on the left side of the frame and the No. 2 magnetic walking crawler 3 positioned at the right side of the frame. The No. 1 magnetic walking crawler 2 is provided with a sprocket wheel, a transmission chain 202, a magnetic crawler 203 and a first driving motor 204. The first driving motor 204 is located at the rear side of the frame traveling mechanism, and the magnetic walking crawler where it is located is the No. 1 magnetic walking crawler. The rear sprocket 201 in 2 is connected, and the first drive motor 204 drives the sprocket to rotate, and drives the magnetic crawler belt to advance through the transmission chain. The No. 2 magnetic walking crawler 3 is provided with a sprocket whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com