Giant non-standard trapezoidal thread processing method

A trapezoidal thread and processing method technology, applied in the direction of electrical program control, digital control, etc., can solve problems such as no way to find, achieve the effect of improving processing quality and precision, and improving processing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

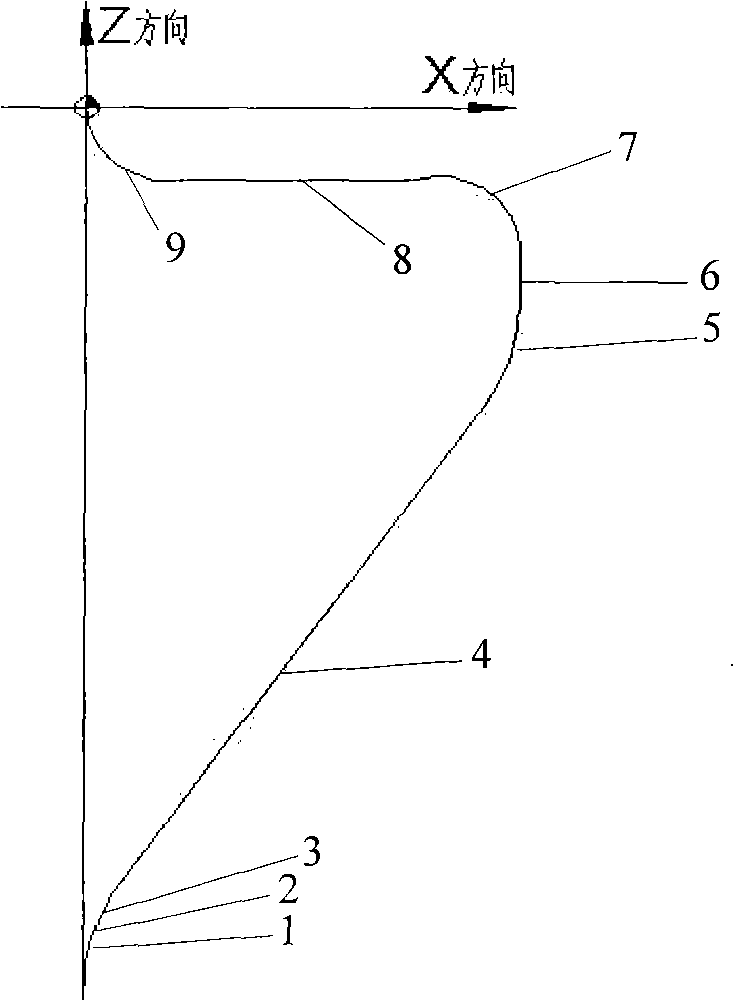

[0036] see figure 1 , the cross-section of the S2099×P50 giant non-standard trapezoidal thread to be processed in this embodiment is approximately a right-angled trapezoid. The entire thread has a pitch of 50mm and a tooth depth of 22mm, and is composed of 9 line segments. See figure 1 , the specific parameters are: the first line segment 1 is a convex arc of R10, the second line segment 2 is a line segment of 22.5 degrees, the third line segment 3 is a convex arc of R4, and the fourth line segment 4 is a line segment of 35.25 degrees , the fifth line segment 5 is a concave arc of R10, the sixth line segment 6 is a line segment of 90 degrees, the seventh line segment 7 is a concave arc of R4, the eighth line segment 8 is a line segment of 0 degrees, and the ninth line segment 9 is a line segment of R4 Convex arc; except for the seventh line se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com