Numerical control mill groove machine tool

A machine tool and grinding tank technology, which is applied in the direction of grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of low part processing efficiency, long production cycle, low production efficiency, etc., and achieve stable processing quality and high degree of automation , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

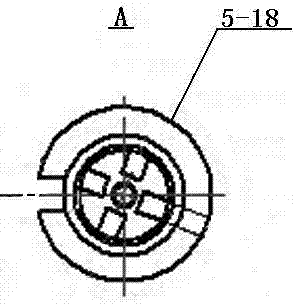

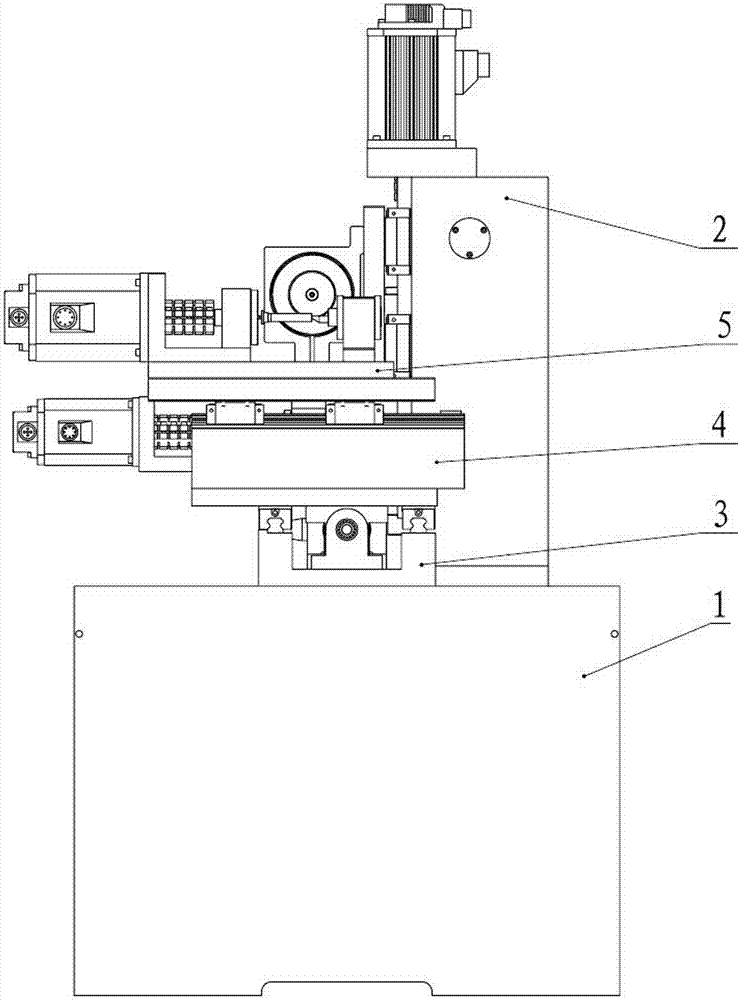

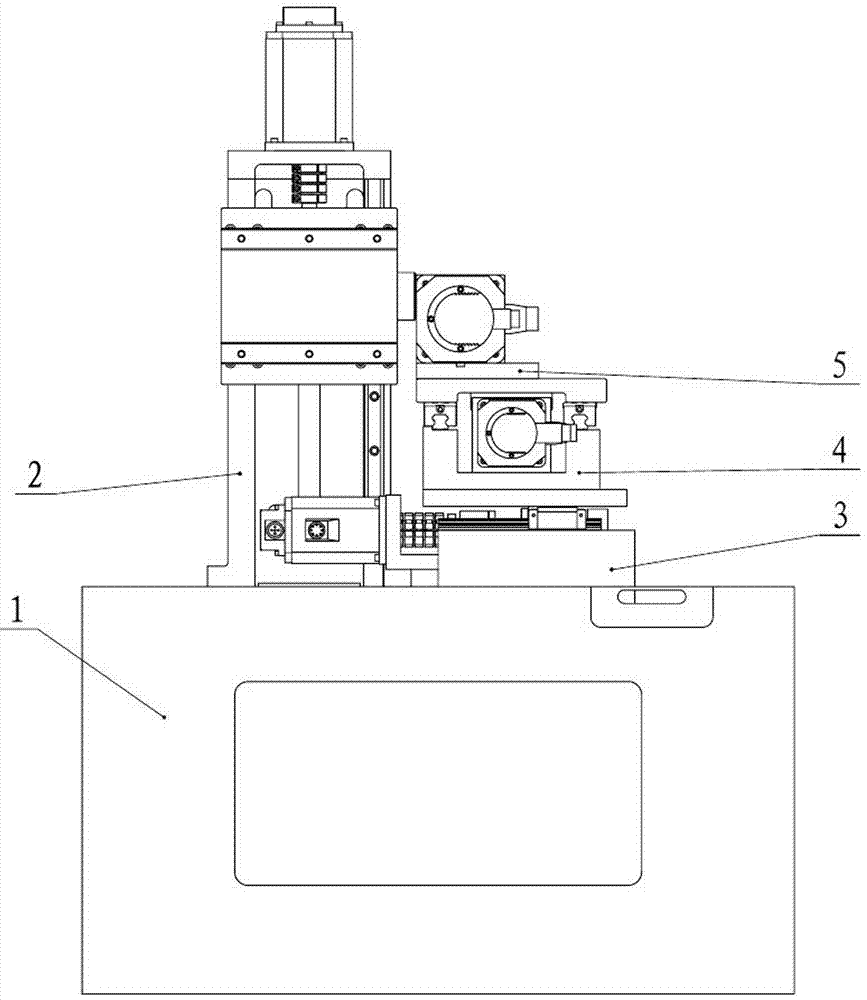

[0037] Refer to attached Figure 1-13 , The CNC groove grinding machine tool is composed of a bed 1, a lifting and moving part unit 2, a front and rear moving part unit 3, a left and right moving part unit 4 and a rotary fixture part unit 5.

[0038] The bed 1 is a casting machine body.

[0039] The lifting and moving part unit 2 is installed on the upper part of the bed 1 . The lifting and moving part unit 2 includes a lifting column 2-1, a lower end cover 2-2, a hexagon socket head screw 2-3, a deep groove ball bearing 2-4, a lower bearing seat 2-5, and a ball screw Deputy 2-6, lifting nut 2-7, hexagon socket head screw 2-8, lifting slide plate 2-9, upper bearing seat 2-10, two angular contact bearings 2-11, spacer ring 2-12, Upper end cover 2-13, hexagon socket head screw three 2-14, bushing 2-15, lock nut one 2-16, electric spindle base 2-17, hexagon head bolt 2-18, lifting motor seat 2-19 , Coupling one 2-20, hexagon socket head screw four 2-21, lifting servo motor 2-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com