Floor made of hard floor boards and production process of the floor board

A technology of floor boards and floors, which is applied in the direction of manufacturing tools, building structures, chemical instruments and methods, etc., and can solve problems such as inapplicable connection of floor boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

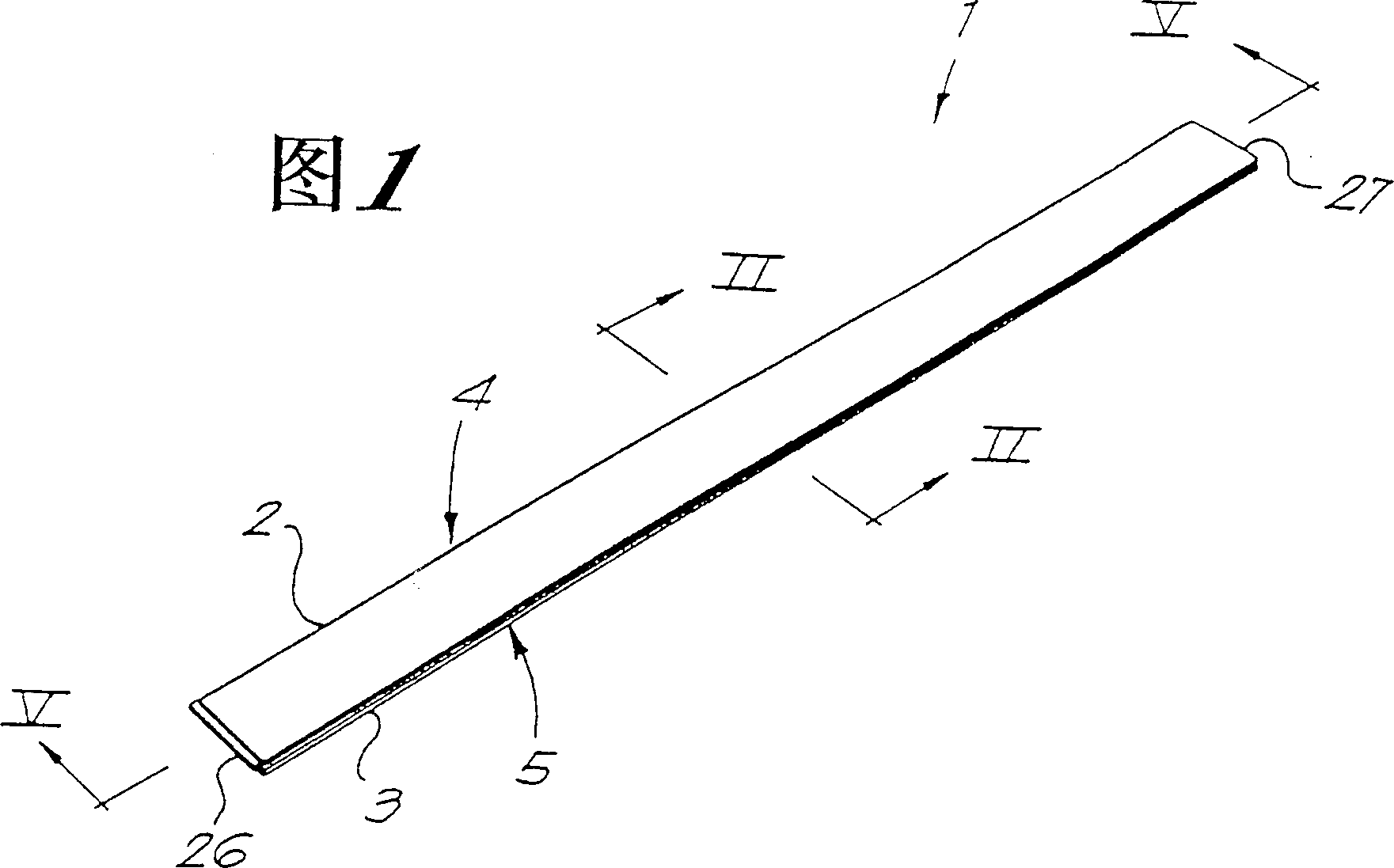

[0091] The invention relates to a floor consisting of hard floorboards 1 as shown in FIG. 1 .

[0092] These floorboards 1 can be of various shapes, such as rectangular, square, or other shapes.

[0093] In the most preferred form of embodiment, they are processed into elongated shapes, for example, as shown in Figure 1, of 1 to 2 meters in length, and the thickness can also vary, but preferably 0.5 to 1.5 cm, and 0.8 cm better.

[0094] Each floorboard 1 has connecting portions 4-5 at least at its two opposite ends 2-3, so that two adjacent floorboards 1 can fit together.

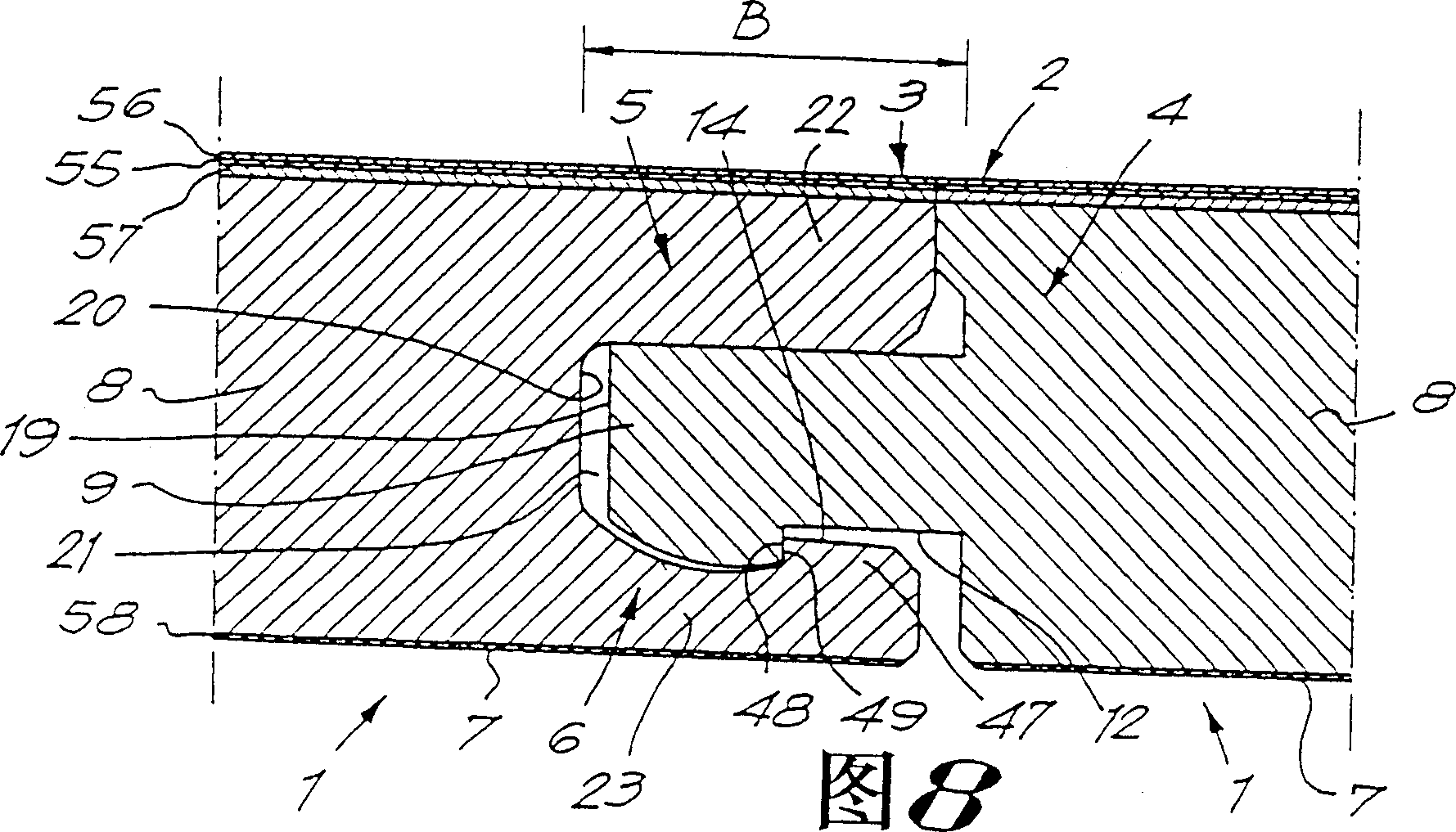

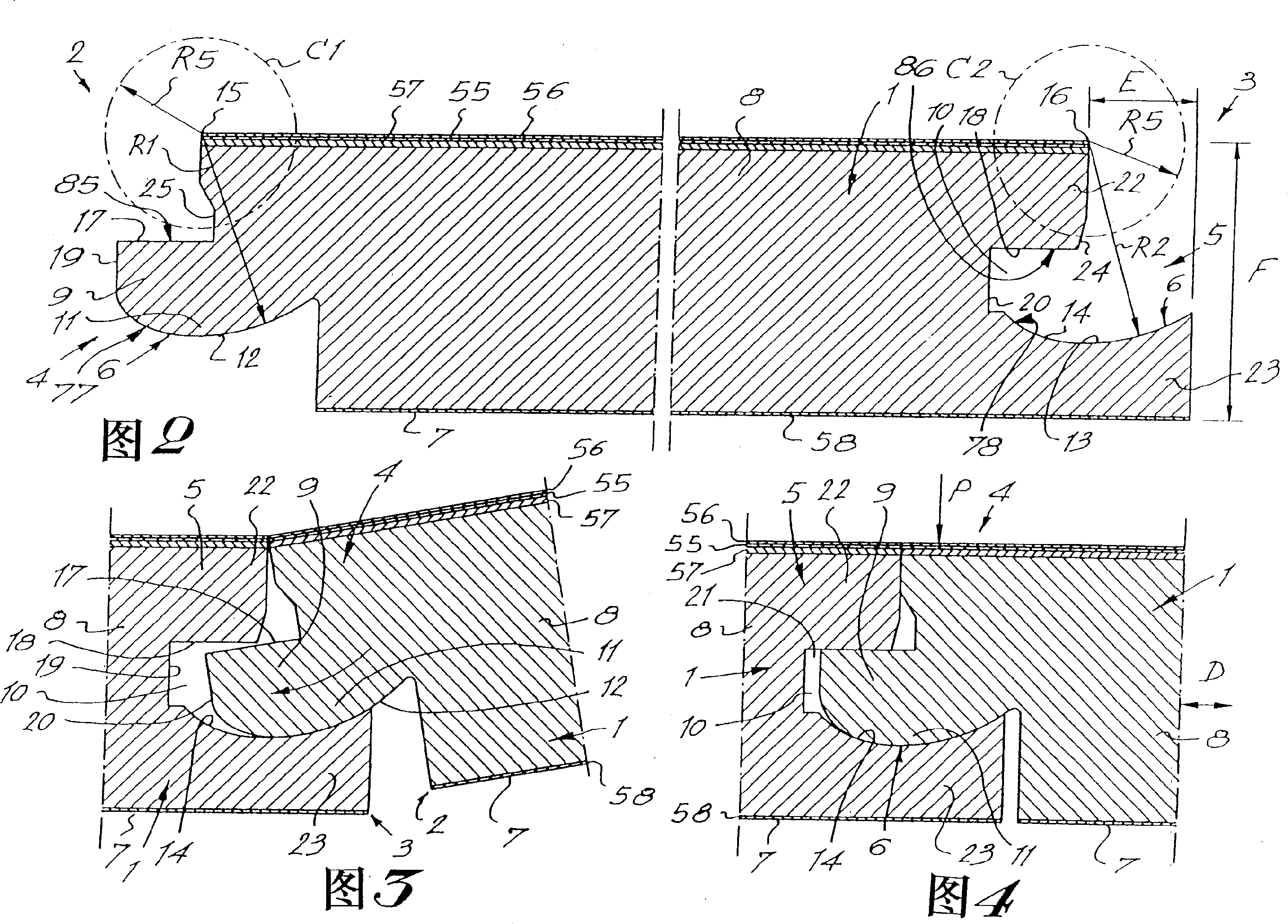

[0095] As shown in Figures 2 to 4, the connecting part 4-5 of the present invention is provided with an integrated mechanical locking part 6 which prevents the two cooperating floorboards from moving perpendicular to their respective ends 2-3 and parallel to each other. Separation in the direction D of the bottom edge 7 of the mating floorboard 1; the connection part 4-5 and the locking part 6 are integr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com