Composite board automatic production line

An automatic production line, composite board technology, used in plywood presses, other plywood/plywood appliances, veneer presses, etc. The effect of less interference from factors, reduced labor intensity and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

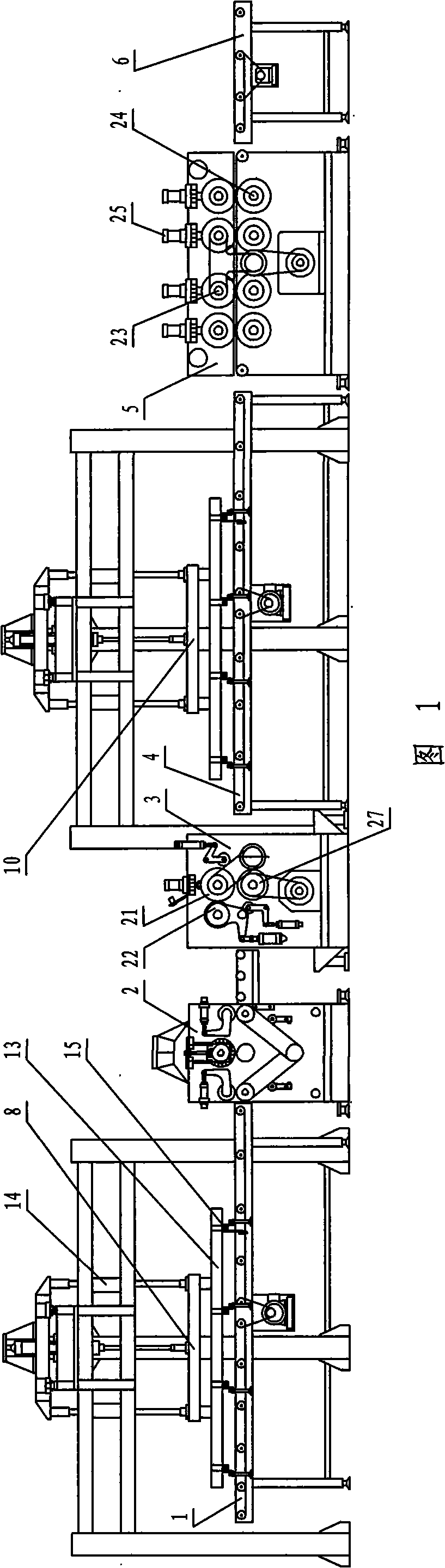

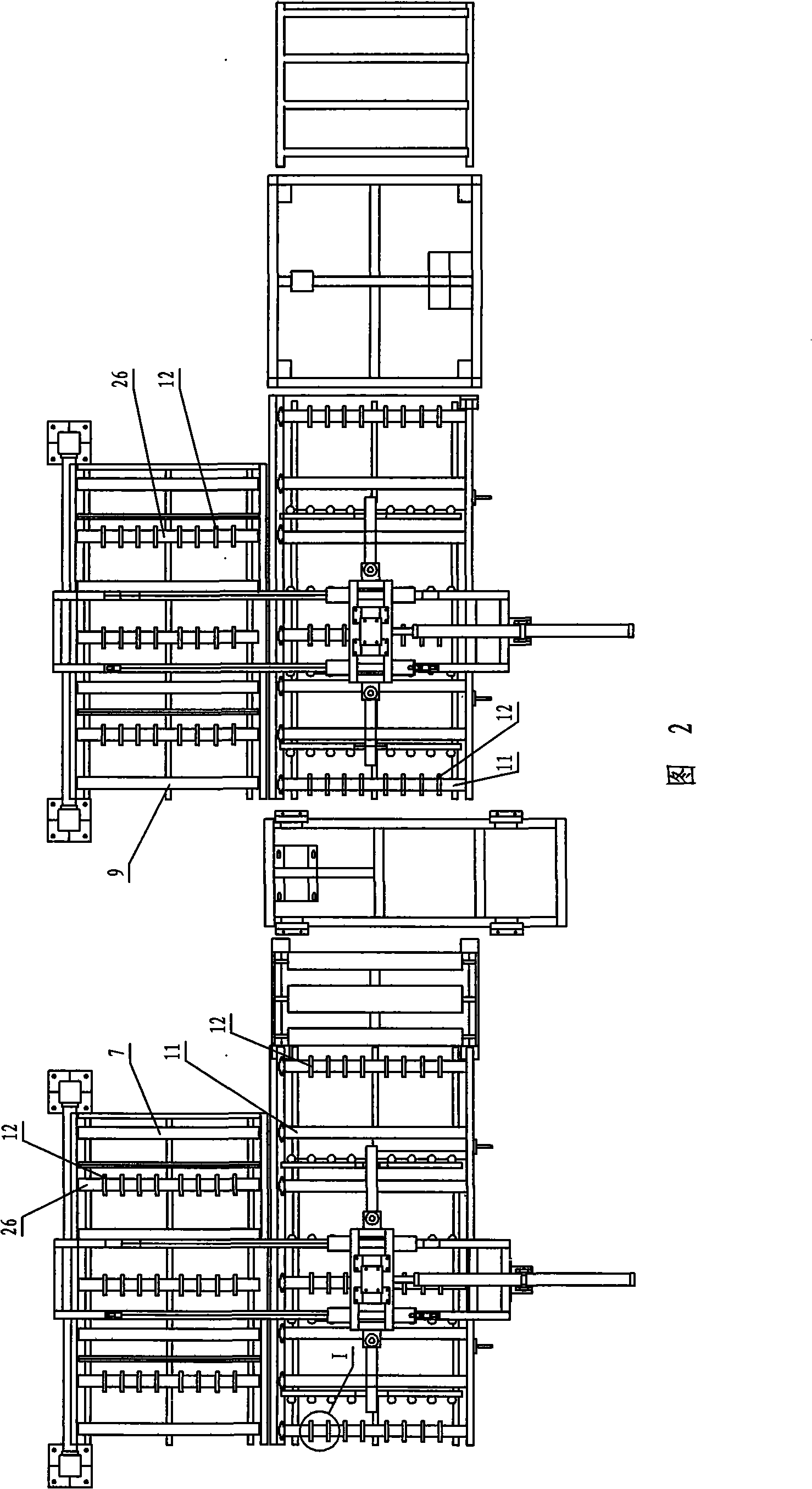

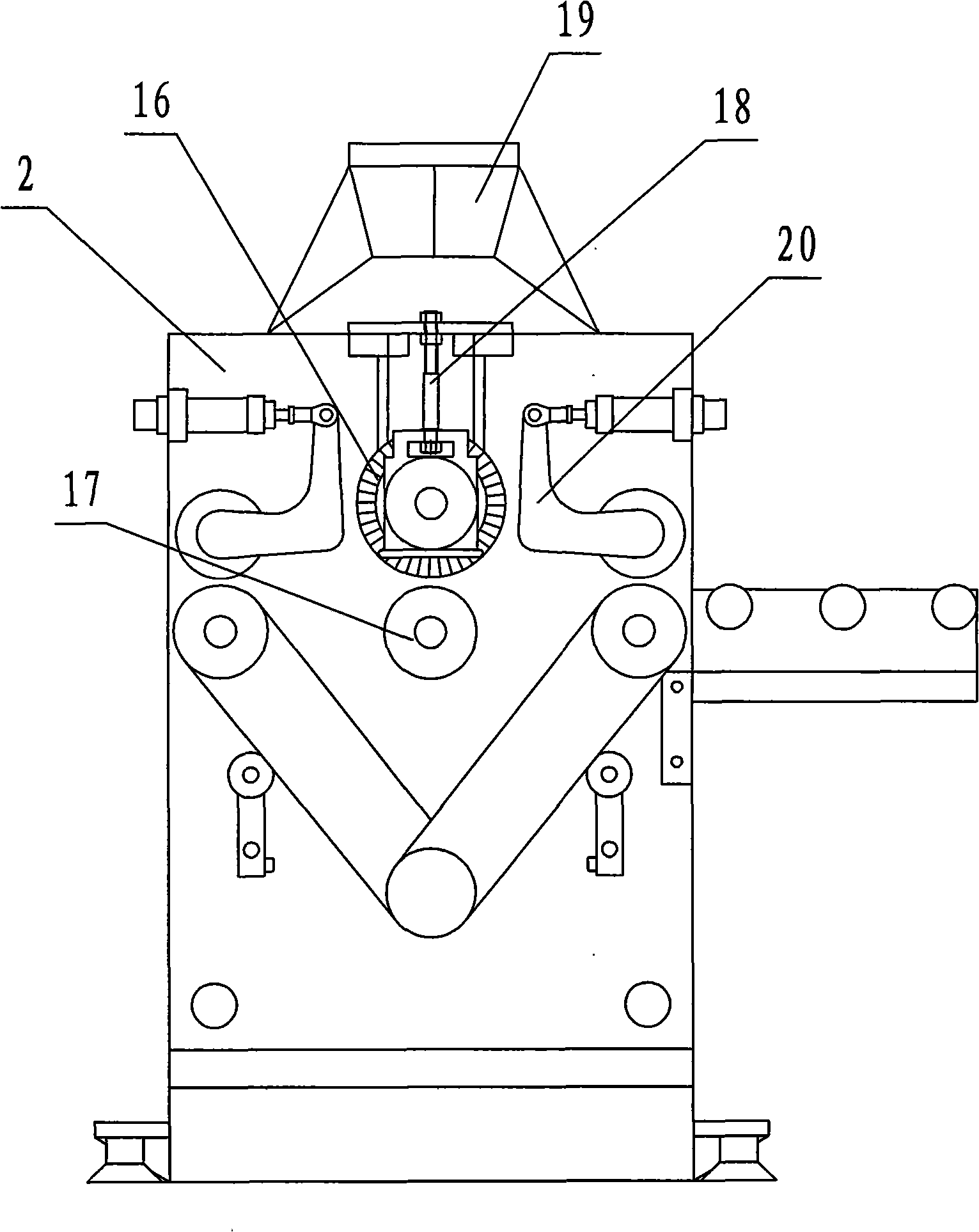

[0024] Figure 1 Figure 2 image 3 Figure 4 An automatic production line for composite boards is shown, which is used to bond and compact the substrate and panel of composite boards. The production line has a roller conveying device 1, a substrate surface cleaning device 2, and an automatic glue spraying device 3 arranged in sequence , conveying and aligning laminating device 4, laminating and compacting device 5 and board output conveying device 6, substrate stacking device 7 is arranged next to roller conveyor device 1, and above roller conveyor device 1 and substrate stacking device 7 is The substrate transfer device 8 is provided with a panel stacking device 9 next to the conveying alignment laminating device 4 , and a panel transfer device 10 is located above the conveying alignment laminating device 4 and the panel stacking device 9 .

[0025] Both the substrate transfer device 8 and the panel transfer device 10 use a vacuum chuck 13 to transfer the substrate and the pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com