Medium plate splicing machine

A jigsaw machine and jigsaw technology, applied to other plywood/plywood utensils, wooden veneer joints, wood processing utensils, etc., can solve the problems of reduced material utilization, waste of resources, and inability to realize automation, etc., to achieve reduction The effect of production labor cost, improvement of work efficiency and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

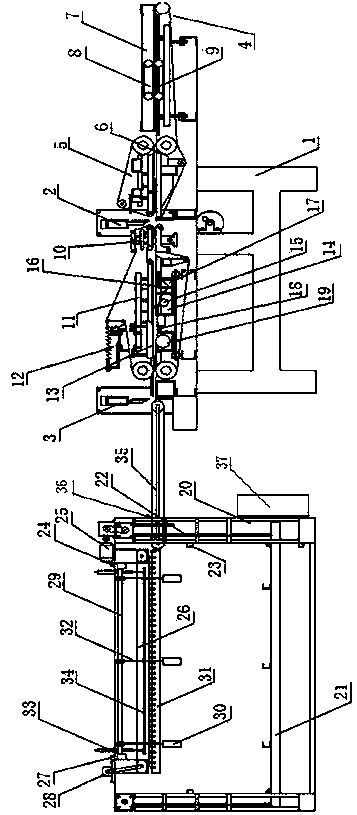

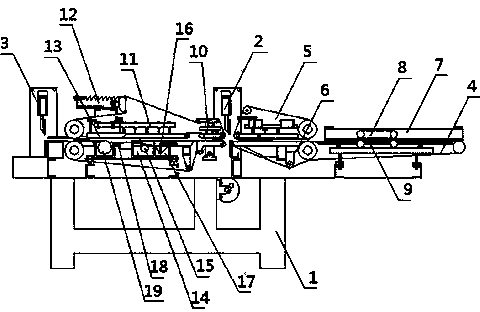

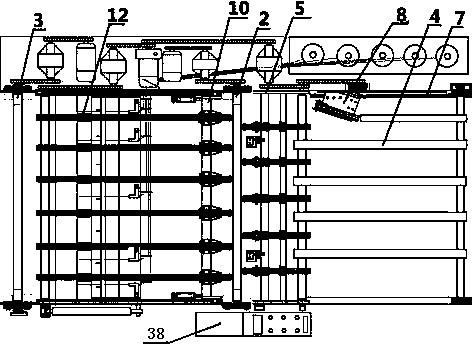

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Accompanying drawing is that the present invention is described in detail as follows with reference to accompanying drawing of description:

[0017] The middle board jigsaw machine is a kind of automatic equipment for splicing the finished middle board (sandwich) or waste materials together according to the set size. This machine is the latest and the first in China. Its operation process is: feeding, correction, flattening, pressure feeding, edge trimming, gluing, crimping, splicing, finished product cutting, and automatic palletizing at one time. The breakthrough innovation of this product, using the PLC coding program, realizes the fully automatic control of the machine. The whole machine has the characteristics of low price, convenient use, less cutting, energy saving, and low failure. It can be operated by one person. It has a good splicing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com