Laminated sheets of tabasheer core layer and the outer bamboo bottom layer and the processing method

A laminated board and core layer technology, applied in the direction of chemical instruments and methods, wood processing equipment, layered products, etc., can solve the problems of low raw material utilization, few processes, and large waste, and achieve low cost, few processes, and expansion The effect of raw material source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

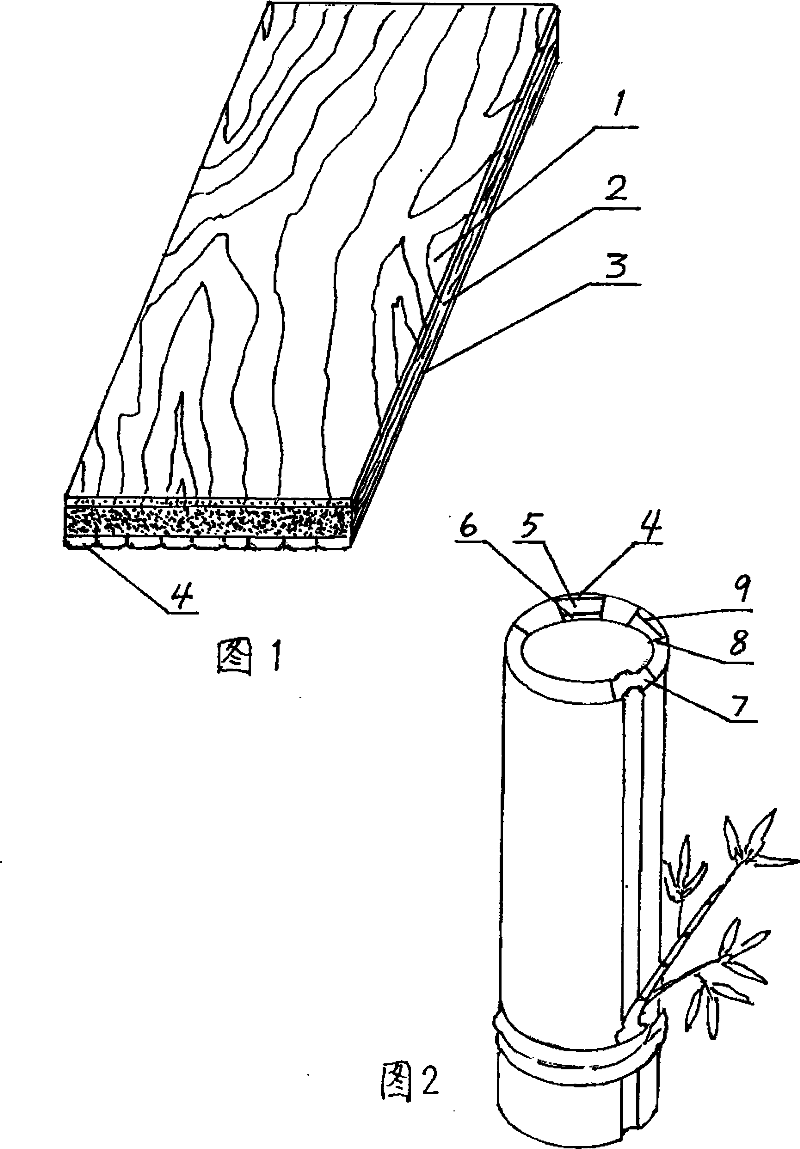

[0033]Embodiment 1: with the four-year-old moso bamboo pole, except the bamboo base and the bamboo tip, the cut length is 1500mm bamboo section, the inner and outer joints are removed, the diameter is split into 17mm wide thick bamboo slices, and then the string is cut into three layers, bamboo green slices 4. Bamboo meat slices 5, bamboo yellow slices 6, and bamboo green slices 6 have a thickness of 4mm at the center line. Cook or carbonize with steam. After drying, cut off the thin edges on both sides to increase the side glued surface. Glue the sides, vertically horizontal Arranged neatly, with the plane facing upwards and the curved surface facing downwards, two adjacent green bamboo pieces are arranged upside down at intervals, so that the assembled boards will not become trapezoidal flat plates, and the bamboo green boards are pressed sideways as the bottom layer of the laminated board; then the bamboo yellow strings Splitting or radially splitting and pressing to form ba...

Embodiment 2

[0034] Embodiment 2: be used as indoor floor, then bamboo section is long 1000mm, and bamboo meat sheet 5 strings are split again, and roll is rolled into bamboo meat connecting silk sheet, thick 2mm, wide 20mm, carry out micro-carbonization treatment, soak phenolic glue, the solidification of glue Content 4%, be spread on the bamboo yellow core layer 2 as described in embodiment 1 after drying and make surface layer 1, pressure 30Mpa, heating 140 ℃, hot pressing 60min, all the other are with embodiment 1.

Embodiment 3

[0035] Embodiment 3: As an interior wall decoration board, the core layer 2 and the bottom layer 3 are prepared as in Example 1, the bottom layer 3 is facing outward, the core layer 2 is facing inwardly against the wall, and the bamboo green board is facing outwardly to show the bamboo country style.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com