Production technology for melamine ecological plate

A melamine and production process technology, applied in the field of plate processing, can solve the problems of easy damage, complicated process, short life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

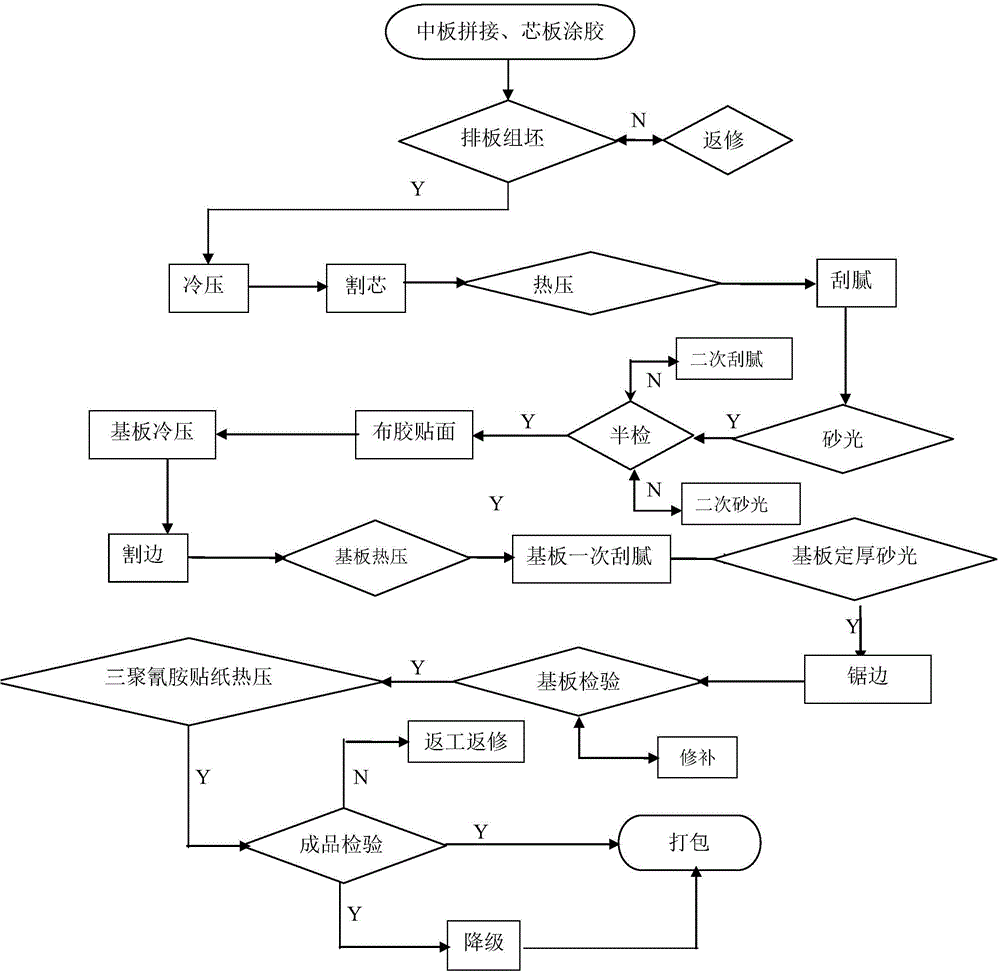

Image

Examples

Embodiment

[0039] A kind of production technology of melamine ecological board, this technology specifically comprises the following steps:

[0040] (1) Splicing of the middle plate: splicing the middle plate of the required size through hot melt adhesive and glue line, and the required size is 2480mm in length and 1260mm in width;

[0041] (2) Core board glue: apply the adjusted glue evenly on the core board through the glue machine;

[0042] (3) Arrangement of boards: the middle boards are arranged on the glued core boards in turn;

[0043] (4) cold pressing: the middle plate and the core plate are carried out the cold pressing process after the slab is assembled, and the cold pressing is 60 minutes, and the pressure is controlled at 12Mpa to obtain the preliminarily formed slab semi-finished product;

[0044] (5) Core cutting: repair the semi-finished slabs that have been cold-pressed and have defects on both sides;

[0045] (6) Hot pressing: use hot pressing to speed up the curing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com