Pile mould with draw-pull type movable feed ports and construction method

A pull-out and feeding port technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of increasing the filling coefficient, increasing the power, reducing the quality of concrete, etc., to prevent the decrease of stress concentration and reduce the drop. Height, the effect of reducing the filling factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

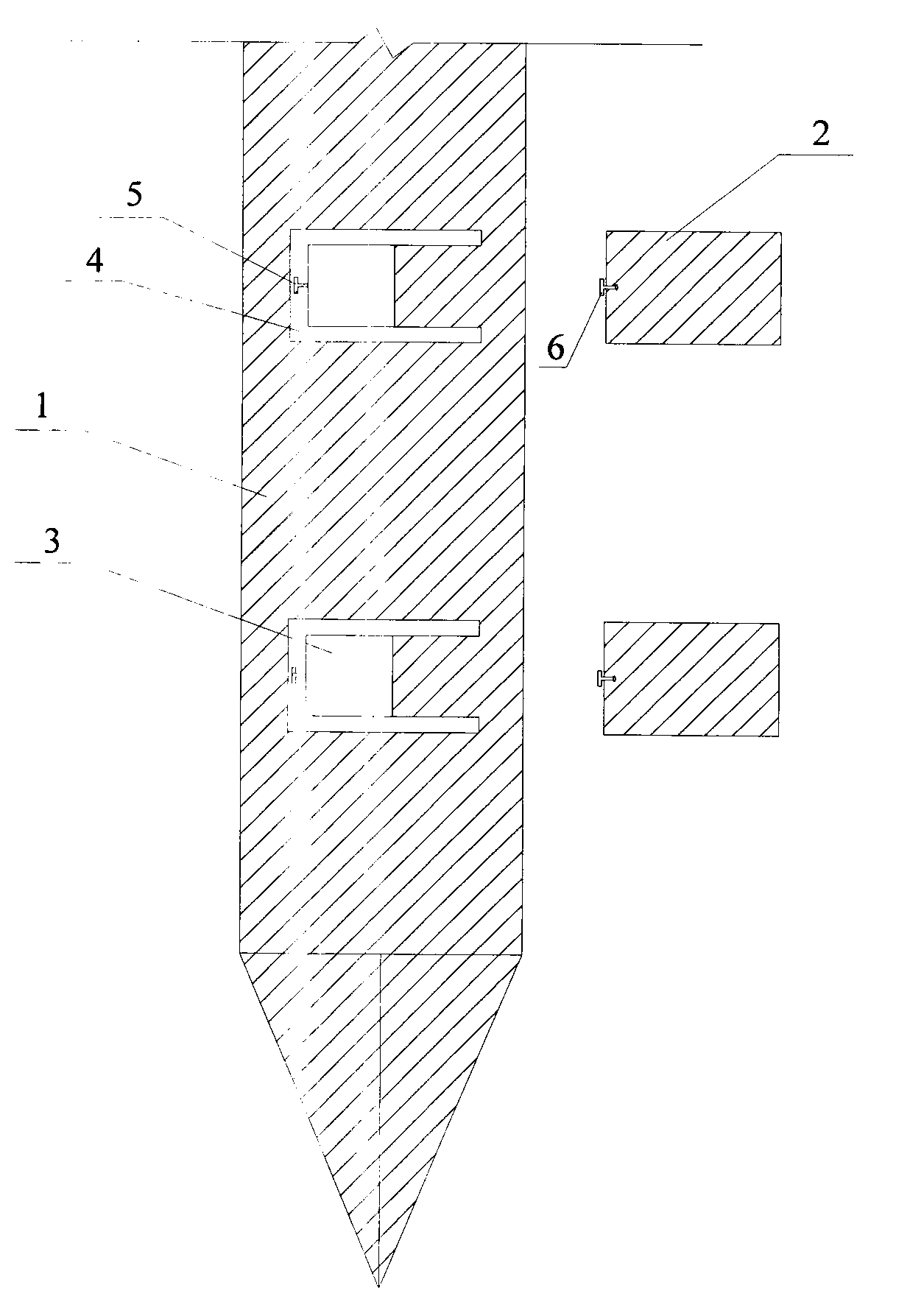

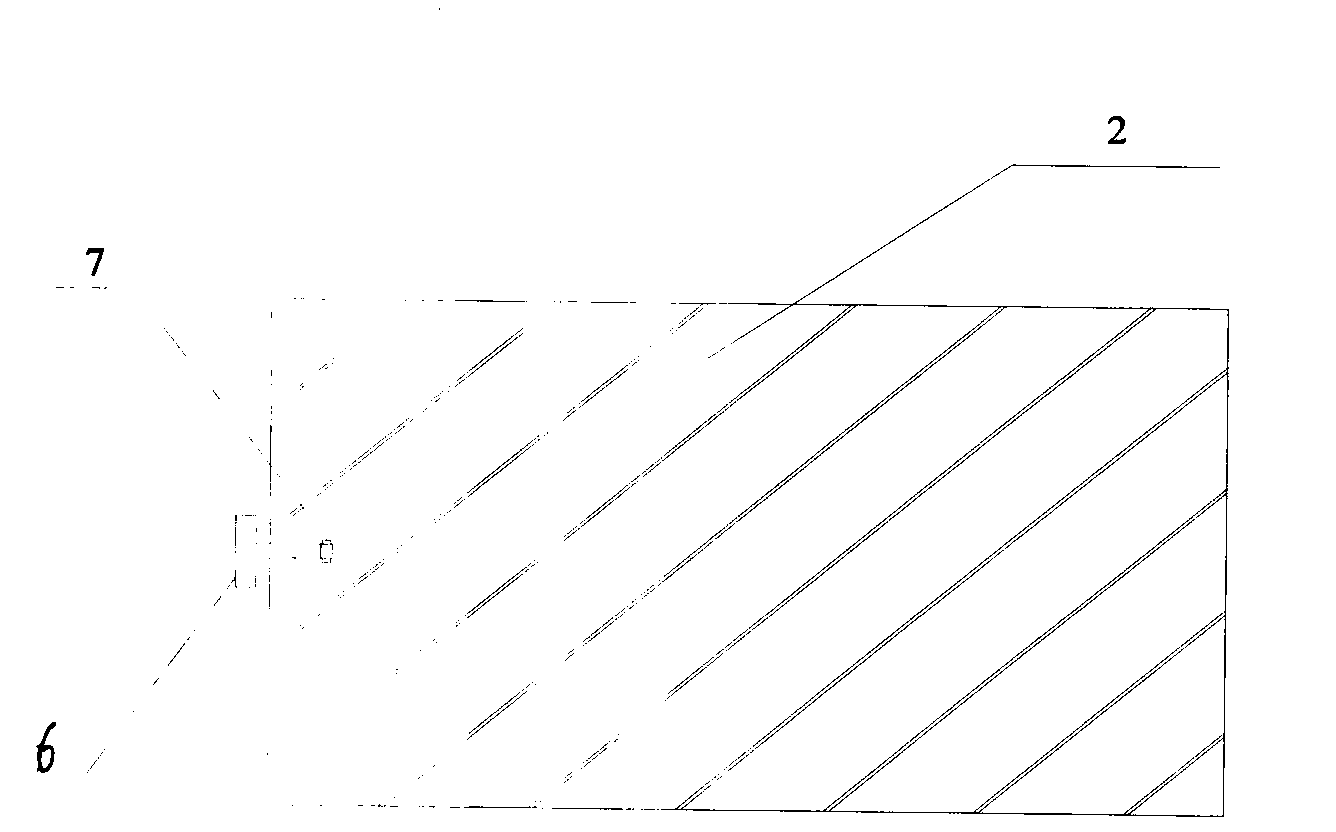

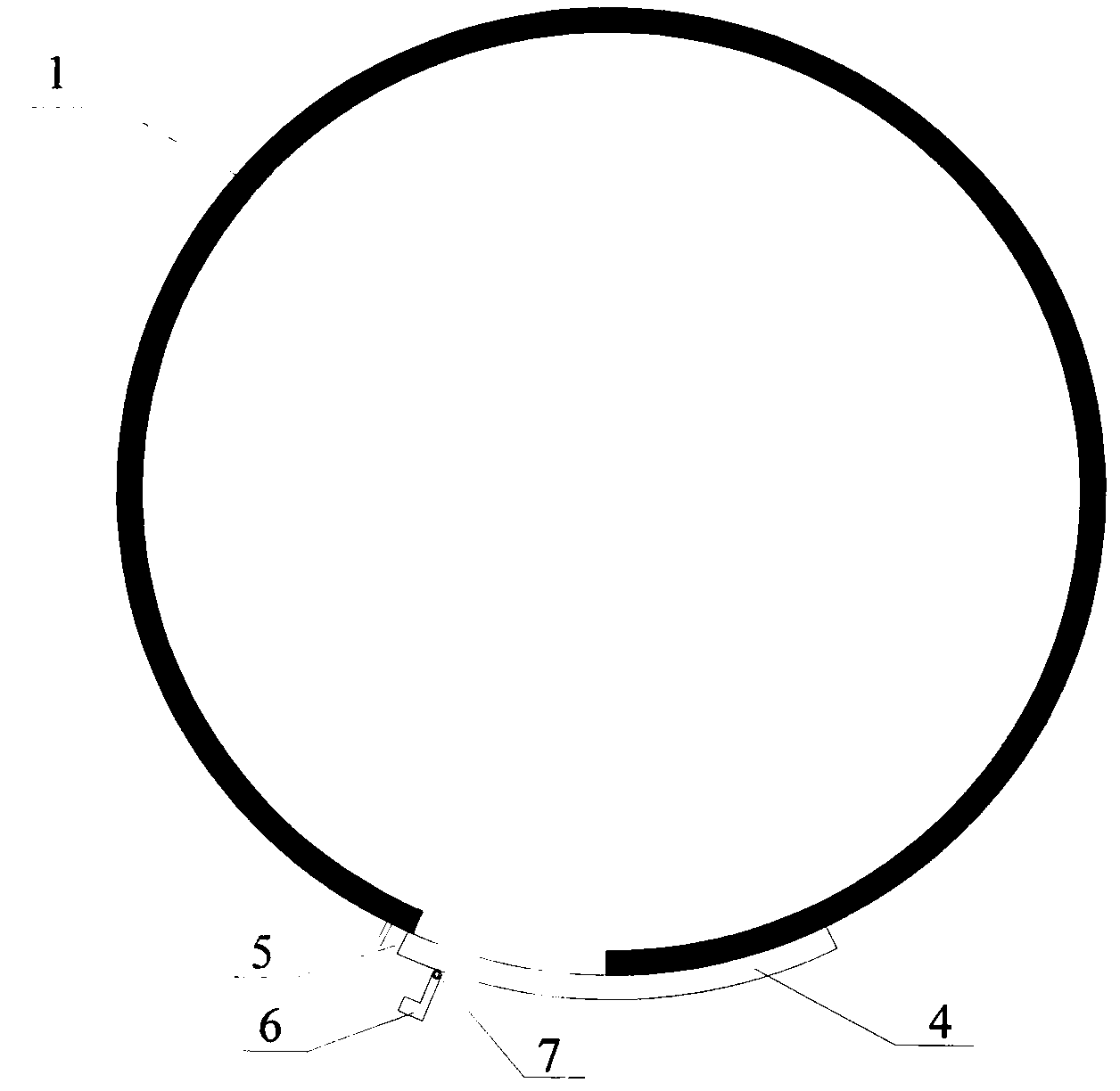

[0042] Such as Figure 1 ~ Figure 3 Shown:

[0043] For the pile formwork with pull-type movable feed inlets, multiple pull-type movable feed inlets are arranged on the side of pile form 1, arranged from top to bottom; the pull-type movable feed inlets are opened by (U-shaped) track 4, Hole 3, arc-shaped insert plate 2, movable connector 6, etc.; opening 3 is a hole opened on the side of the pile form, and track 4 is fixedly connected to the periphery of the pile form of opening 3; track 4 is U-shaped, and the inner side Set or connect waterproof rubber gaskets; the movable connector 6 on the arc board 2 is T-shaped, and is connected with one end on the arc board 2 through a connecting hinge 7; a card slot 5 is set in the middle of the bottom of the track 4, and the movable connector 6 matches the draw-in slot 5, and can be inserted into the draw-in slot 5 to fix the arc-shaped inserting plate 2, and the arc of the arc-shaped inserting plate 2 matches the circular side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com