Cable locating jig and cable wire stripping method based on the same

A technology for positioning fixtures and cables, which is applied in the directions of equipment, circuits, and electrical components for dismantling/armoring cables. It can solve problems such as low efficiency and difficulty, and achieve the effect of easy fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

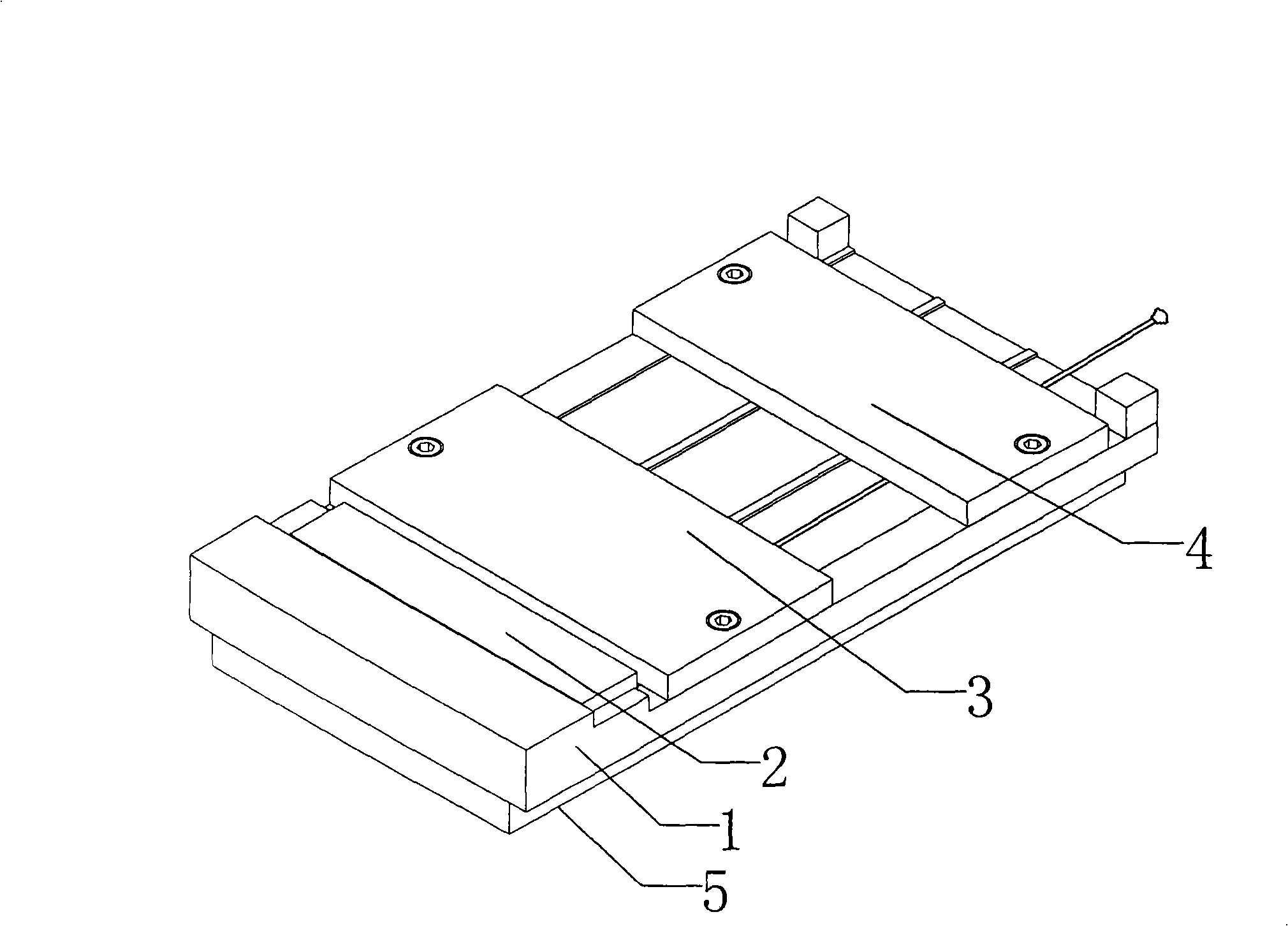

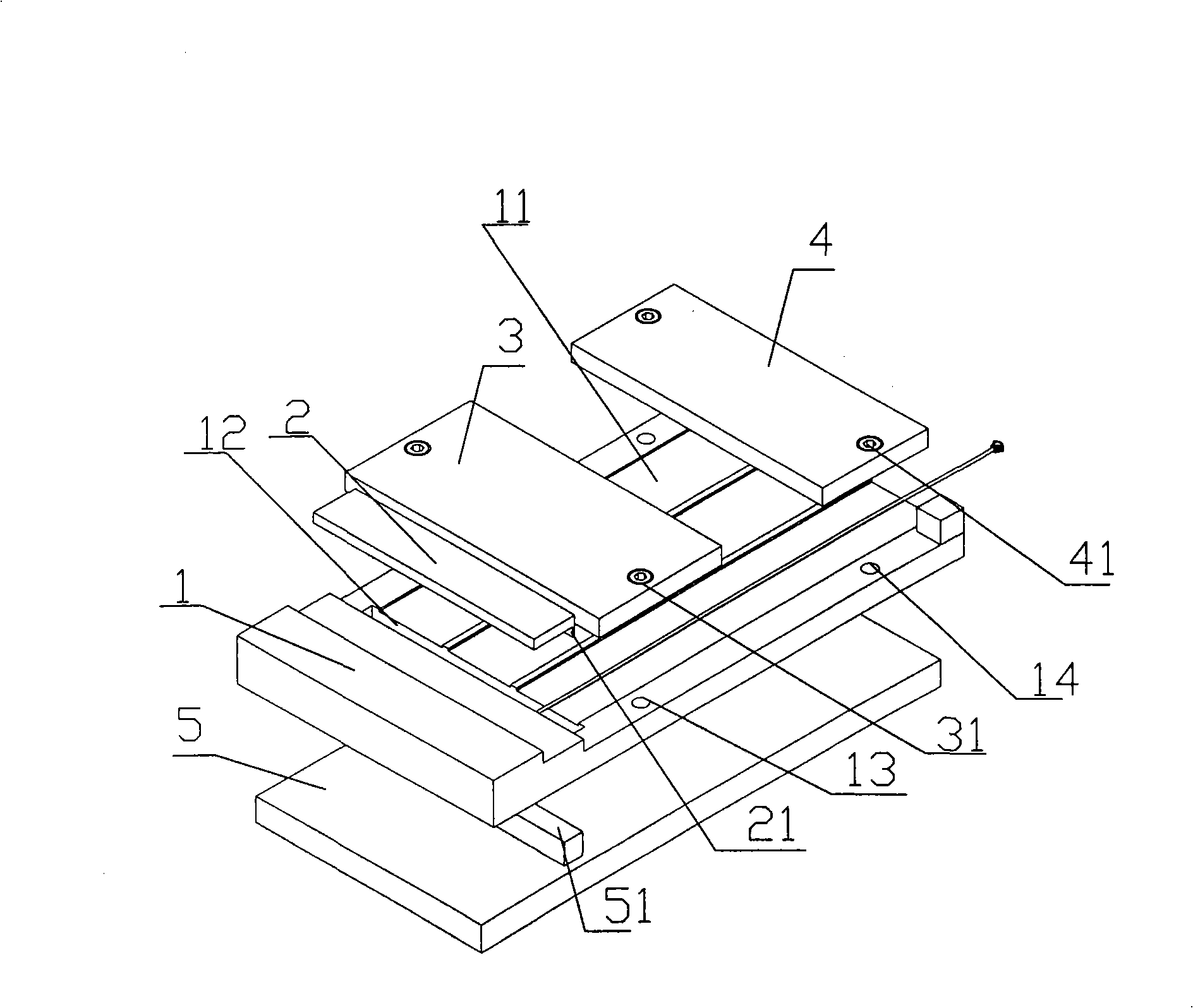

[0024] to combine figure 1 and figure 2 , the following further describes the cable positioning fixture:

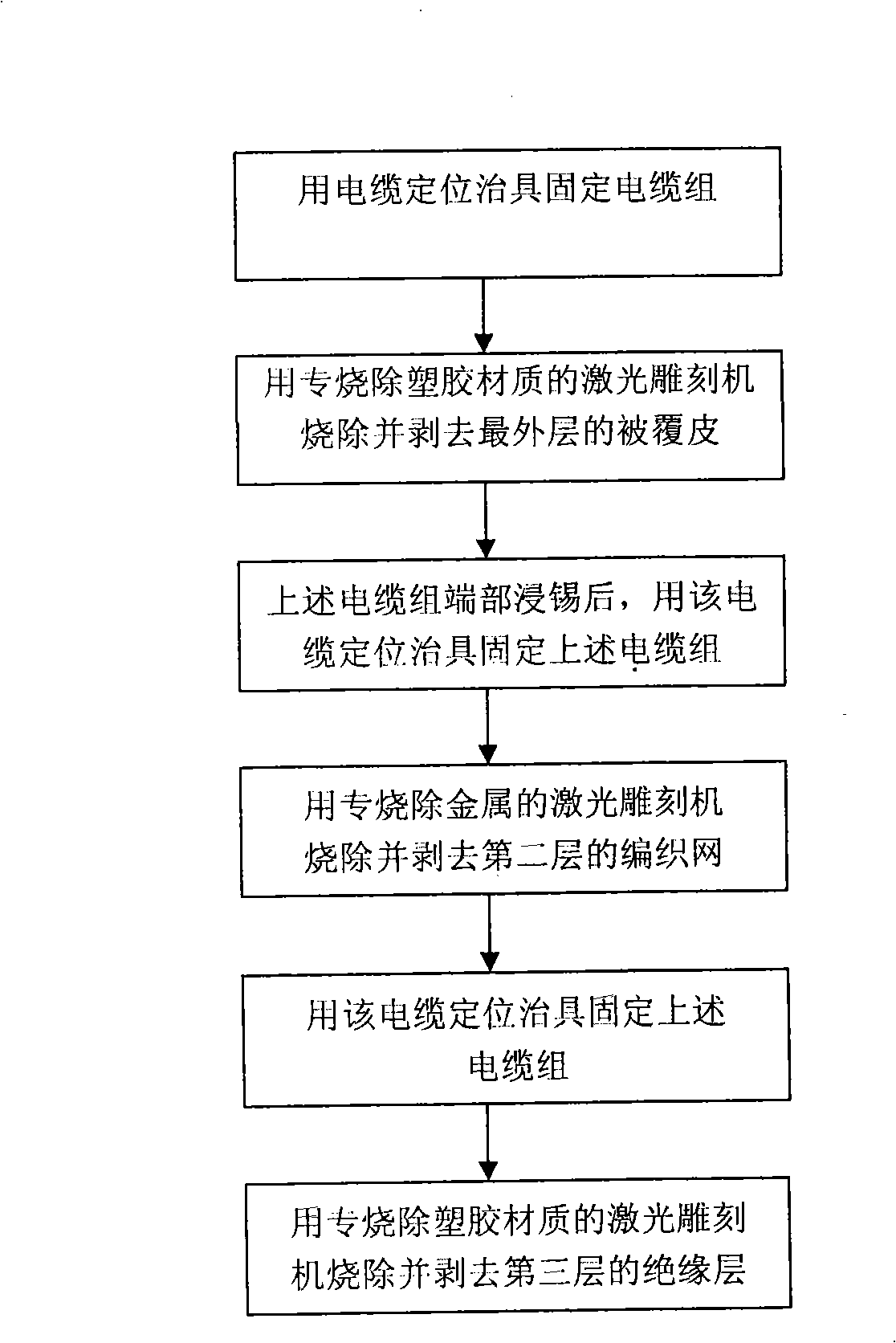

[0025] A cable positioning jig, comprising a base plate 1, a buckle plate 2, a front cover plate 3 and a rear cover plate 4, the base plate is provided with a table 11 on which cable groups can be placed side by side, and the front end of the table is provided with a hole for laser to penetrate the cable group Laser groove 12, the laser groove and the cable group are vertically arranged; the pinch plate 2 is located on the substrate on one side of the laser groove 12, and has a vertical surface 21 that facilitates the alignment of the ends of the cable group; the front cover 3 is located on the laser On the table 11 on the other side of the groove 12, at least a pair of positioning rods 31 and a positioning hole 13 for pressing the head of the cable set are respectively provided between the front cover 3 and the base plate 1 . The front cover can be integrally formed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com