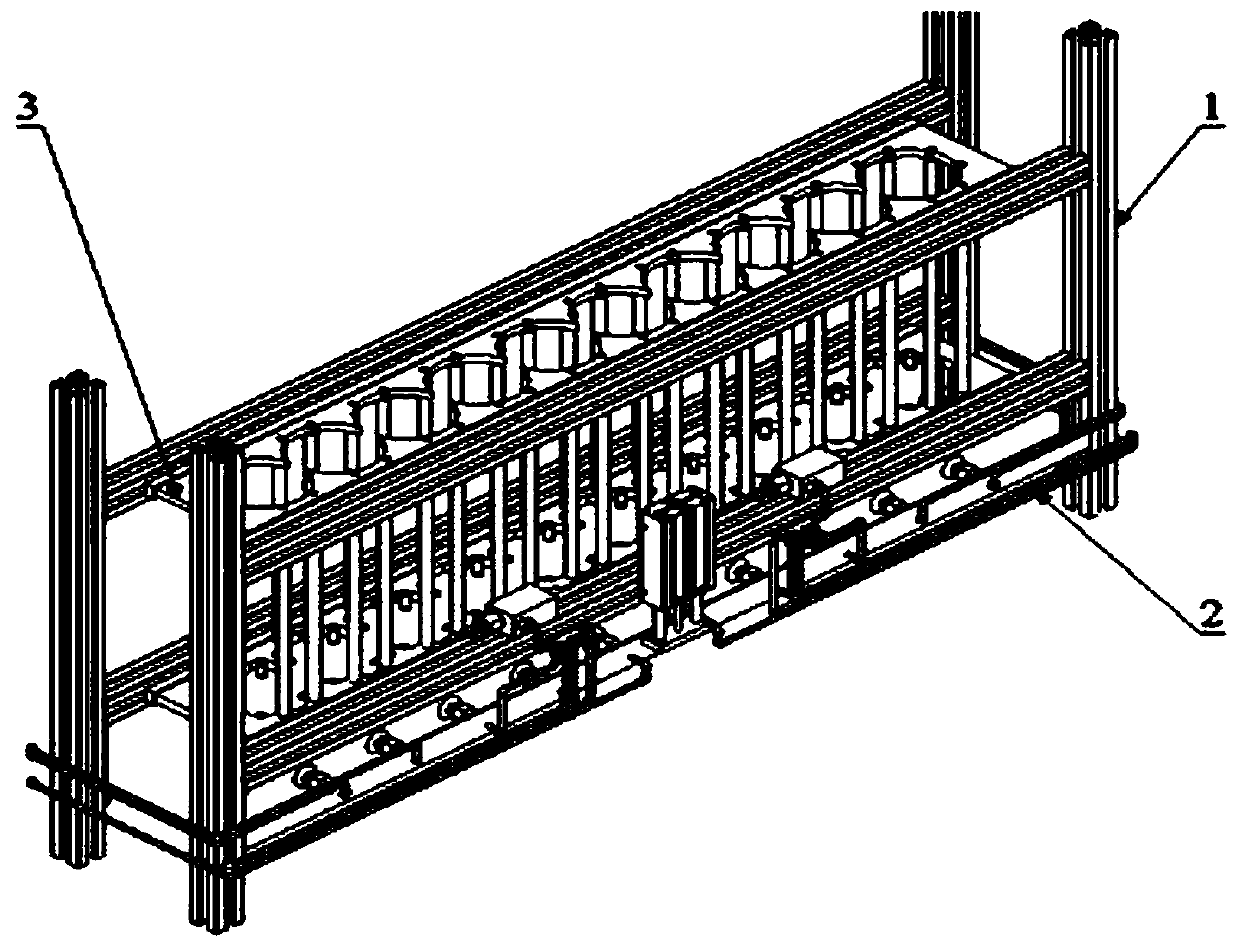

Basin fetching and separating mechanism for full-automatic transplanter for potted flower plug seedlings

A technology for potted flowers and plug seedlings, which is applied in the field of taking and dividing pots, which can solve the problems of large space occupation and falling off of pots and pots, and achieve the effects of reducing occupied space, simple overall structure design, and easy maintenance and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

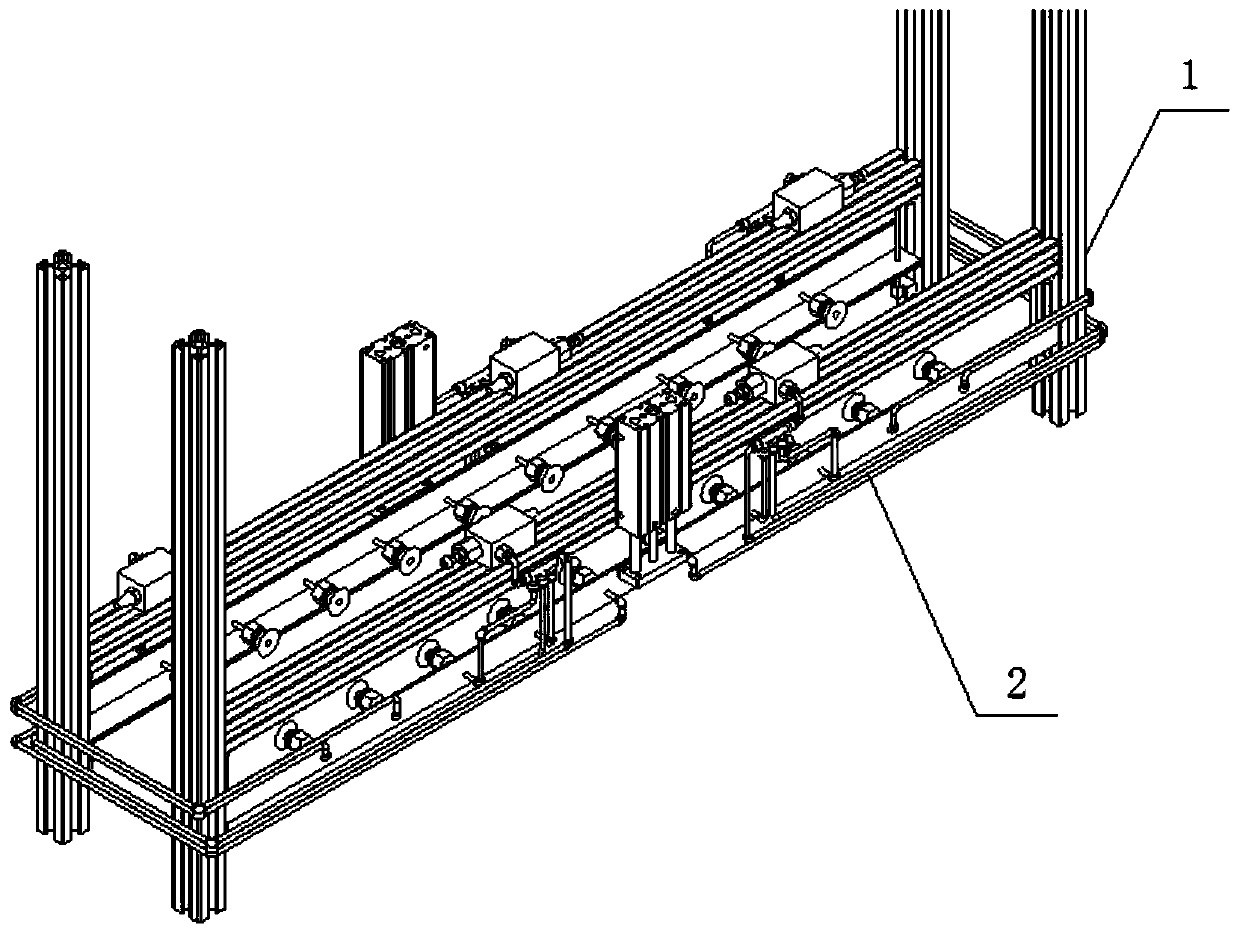

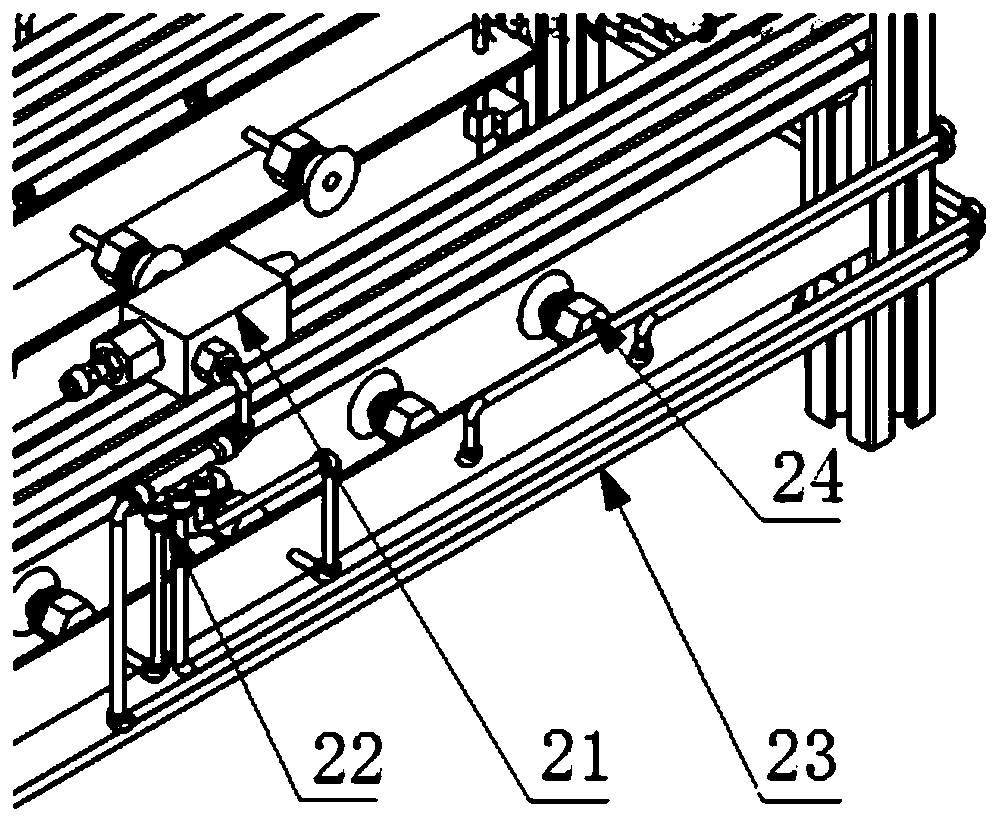

[0031] Such as Figure 1-Figure 7 As shown, a potting and dividing mechanism of a potted flower pot seedling automatic transplanting machine includes a horizontal profile 11, a U-shaped slideway 31 is fixed on the inner side of the horizontal profile 11, and a bottom bowl fixing plate 32 is inserted into the U-shaped slideway 31; the spring plate 33 is inserted into the bottom bowl fixing plate 32 to determine the position of the bowl to be adsorbed for each operation, and the top bowl fixing plate 34 is connected to the bottom bowl fixing plate 32 through a fixed shaft 35; The cylinder 25 is fixed on the center of the lateral profile 11 through the bolt 29, the suction cup fixing plate 26 is connected with the lifting cylinder 25 through a connecting piece, the two ends of the suction cup fixing plate cooperate with the optical axis 27 to fix its position, and the optical axis 27 is inserted into the upper and lower optical axes In the optical axis hole of the support 28, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com