A hydraulic lifting unloading platform and its construction method

A unloading platform, hydraulic technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of high construction costs, poor economic benefits, and inability to recycle, etc., to achieve improved left and right movement, simple operation, Improvement of construction feed efficiency and the effect of repeated utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

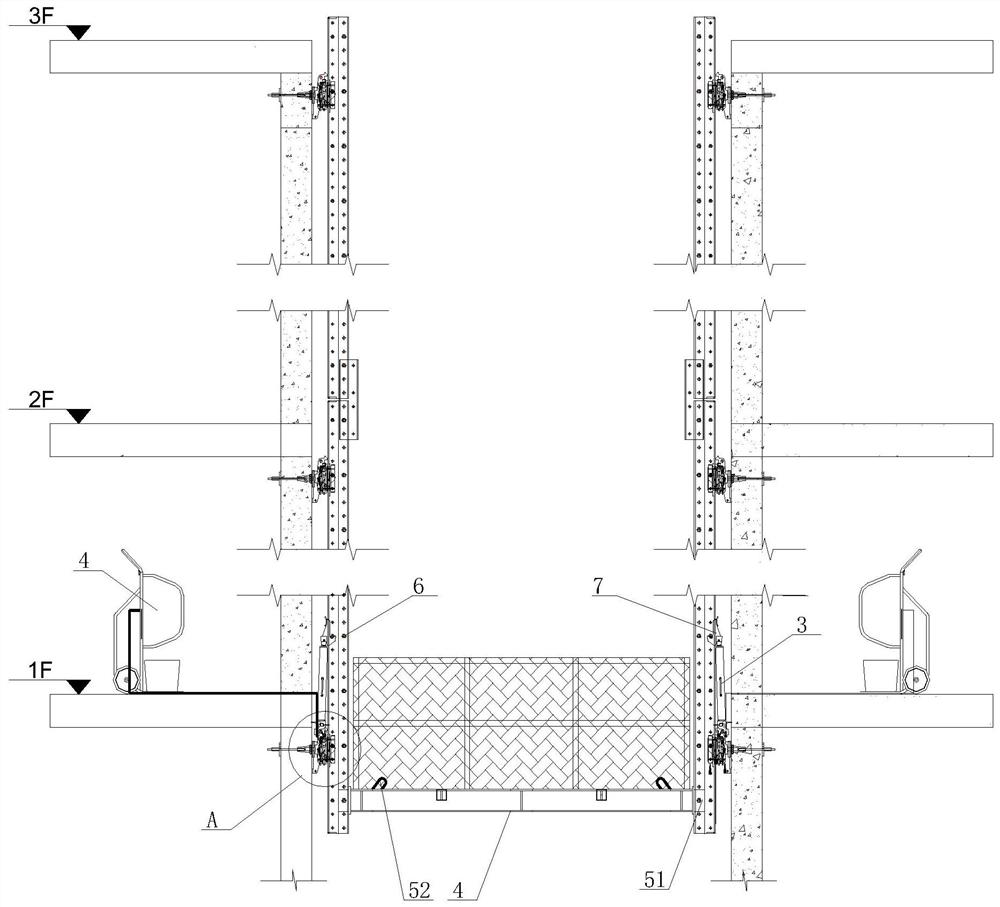

[0037] like Figure 1 to Figure 9 As shown, a hydraulic lifting and unloading platform includes a platform body 5, a climbing guide rail 1, a suspension plate 2, a hydraulic jack 3 and a hydraulic oil pump 4;

[0038] The climbing guide rail 1 is fixedly connected to the side wall of the platform body 5, and there are several jacking support points 6 at equal intervals on the climbing guide rail 1;

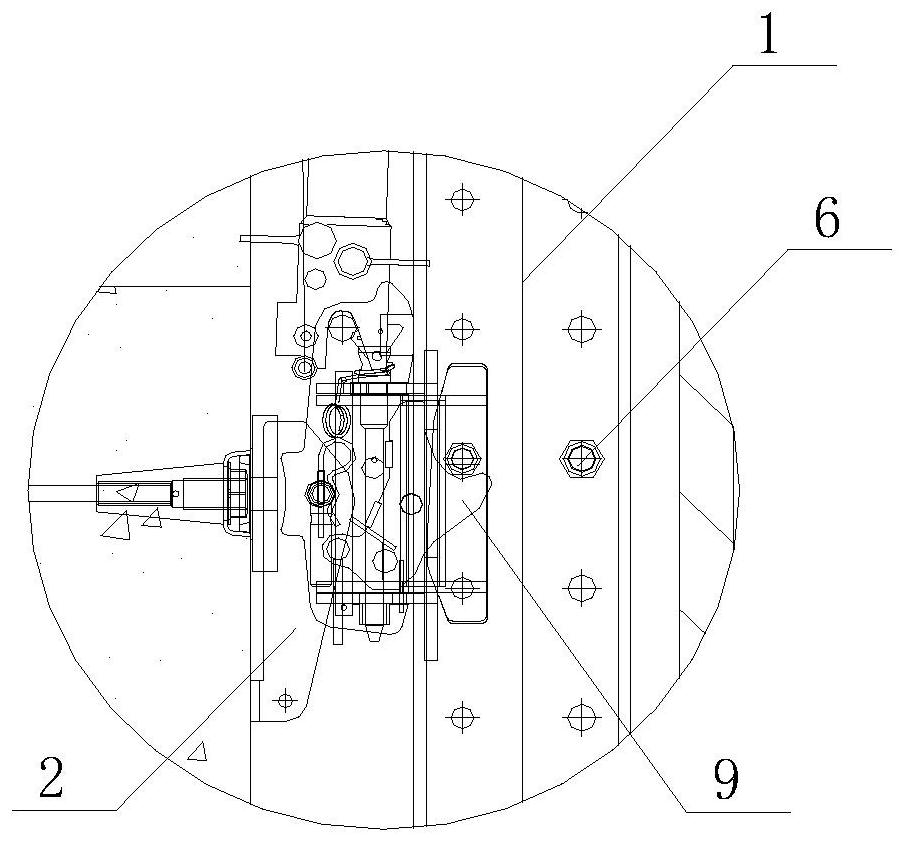

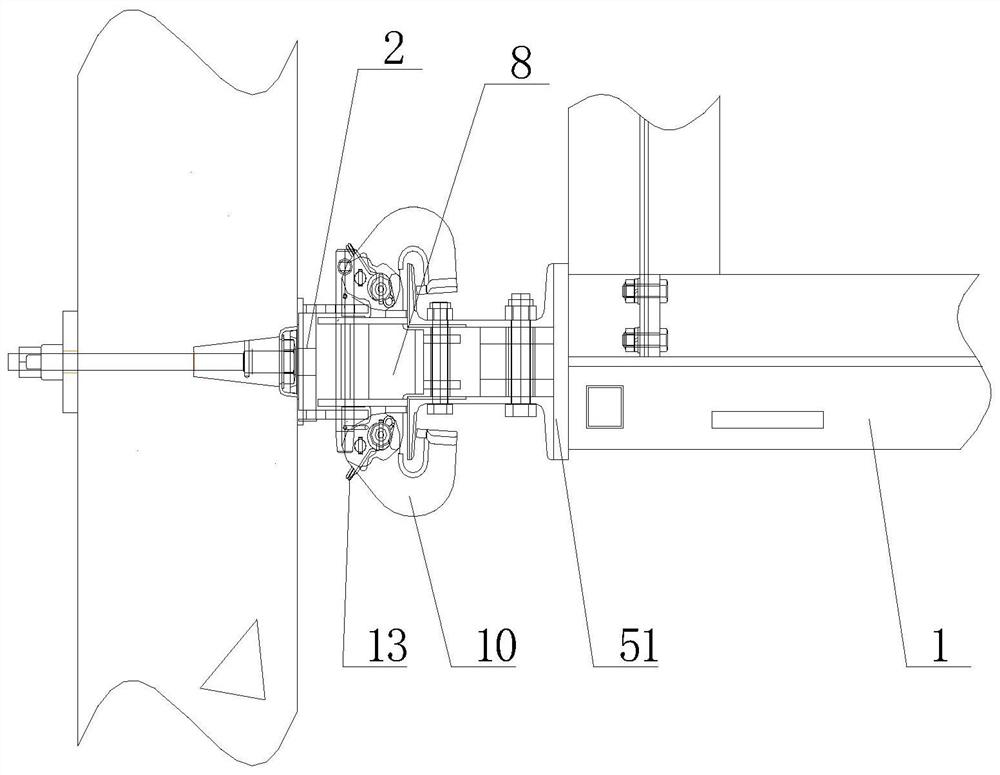

[0039] The suspension plate 2 is fixedly installed on the shear wall through embedded parts, and a locking mechanism is movably connected to the suspension plate 2;

[0040] The fixed end of the hydraulic jack 3 is movably installed on the suspension plate 2, and the output end is movably connected with a jacking piece 7, and the jacking piece 7 is adapted to the jacking support point 6;

[0041] The hydraulic oil pump 4 provides power to the hydraulic jack 3 through the oil pipe.

[0042] The fixed end of the hydraulic jack 3 is installed on the suspension plate 2, the free end...

Embodiment 2

[0051] A construction method for a hydraulic lifting and unloading platform, comprising the following steps:

[0052] After the reinforcement of the shear walls on the S1 and 2F layers is completed, install the embedded parts according to the requirements. When the shear wall concrete reaches a certain strength, remove the shear wall formwork, and fix the hanging plate 2 on the embedded parts. On the hanging plate 2 Install the various components of the locking mechanism, fix the first floor climbing guide rail 1 on the platform body 5, and restrict the front and rear movement of the first floor climbing guide rail 1 through the anti-detachment member 10;

[0053] After the reinforcement of the shear wall on the S2 and 3F layers is completed, install the embedded parts according to the requirements. When the shear wall concrete reaches a certain strength, remove the shear wall formwork, and fix the hanging plate 2 on the embedded parts. On the hanging plate 2 Install the vario...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com