Fuzz fabric hot-air setting machine

A technology of plush fabric and setting machine, which is applied in the direction of fabric surface trimming, heating/cooling fabric, textile and paper making, etc. problems, to achieve the effect of enhancing softness, warmth retention, breathability, and improving visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

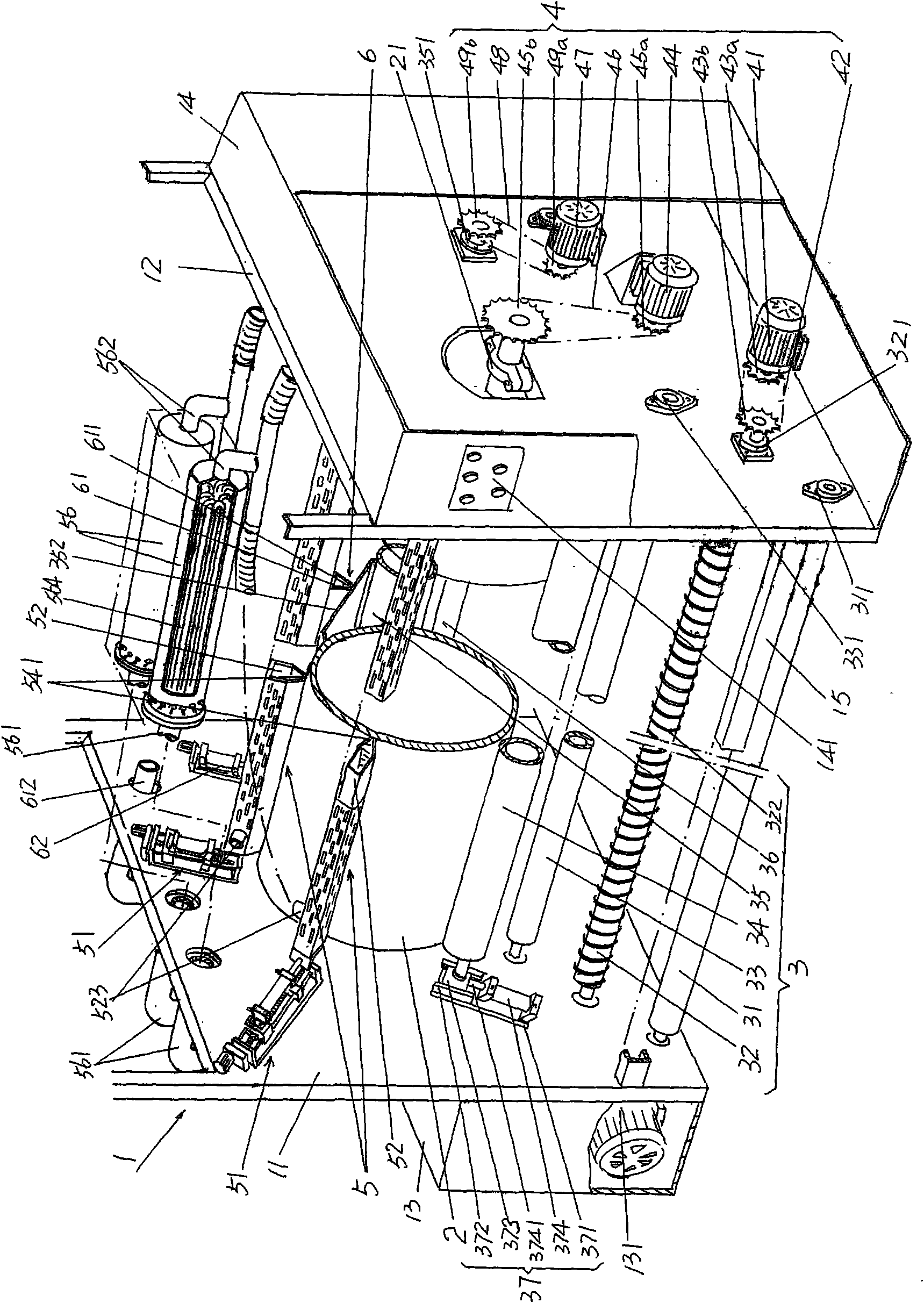

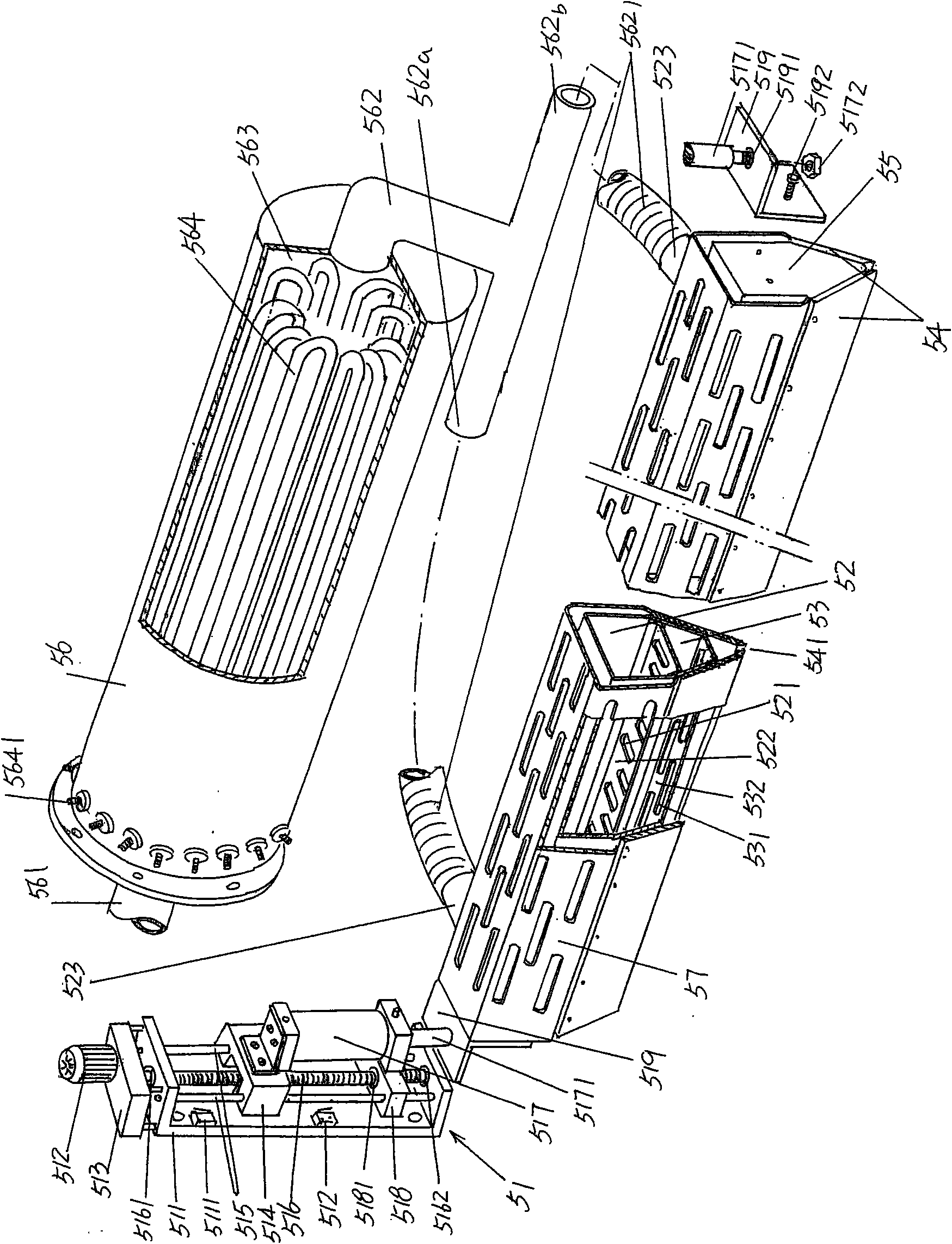

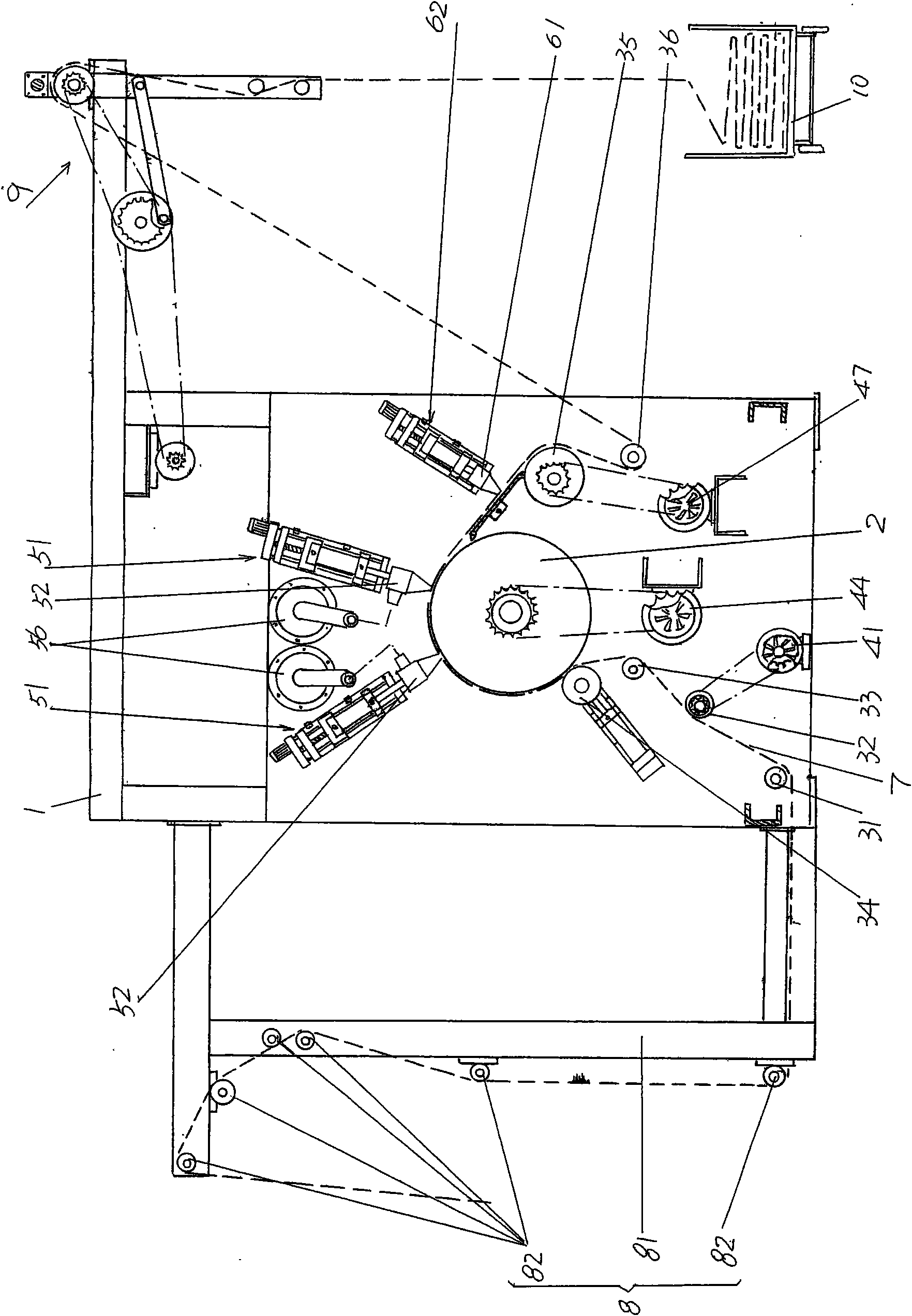

[0022] please see figure 1 , provides a frame 1 composed of left and right wall panels 11, 12 that are arranged in a face-to-face state and connected by a support joint 15 at the bottom. There is bellows 13, fan 131 is arranged in bellows 13, the air inlet place of the shell of bellows 13 is preferably provided with filter screen, so that prevent the fiber dust dust of production place from being sucked by fan 131, the air outlet of fan 131 passes through tee joint or In other similar ways, it is connected with the air heating injection mechanism 5 and the cold air injection mechanism 6 that will be described in detail below. Of course, although the applicant directly combines the bellows 13 on the outer wall of the left wallboard 11 in this embodiment, it is completely possible to present the bellows 13 as being separated from the left wallboard 11, that is, to maintain a certain distance with the left wallboard 11. distance, even the wind box 13 can be arranged in a separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com