Novel crawling pipeline robot

A pipeline robot and robot technology, which is applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of low operation efficiency, poor traction ability, and limit the application of pipeline robots, and achieves improved traction ability and compact structure. , the effect of improving reliability and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

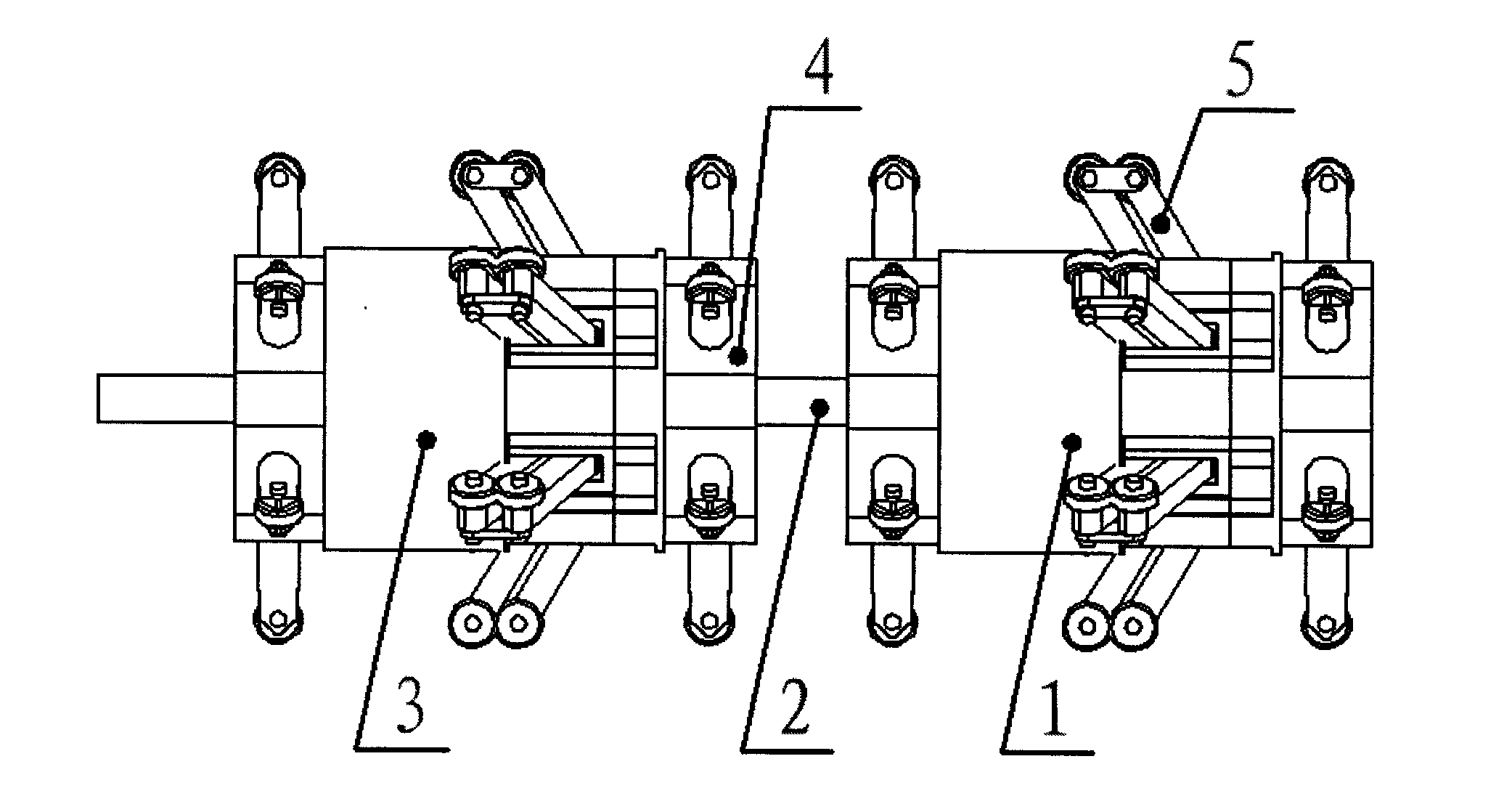

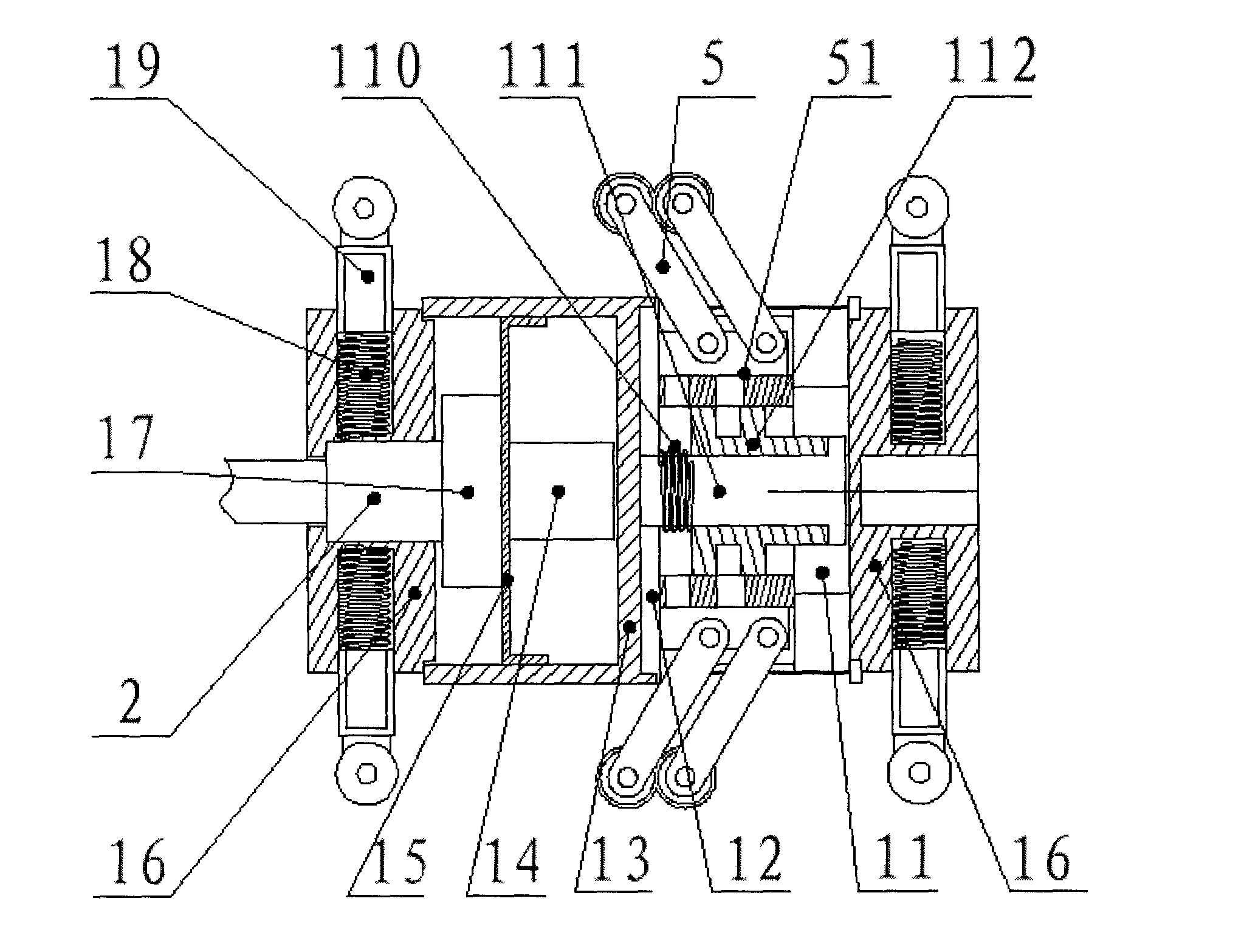

[0030] Such as figure 1 As shown, a new peristaltic pipeline robot includes: a front body 1, a rear body 3, a ball screw 2, a support wheel mechanism 4 and a one-way walking mechanism 5.

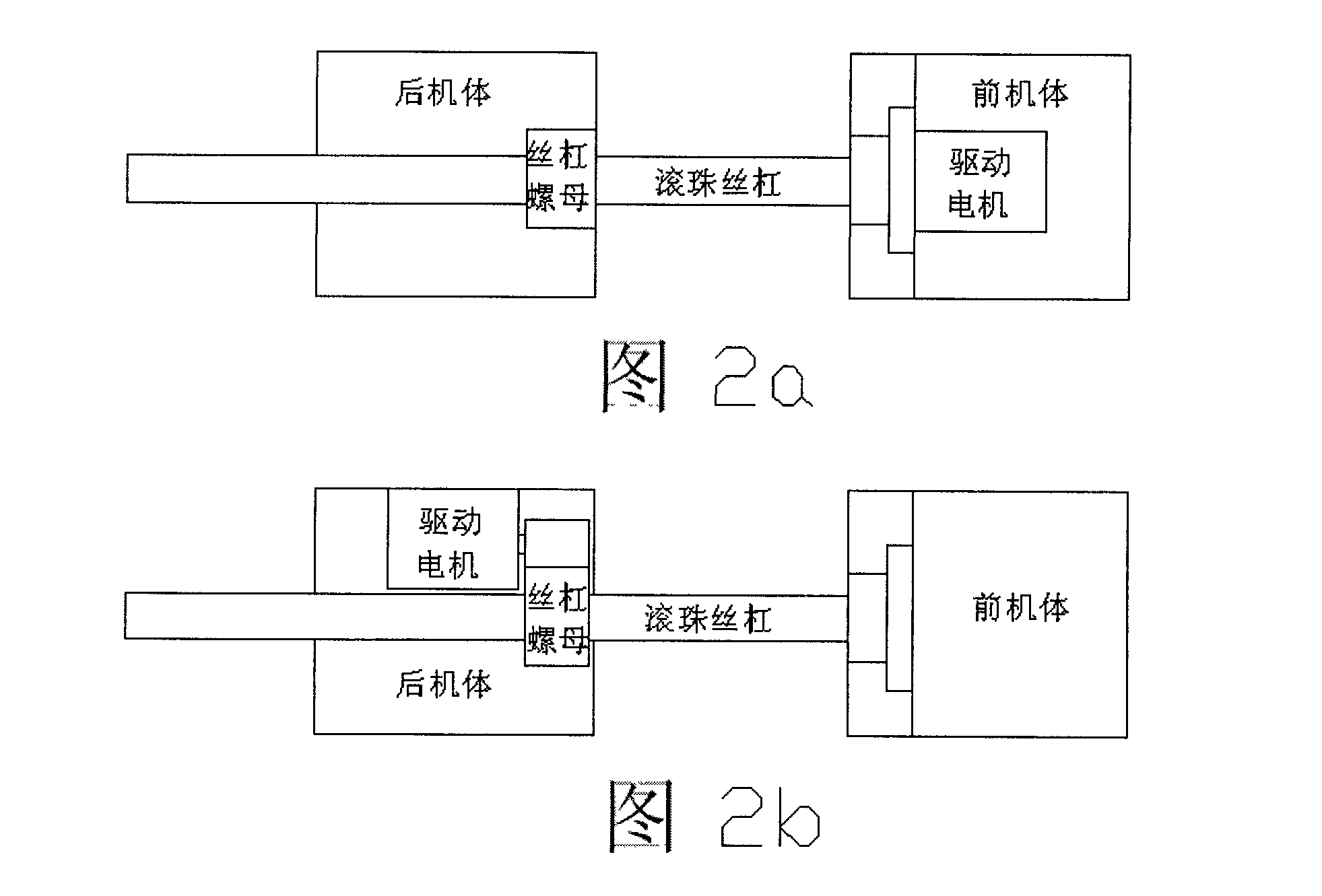

[0031] Such as figure 2 As shown in a, one embodiment of the peristaltic drive mechanism is that the drive motor is installed on the front body, the ball screw is connected to the front body through the drive motor shaft, the screw nut is fixed on the rear body, and the motor drives the ball screw around its own axis. Turn, the screw nut does not move, so that the screw nut drives the rear body to move along the axis of the screw. Such as figure 2 As shown in b, another embodiment of the peristaltic drive mechanism is that the drive motor is installed on the rear body, the ball screw is fixed to the front body through the flange, and the screw nut is installed on the rear body, which can be driven by the drive motor to rotate. If the ball screw remains still, the movement of the screw n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com