Telegraph pole and its mounting and fixing method

A fixing method and technology of utility poles, applied in the direction of building types, buildings, towers, etc., can solve the problems of small supporting area, anti-dumping, ineffective breaking ability, no obvious improvement in anti-dumping ability, etc., and achieve an increase in the force-bearing area Larger, lower installation costs, and avoid accidental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention will be further described, but therefore the present invention is not limited among the scope of described embodiment:

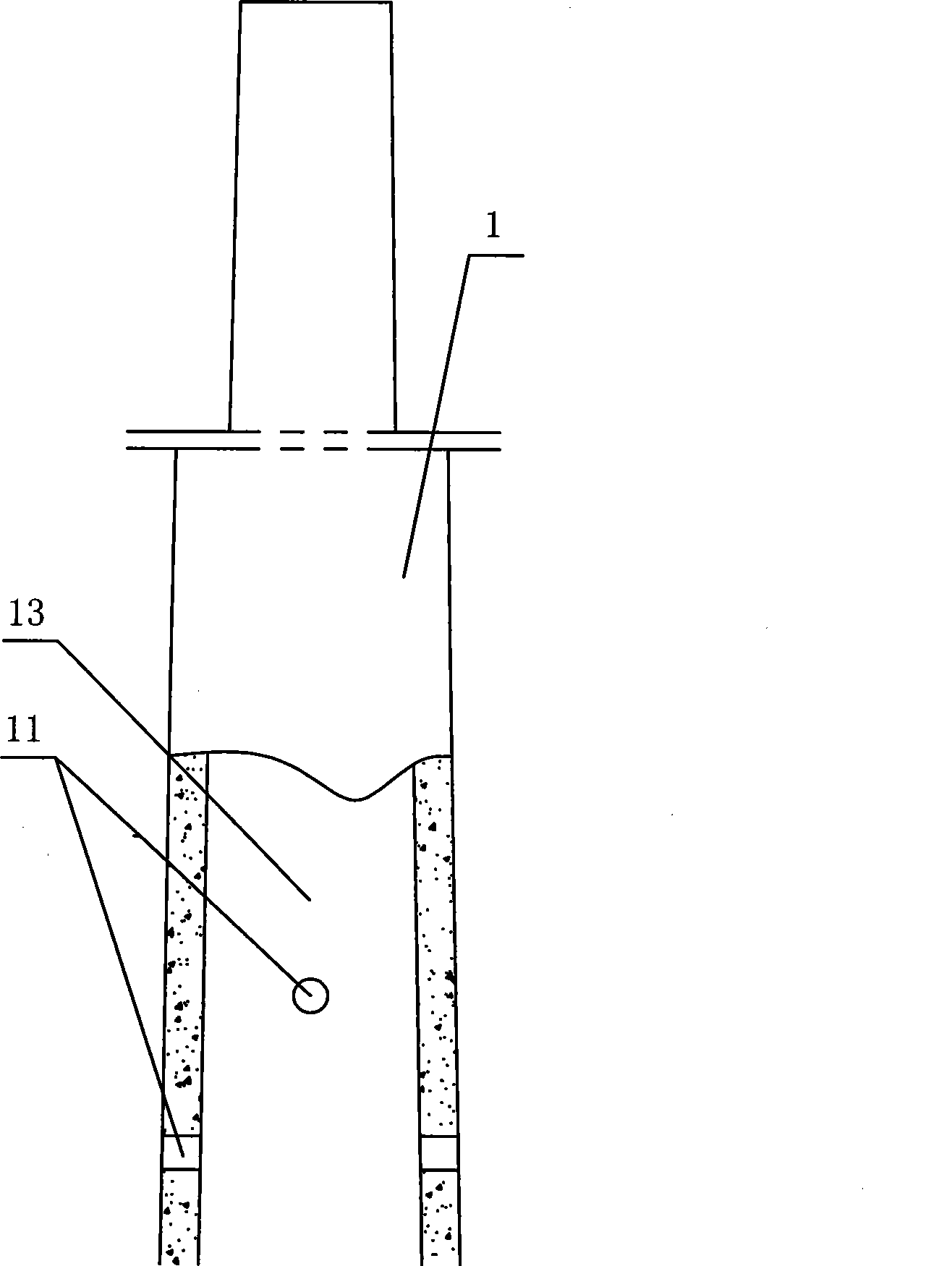

[0028] see figure 1 , a utility pole, comprising a utility pole body 1, the utility pole body 1 is in the shape of a truncated cone from top to bottom, the utility pole body 1 has a cavity 13, and is characterized in that a through hole is provided at the lower end of the utility pole body 1 11. The through hole 11 runs through the utility pole body 1 transversely.

[0029] The installation and fixing method of the above-mentioned utility pole comprises the following steps:

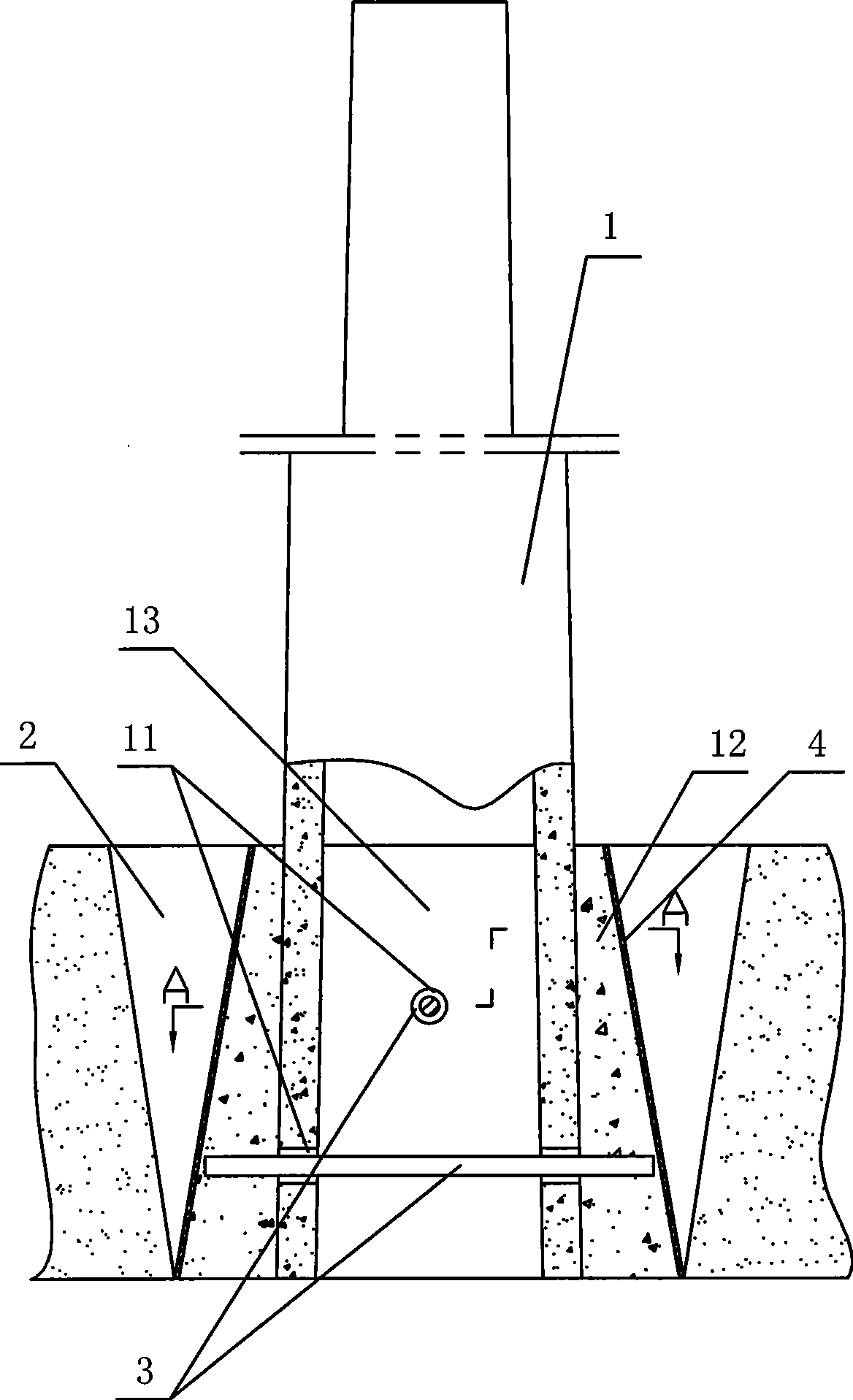

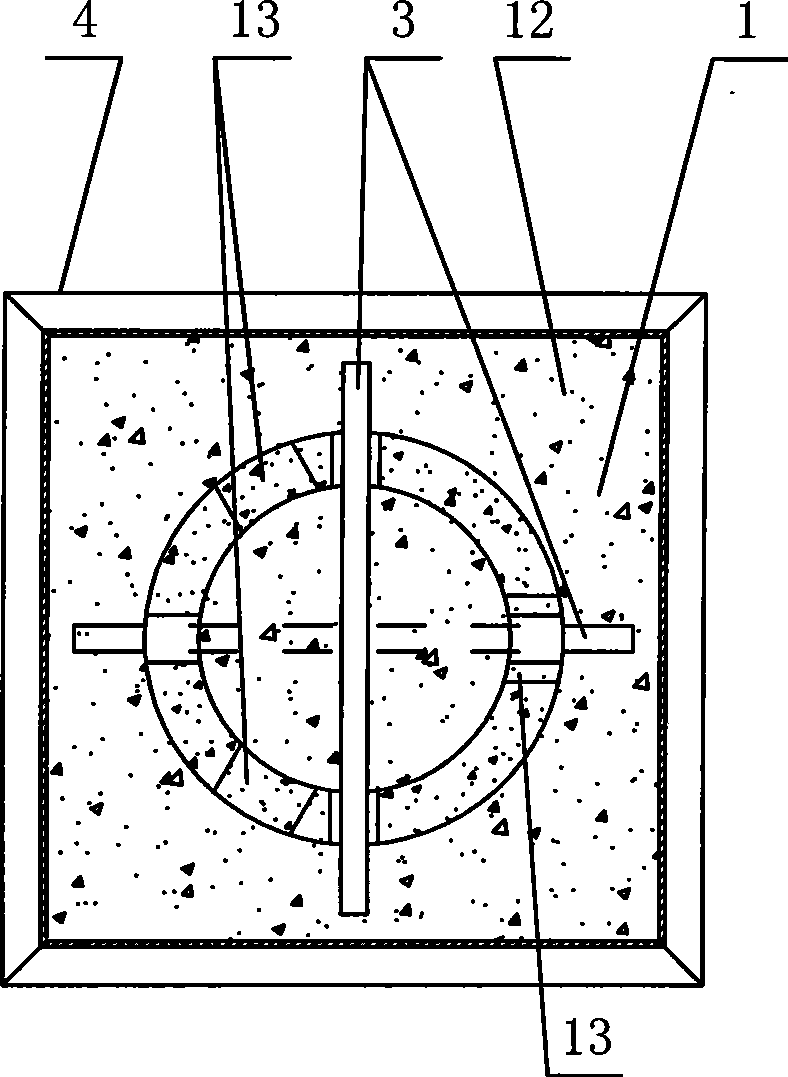

[0030] In this embodiment, the pole body 1 is a reinforced concrete pole with a length of 12m and a diameter of 35cm at the large end; see figure 2 , image 3 , Figure 4 , Figure 5 ;

[0031] I. Make two through holes 11 at the lower end of the utility pole body 1. The diameter runs through the utility...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com