Optical automatic screening machine for springs

An optical automatic and screening machine technology, applied in the field of spring equipment, can solve the problems that the detection accuracy needs to be improved, the automatic screening cannot be realized, and the screening efficiency is low, so as to achieve a high pass rate, improve stability, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

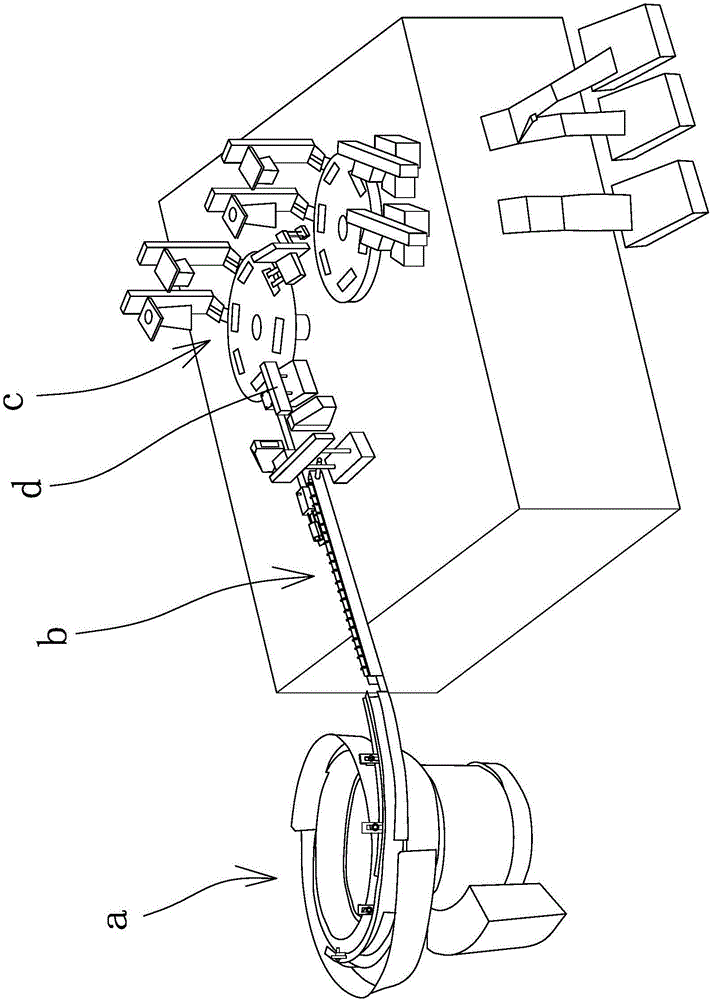

[0027] Such as Figure 1 to Figure 8 As shown, this solution includes a working platform b1, the working platform b1 is provided with a vibrating discharging mechanism a, and the spring output from the discharging end of the vibrating discharging mechanism a is transferred to the detection device c through the conveying mechanism b. The spring is used for detection. The detection device c includes at least one detection mechanism arranged on the working platform b1. The rotating disk c2 is a rotating disk c2, and the detection mechanism also includes at least one optical detection component c3 arranged on the working platform b1. When the rotating disk c2 turns the spring to the detection position, the optical detection component c3 can detect spring mass.

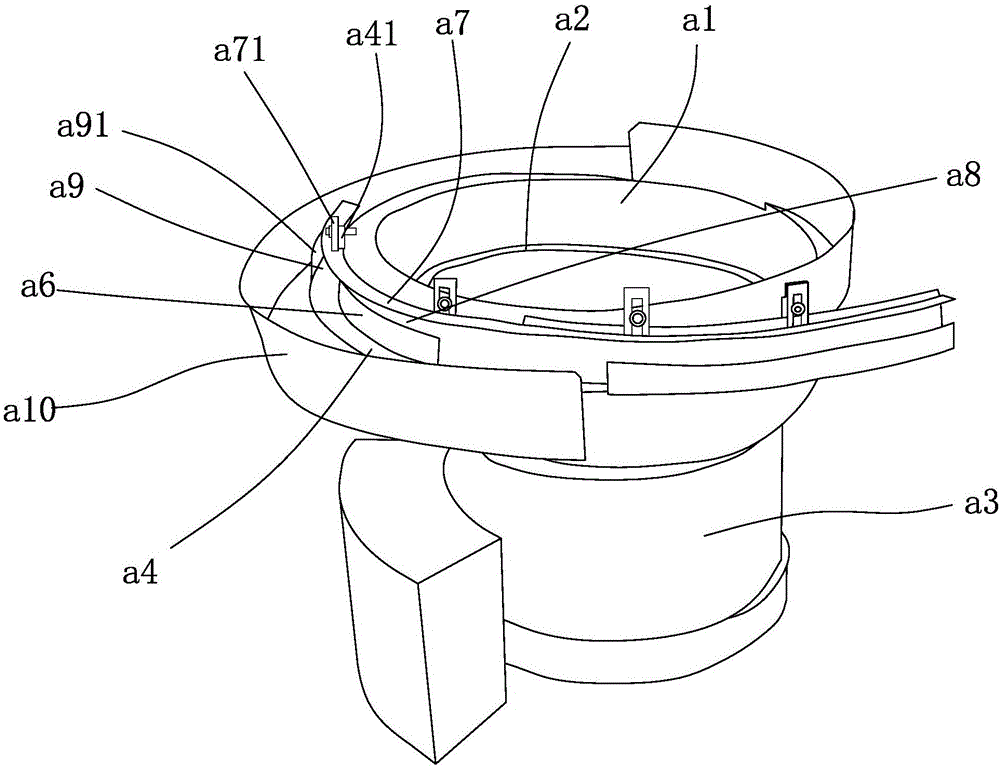

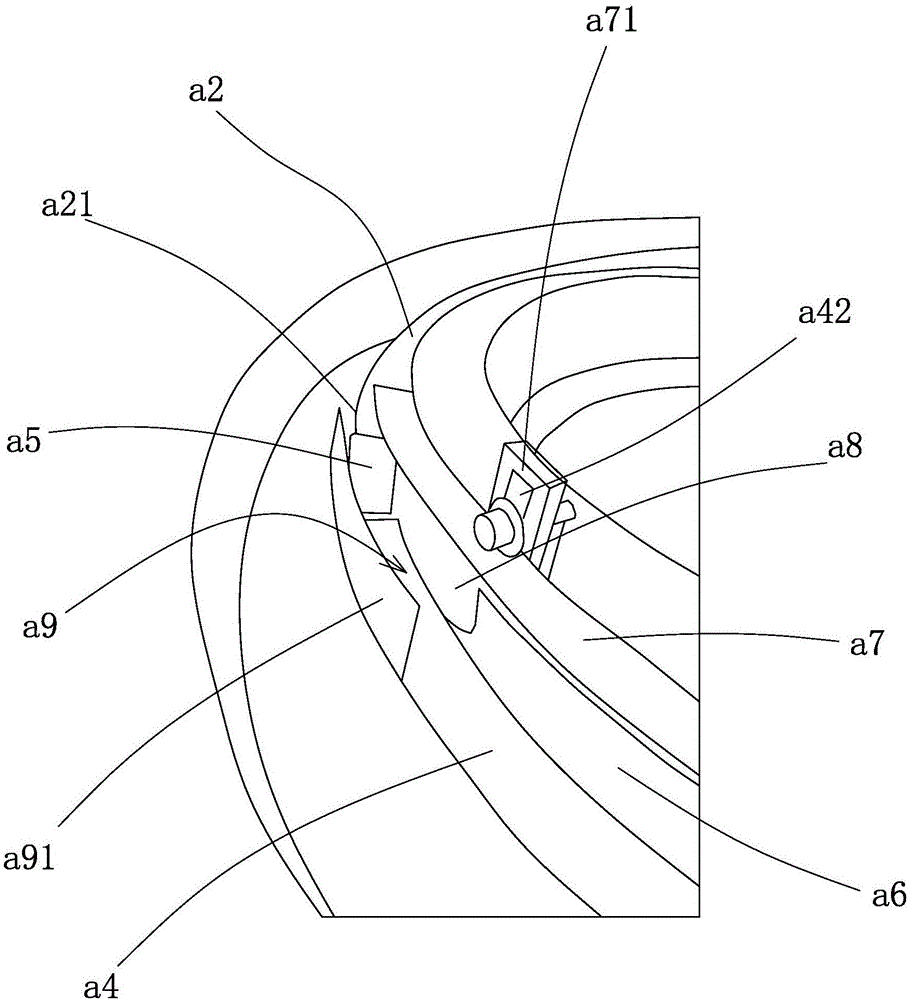

[0028] The vibrating discharge mechanism a in this solution includes a vibrating plate a1, and the vibrating plate a1 is provided with a device capable of driving the vibrating plate a1 to perform torsional vibration so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com