High-stability aquatic product feed granules and preparation method thereof

An aquatic feed, high stability technology, applied in the field of feed, can solve the problems of dissolution and diffusion loss, reduction of effective concentration, pollution of water environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

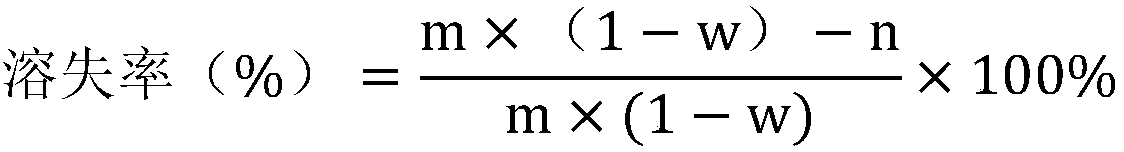

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: A high-stability aquatic feed granule, which includes a feed core layer, a slow-release layer, and a coating layer from the inside to the outside, and the coating layer is composed of acrylic resin and gelatin in a mass ratio of 40:60. The slow-release layer is made of gluten, and the aquatic feed granules are made by the following preparation method:

[0044] (1) Preparation of feed core layer:

[0045] S1. Mix phytase and dialdehyde-based nanocellulose carrier uniformly according to the mass ratio of 1:2, and pass through a 70-mesh sieve to prepare mixture I;

[0046] S2. Sericin was dissolved in 4wt% sodium pyrophosphate aqueous solution to prepare solution II, and the mass ratio of sericin and sodium pyrophosphate aqueous solution was 10:100;

[0047] S3. Mixture I and solution II were processed by a homogenizer to obtain mixture III, and sodium bicarbonate was added, and stirred for 3 minutes to obtain mixture IV. The mass ratio of mixture I and solutio...

Embodiment 2

[0056] Embodiment 2: A kind of high-stability aquatic feed granule, comprises feed core layer, sustained-release layer and coating layer successively from inside to outside, and described coating layer is made of hydroxyethyl cellulose and hydrogenated castor oil according to mass ratio: 60:40, the slow-release layer is made of gluten, and the aquatic feed granules are made by the following preparation method:

[0057] (1) Preparation of feed core layer:

[0058] S1. Mix the Bacillus subtilis and the dialdehyde-based nanocellulose carrier uniformly according to the mass ratio of 1:1, and pass through a 60-mesh sieve to prepare the mixture I;

[0059] S2. Sericin was dissolved in 3 wt % sodium pyrophosphate aqueous solution to prepare solution II, the mass ratio of sericin and sodium pyrophosphate aqueous solution was 50:100;

[0060] S3. Mixture I and solution II were processed by a homogenizer to obtain mixture III, and sodium bicarbonate was added, and stirred for 5 minutes...

Embodiment 3

[0069] Embodiment 3: A kind of high-stability aquatic feed granule, comprises feed core layer, sustained-release layer and coating layer successively from inside to outside, and described coating layer is made of polyethylene glycol 6000 and stearyl alcohol according to mass ratio: 70:30, the slow-release layer is made of gluten, and the aquatic feed granules are made by the following preparation method:

[0070] (1) Preparation of feed core layer:

[0071] S1. Mix betaine and dialdehyde-based nanocellulose carrier uniformly according to the mass ratio of 1:3, and pass through a 60-mesh sieve to prepare mixture I;

[0072] S2. Sericin was dissolved in 3 wt% sodium pyrophosphate aqueous solution to prepare solution II, the mass ratio of sericin and sodium pyrophosphate aqueous solution was 40:100;

[0073] S3. Mixture I and solution II were processed by a homogenizer to obtain mixture III, and sodium bicarbonate was added, and stirred for 3 minutes to obtain mixture IV. The ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com