Apparatus and method for producing sustainable power and heat

a technology of power and heat energy, applied in mechanical apparatus, machines/engines, steam engine plants, etc., to achieve the effect of minimizing power losses and optimizing the conversion of heat energy into electrical power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

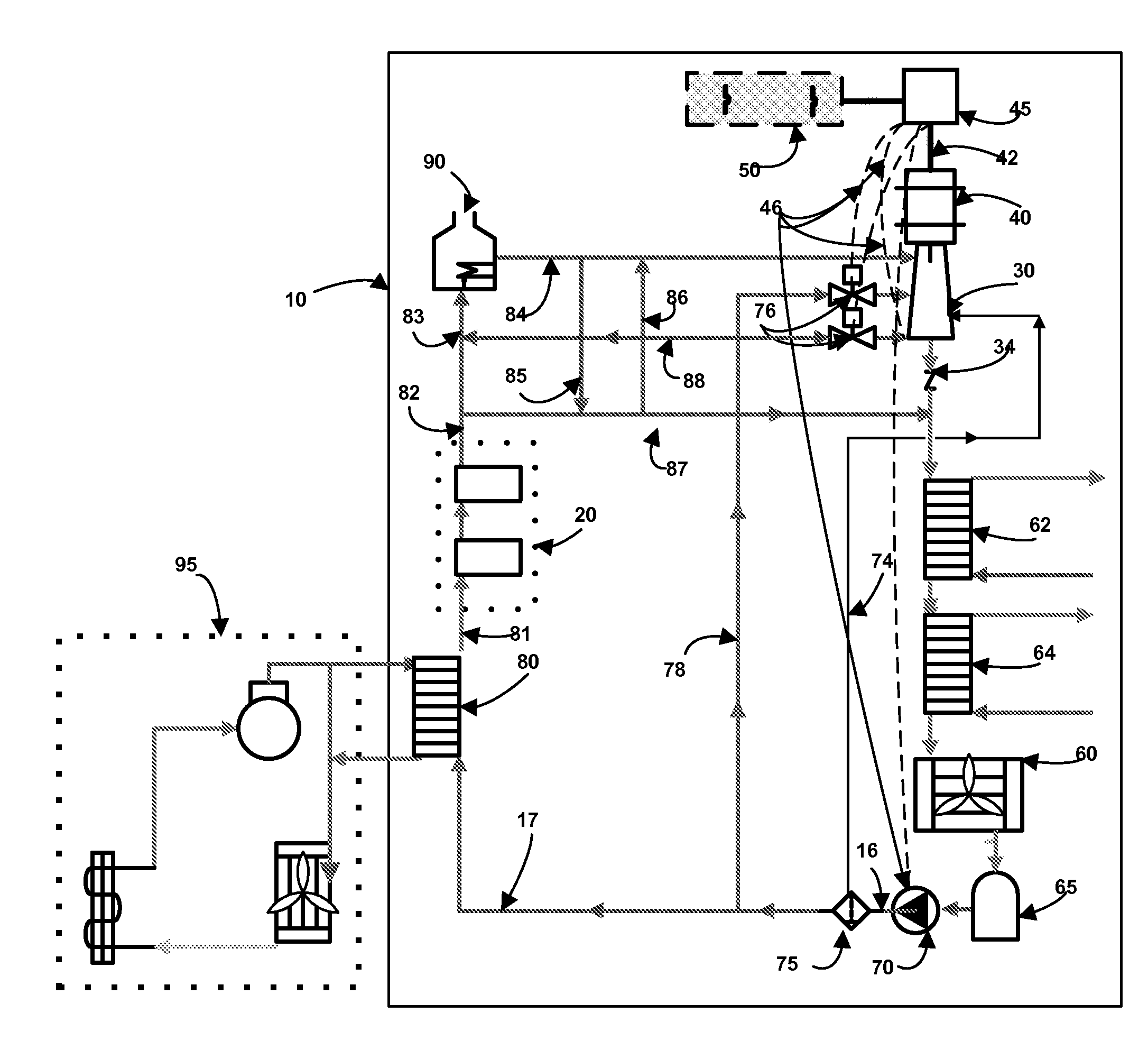

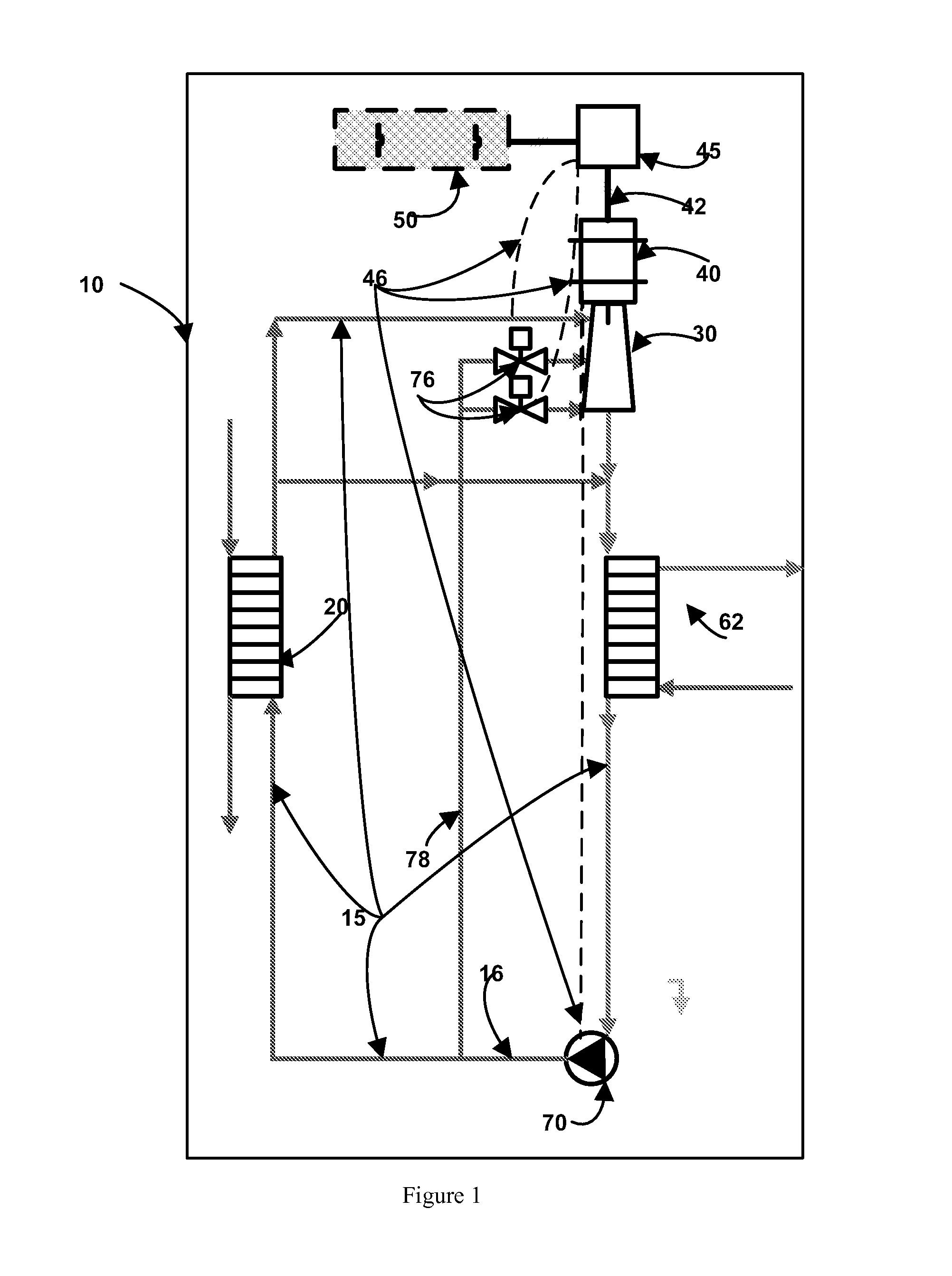

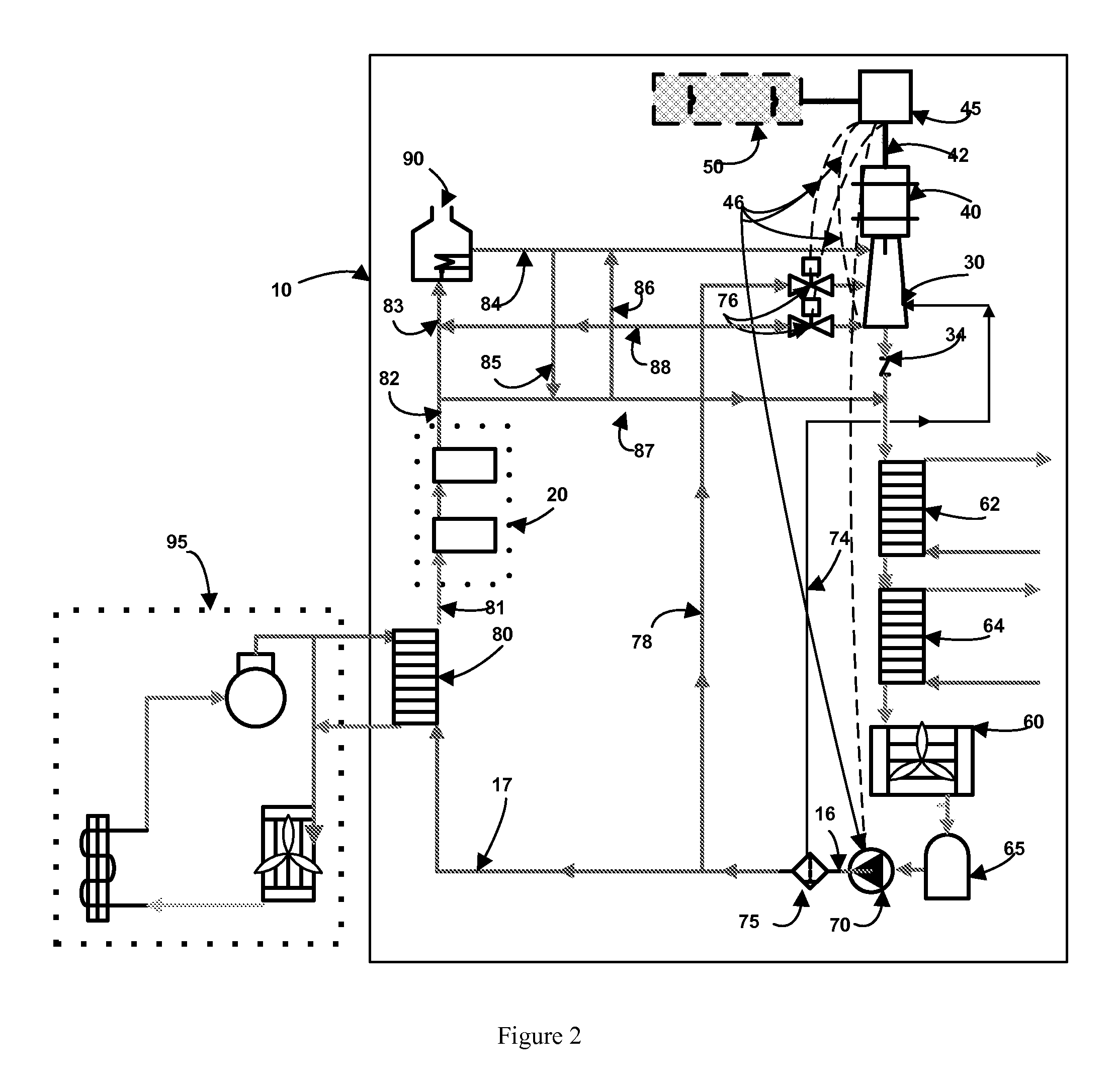

[0031]The present art overcomes the prior art limitations by providing a combined electricity and heat producing system fueled by various sources, primarily solar and other renewable sources integrated with combustion of fossil fuels for a supplemental heat source. With reference to the drawings, FIG. 1 illustrates a possible configuration of the principal hardware components comprising a system embodying the operating mechanisms to affect the benefits described. It is noted however that variations in equipment may be made and would be within the ambit of a person skilled in the art. Referring initially to FIG. 1, one embodiment of the integrated Combined Heat and Power System 10 is a directly-heated, single closed loop system that includes a first (or primary) circuit thermal fluid conduit 15 and a secondary circuit thermal fluid conduit 78. An advantage of the directly heated system is that it eliminates the inherent loss resulting from the pinch points of the various heat sources...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com