High temperature antioxidant for lubricating oil and preparation method thereof

A catalyst and high-boiling-point solvent technology, which is applied in the field of high-temperature antioxidants for lubricating oil and its preparation, can solve problems such as severe sludge and defects in the working range of single amine-type antioxidants, and achieve strong anti-oxidation ability, excellent performance, and work. The time-prolonged effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of high-temperature antioxidant for lubricating oil, specifically: add 30ml of n-decane into a 100ml three-necked reaction bottle, add 3g of diphenylamine and 3.6g of 2,6-di-tert-butylphenol under stirring, , slowly warm up to 140°C, add 8.5ml of di-tert-butyl peroxide dropwise, after the addition, continue to react for 3h, distill off unreacted di-tert-butyl peroxide, cool to room temperature naturally, refrigerate for 30min, and filter with suction , a small amount of n-decane was washed 3 times, dried to obtain 4.8g of the product of Example 1, the appearance of which was light yellow needle-like crystals, and the column chromatography quickly eluted the raw materials to obtain a high-purity compound (developing agent: V 环己烷 :V 二氯甲烷 =20:1) that is, 2,6-di-tert-butyl-4-dianilinophenol, its structural formula is as follows:

[0032] .

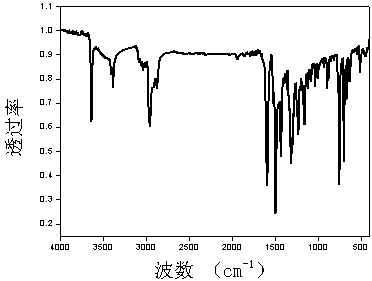

[0033] like figure 1 IR (KBr, vmax) spectrum shows: 3637 cm -1 The left and right sharp peaks are the stre...

Embodiment 2

[0042] A preparation method of high-temperature antioxidant for lubricating oil, specifically: add 30ml of n-decane into a 100ml three-necked reaction bottle, add 3.25g of 3-methyldiphenylamine and 3.6g of 2,6-di-tert-butylphenol under stirring , under the protection of nitrogen atmosphere, slowly raise the temperature to 140°C, add 8.5ml of di-tert-butyl peroxide dropwise, after the addition is complete, continue the reaction for 3h, distill off unreacted di-tert-butyl peroxide, and cool naturally to room temperature. Freeze for 30 minutes, filter with suction, wash with a small amount of n-decane three times, and dry to obtain 5.2 g of light yellow needle-like crystals.

Embodiment 3

[0044] A preparation method of high-temperature antioxidant for lubricating oil, specifically: add 30ml of n-decane into a 100ml three-necked reaction bottle, add 3.5g of 3-methoxydiphenylamine and 3.6g of 2,6-di-tert-butyl under stirring Phenol, under the protection of nitrogen atmosphere, slowly heat up to 140°C, add 8.5ml of di-tert-butyl peroxide dropwise, after the addition is complete, continue to react for 3h, distill off unreacted di-tert-butyl peroxide, and cool naturally to room temperature , frozen for 30 min, suction filtered, washed with a small amount of n-decane three times, and dried to obtain 5.6 g of powdery white solid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com