Non-linear evolution calculating method of zirconium diboride-silicon carbide composite material oxide

A technology of zirconium diboride and composite materials, which is applied in measurement devices, instruments, optical devices, etc., can solve the problems of inability to reflect the phenomenon of multilayer oxide layer structure, the deviation of calculation model from physical reality, deviation from parabolic and linear laws, etc. , to achieve the effect of clear physical meaning, simple calculation method and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

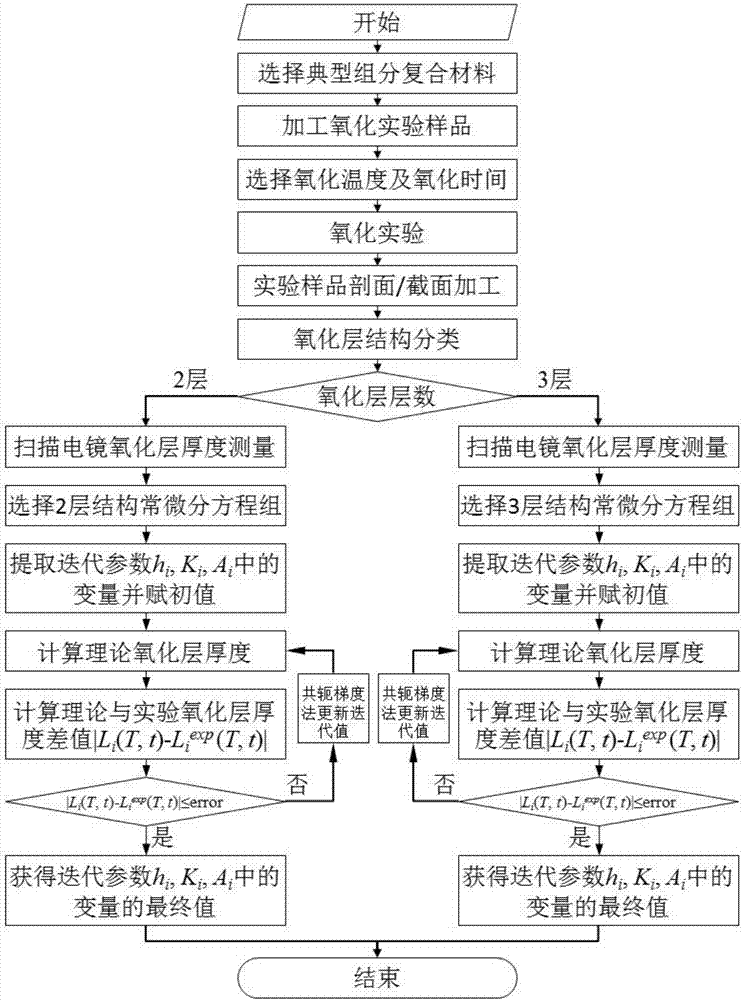

[0035] figure 1 Shown basic analysis flowchart, the concrete implementation process of the present invention is as follows:

[0036] (1) Select ZrB 2 -20vol.% SiC component hot-pressed sintered zirconium diboride-silicon carbide ultra-high temperature ceramic composite material, the sample processing 20 × 10 × 5 (length × width × height) square sheet experimental sample, the experimental sample was placed in In the muffle furnace, set the oxidation temperature to 1700°C and air medium, prepare 9 samples and divide them into 3 groups, and the oxidation holding time of each group is 10 minutes, 30 minutes and 50 minutes respectively;

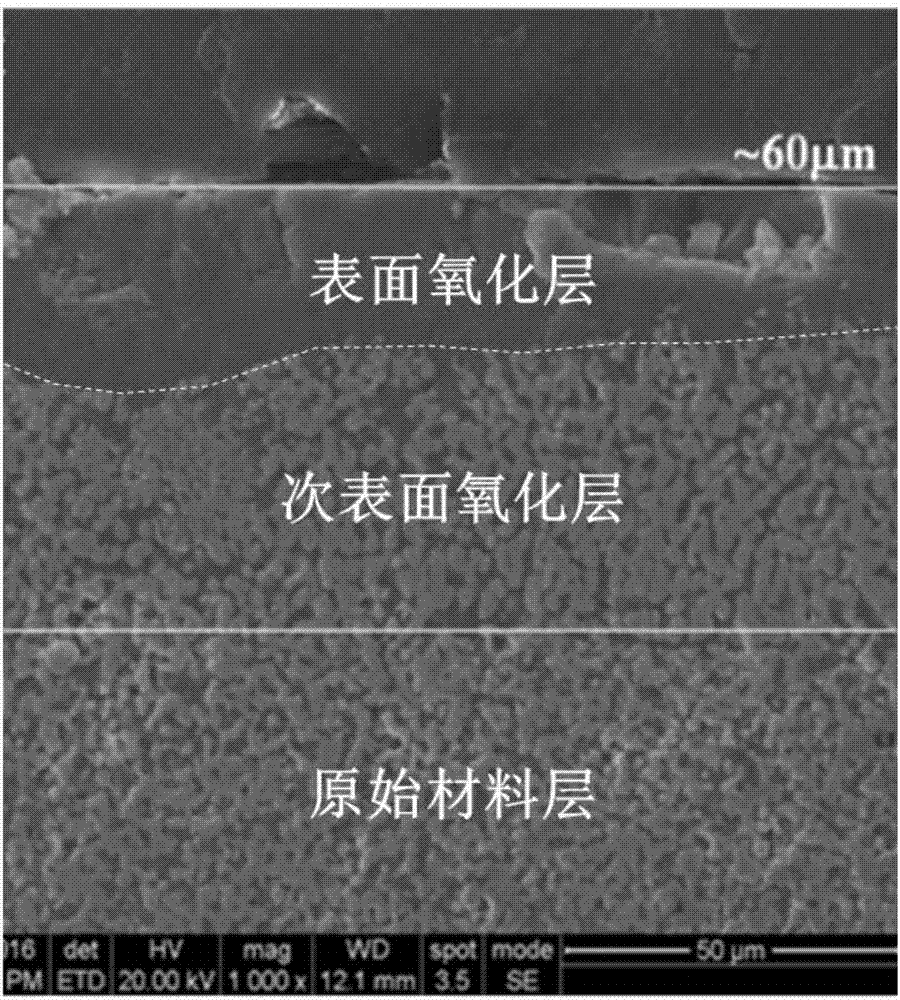

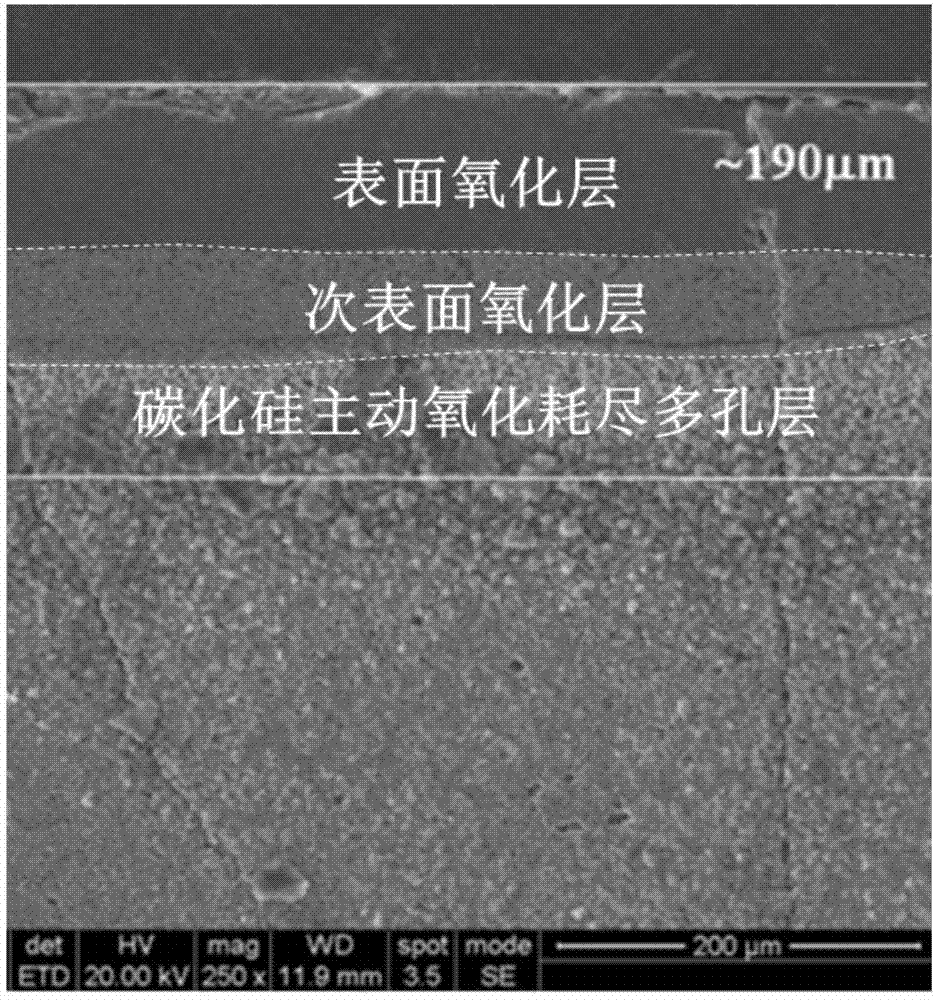

[0037] (2) After the isothermal oxidation experiment is completed, the experimental sample is cooled to room temperature and taken out, and the cross-sectional structure of the oxidized experimental sample is obtained by diamond tool machining or electrical machining, and stored dry to prevent the oxide layer from falling off. Use glue or resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com