Preparation method of high-temperature-resistant, heat-corrosion-resistant and abrasion-resistant coating and penetrating agent

A preparation process and anti-wear technology, which is applied in the direction of metal material coating process, coating, molten spraying, etc., can solve the problems of inability to improve service life, inability to meet TiAl alloy, harsh service conditions, etc., to achieve good performance, Easy to implement, good coating adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

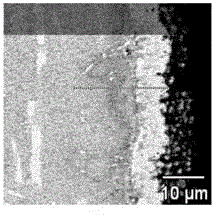

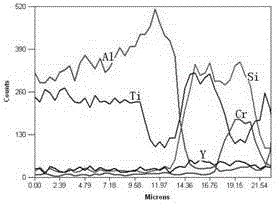

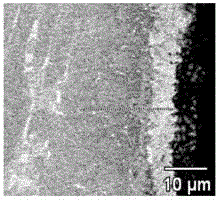

[0054]①Alkali washing: put the TiAl alloy sample in an alkali washing solution with a temperature of 65°C (0.1mol / L sodium hydroxide solution for the alkali washing solution) and soak for 10 minutes; ②Water washing: use the sample after alkali washing Rinse with running water; blow dry; ③ preparation of osmotic agent: accurately weigh the osmotic agent according to the amount, and the proportion of the osmotic agent is by weight percentage: 8% Cr powder, 6% Si powder, 4% Al powder, 8% AlCl 3 powder (analytical pure), 2% Y 2 o 3 powder, and the rest is Al2O3 powder (≤200 mesh); ④Ball milling: Grind the prepared penetrating agent in a ball mill to make it fully mixed, and refine the penetrating agent particles to no more than 200 mesh; The infiltrating agent after ball milling is placed in an oven at 100°C for 1 hour and dried; ⑥ Embedding: put the dried infiltrating agent into a corundum crucible, embed the sample in the infiltrating agent, and make the adjacent Keep a certai...

Embodiment 2

[0056] ①Alkali cleaning: put the TiAl alloy test sample in an alkali washing solution with a temperature of 65°C (0.1-0.2mol / L sodium hydroxide solution for the alkali washing solution) and soak for 10 minutes; ②Water washing: Wash the Rinse the sample with flowing water; dry it; ③ Prepare the osmotic agent: accurately weigh the osmotic agent according to the amount, and the proportion of the osmotic agent is as follows: 8% Cr powder, 6% Si powder, 4% Al powder, 8% AlCl 3 powder (analytical pure), 2% Y 2 o 3 powder, and the rest is Al2O3 powder (≤200 mesh); ④Ball milling: Grind the prepared penetrating agent in a ball mill to make it fully mixed, and refine the penetrating agent particles to no more than 200 mesh; The infiltrating agent after ball milling is placed in an oven at 100°C for 1 hour and dried; ⑥ Embedding: put the dried infiltrating agent into a corundum crucible, and embed the sample in the infiltrating agent. Keep a certain distance between them (≥5cm), ⑦Seal...

Embodiment 3

[0058] ①Alkali cleaning: put the TiAl alloy test sample in an alkali washing solution with a temperature of 65°C (0.1-0.2mol / L sodium hydroxide solution for the alkali washing solution) and soak for 10 minutes; ②Water washing: Wash the Rinse the sample with flowing water; dry it; ③ Prepare the osmotic agent: accurately weigh the osmotic agent according to the amount, and the proportion of the osmotic agent is as follows: 8% Cr powder, 6% Si powder, 4% Al powder, 8% AlCl 3 powder (analytical pure), 2% Y 2 o 3 powder, and the rest is Al2O3 powder (≤200 mesh); ④Ball milling: Grind the prepared penetrating agent in a ball mill to make it fully mixed, and refine the penetrating agent particles to no more than 200 mesh; The infiltrating agent after ball milling is placed in an oven at 100°C for 1 hour and dried; ⑥ Embedding: put the dried infiltrating agent into a corundum crucible, and embed the sample in the infiltrating agent. Keep a certain distance between them (≥5cm), ⑦Seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com