Test method of oxidation stability of transformer oil

A technology for oxidation stability and transformer oil, applied in color/spectral characteristic measurement, instruments, measuring devices, etc., which can solve problems such as long test time, serious accidents, and complex determination of sediment and acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] (1) Using the spectrophotometric measurement method stipulated in the first part of the National Standard GB / T 7602.1-2008 "Determination of T501 Antioxidant Content in Transformer Oil and Turbine Oil" to measure the antioxidant contained in the entrusted transformer oil sample The mass percent concentration;

[0014] (2) Take 20g of entrusted transformer oil samples and place them at an ambient temperature of 100°C, add filamentous red copper as a catalyst, and add oxygen at the same time, and carry out an accelerated oxidation test for 2 hours. The mass ratio of the catalyst red copper to the entrusted transformer oil samples is in order is 0.1:100, and the flow rate of the oxygen is 10ml·min -1 ;

[0015] (3), use the measuring method that above-mentioned step (1) uses to measure the mass percentage concentration of antioxidant in the entrusted transformer oil sample that above-mentioned step (2) obtains through accelerated oxidation test;

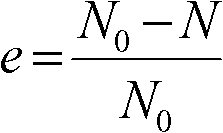

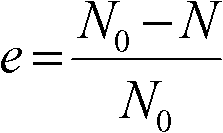

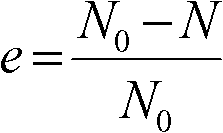

[0016] (4) According to...

Embodiment 2

[0020] (1) Use the infrared spectroscopy measurement method specified in the third part of the national standard GB / T 7602.3-2008 "Determination of T501 Antioxidant Content in Transformer Oil and Turbine Oil" to measure the anti-oxidant contained in the entrusted transformer oil sample. The mass percentage concentration of oxidizing agent;

[0021] (2), take 30g of entrusted transformer oil samples and place them at an ambient temperature of 199°C, add powdery red copper as a catalyst, add oxygen at the same time, and carry out an accelerated oxidation test for 2 hours, the mass ratio of the catalyst red copper to the entrusted transformer oil samples is in order 100:100, the flow rate of the oxygen is 1000ml·min -1 ;

[0022] Steps (3)-(4) are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com