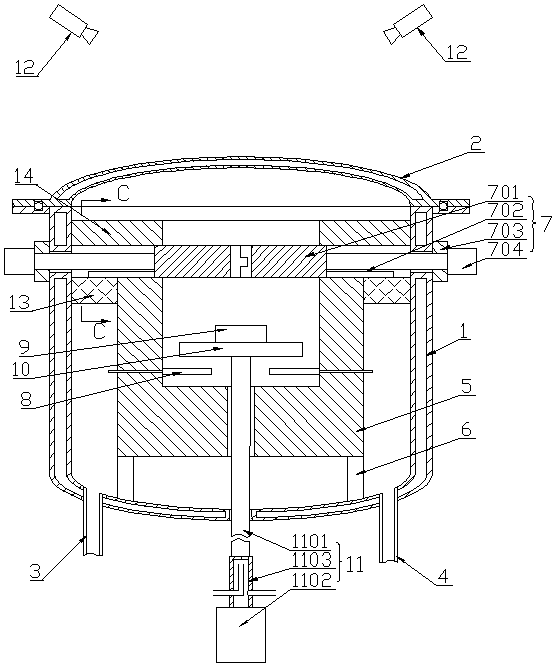

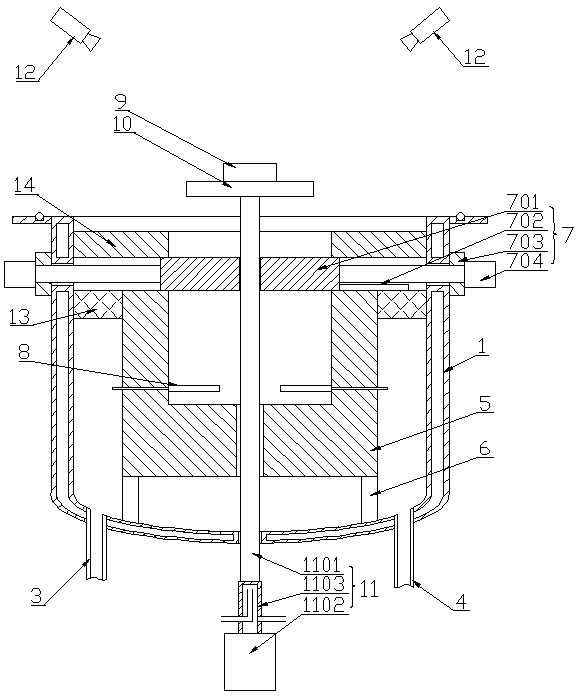

Superhigh temperature oxidation resistance testing platform and testing method

A technology of anti-oxidation performance and test platform, which is applied in measuring devices, material analysis by optical means, instruments, etc., can solve problems such as increasing test cost and impact, and achieve the effect of reducing test cost, improving lifespan and improving market value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

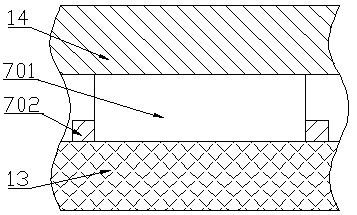

Method used

Image

Examples

specific Embodiment 1

[0034] The ultra-high temperature oxidation resistance test method of the present invention comprises the following steps:

[0035] 1) Prepare the thermal imager and industrial camera, make them in working condition, prepare the computer, and start the imaging analysis software system;

[0036] 2) According to the test requirements, heat directly in an oxidizing atmosphere, heat the temperature in the furnace to 1000°C, and then stop heating;

[0037] 3) Quickly open the furnace door and insulation door;

[0038] 4) Quickly raise the tested sample:

[0039] 5) Quickly close the insulation door;

[0040] 6) Use a thermal imager to observe the dynamic change of the surface temperature of the sample; the industrial camera detects the change of the sample with temperature and time, and the change of material shape; and make a dynamic model through the software system for further detection and analysis of the sample over time, Changes in temperature, changes in the sample.

specific Embodiment 2

[0042] The ultra-high temperature oxidation resistance test method of the present invention comprises the following steps:

[0043]1) Prepare the thermal imager and industrial camera, make them in working condition, prepare the computer, and start the imaging analysis software system;

[0044] 2) According to the test requirements, vacuumize the furnace body to 10-1000Pa, heat the temperature in the furnace to 2000°C, and then stop heating;

[0045] 3) Quickly open the furnace door and insulation door;

[0046] 4) Quickly raise the tested sample:

[0047] 5) Quickly close the insulation door;

[0048] 6) Use a thermal imager to observe the dynamic change of the surface temperature of the sample; the industrial camera detects the change of the sample with temperature and time, and the change of material shape; and make a dynamic model through the software system for further detection and analysis of the sample over time, Changes in temperature, changes in the sample.

specific Embodiment 3

[0050] The ultra-high temperature oxidation resistance test method of the present invention comprises the following steps:

[0051] 1) Prepare the thermal imager and industrial camera, make them in working condition, prepare the computer, and start the imaging analysis software system;

[0052] 2) According to the test requirements, vacuumize the furnace body to 10-1000Pa, then fill in protective gas to make the pressure in the furnace reach 0.101-0.15MPa, heat the temperature in the furnace to 2500°C, and then stop heating;

[0053] 3) Quickly open the furnace door and insulation door;

[0054] 4) Quickly raise the tested sample:

[0055] 5) Close the insulation door quickly to prevent excessive oxidizing atmosphere from entering the furnace;

[0056] 6) Use a thermal imager to observe the dynamic change of the surface temperature of the sample; the industrial camera detects the change of the sample with temperature and time, and the change of material shape; and make a dyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com