Wind turbine with friction drive power take off on outer rim

a technology of friction drive and wind turbine, which is applied in the direction of propellers, propulsive elements, water-acting propulsive elements, etc., can solve the problems of high cost of power transmission and energy production equipment, difficulty in producing electricity with the same frequency as the grid, and system cost more than those used in fixed-speed wind turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

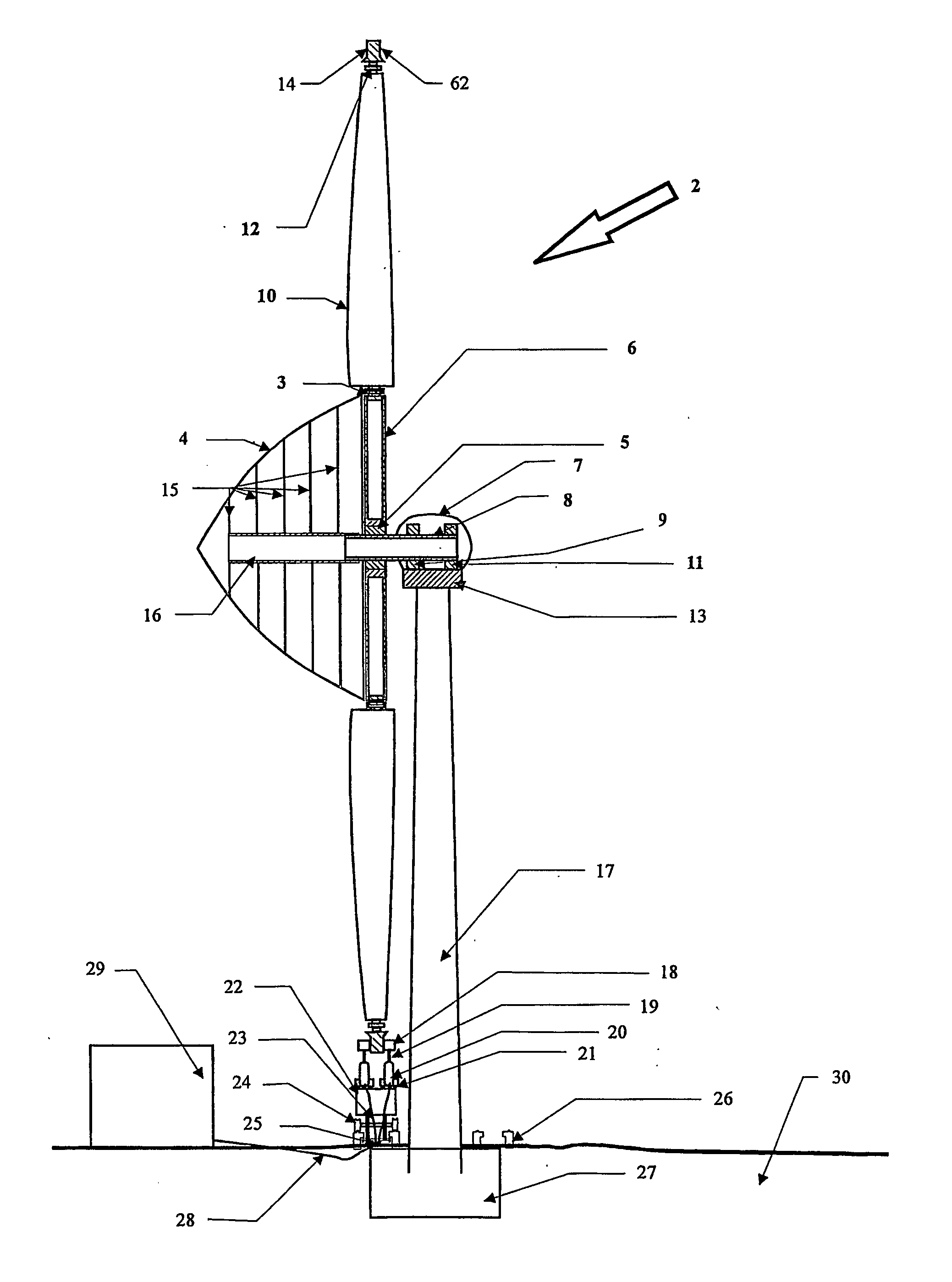

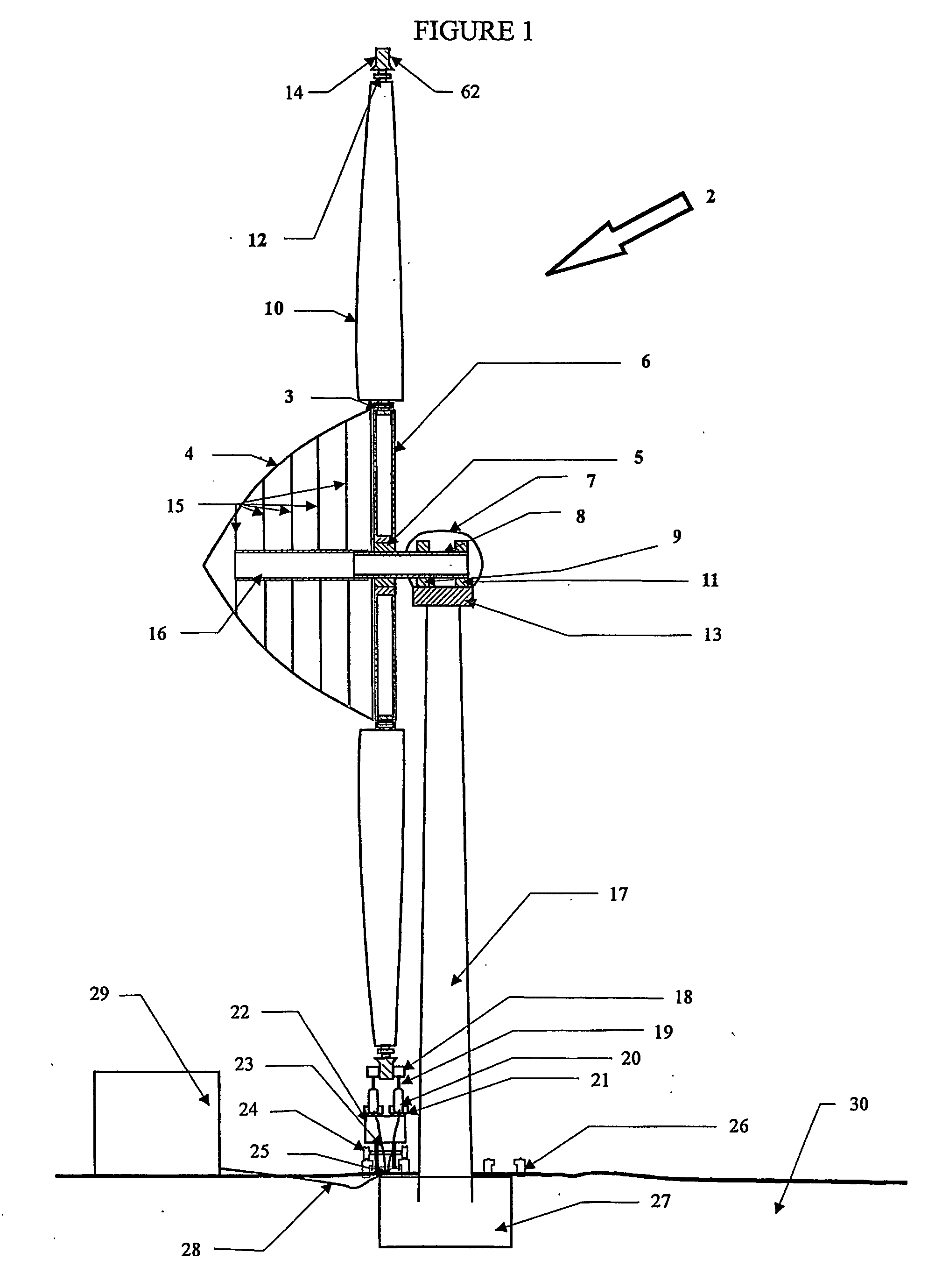

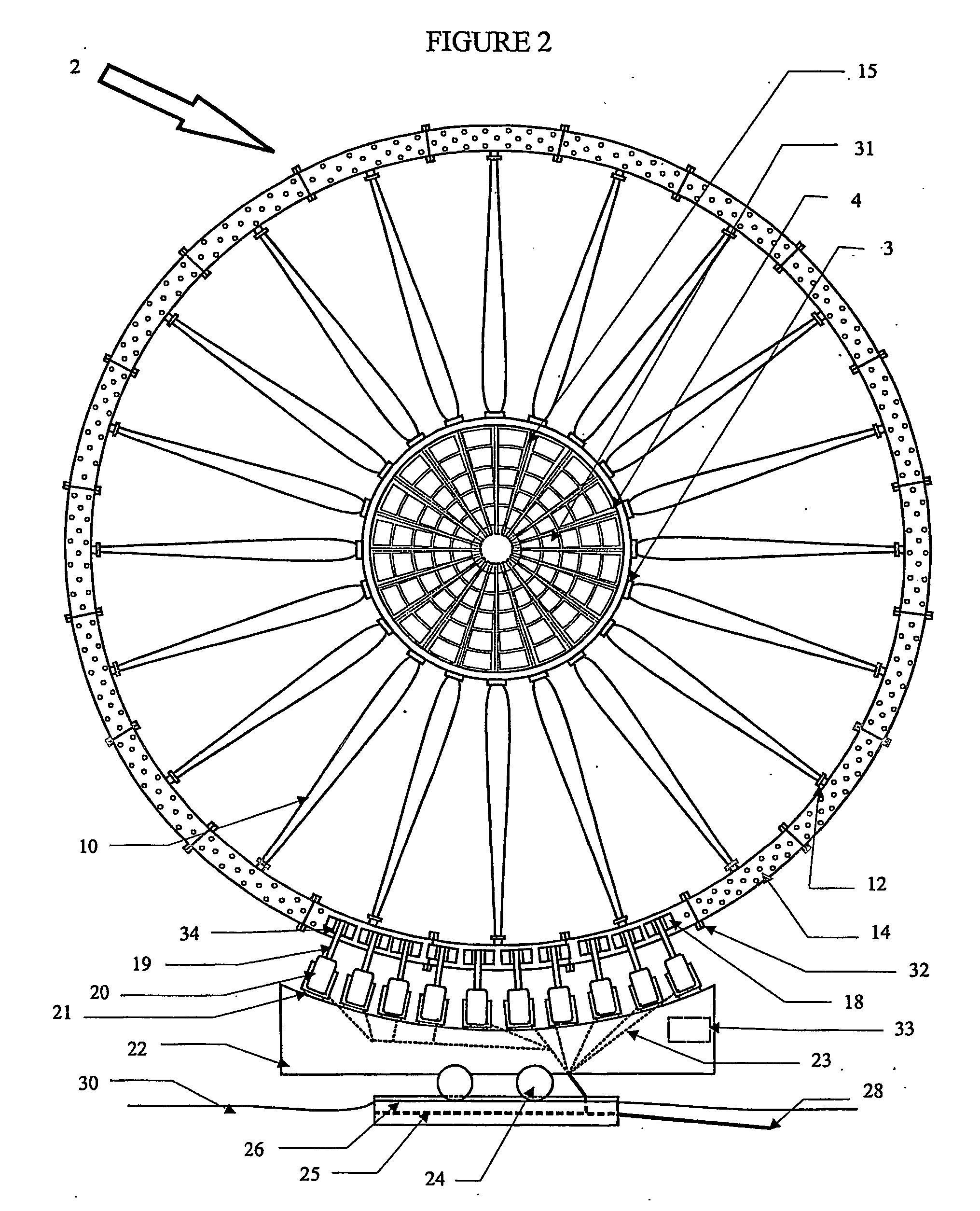

[0040] In FIGS. 1 and 2, a turbine 2 has a rotor with a hub 6 and a plurality of blades 10 extending outward from a root 3 to a tip 12. Preferably, the wind turbine has eight to twenty blades. Connected to and supported by each of the tips 12 is a ring with a front surface 14 and a back surface 62. Rotators 18 are located and mounted to be removably placed into contact with the front surface 14 and back surface 62 as the ring 1 rotates. The rotators each have a shaft 19 which is connected to energy producing equipment 20. The rotators are preferably tires mounted on a rim 34. The tires are preferably made of rubber. Steel or metal wheels can also be used as rotators. The energy producing equipment includes generators, compressors, pumps and the like. When the energy producing equipment is a generator, the rotation of the wind turbine 2 will cause the front surface 14 and back surface 62 of the ring to rotate. The tires will also rotate when they are in contact with the ring 1, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com