Mobile module for transportating a carrier from a first modular line to second modular line

a technology of mobile modules and carriers, which is applied in the direction of conveyors, mechanical conveyors, coatings, etc., can solve the problems of too expensive and time-consuming to implement, modify, remove or replace the manufacturing chain, and improve the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

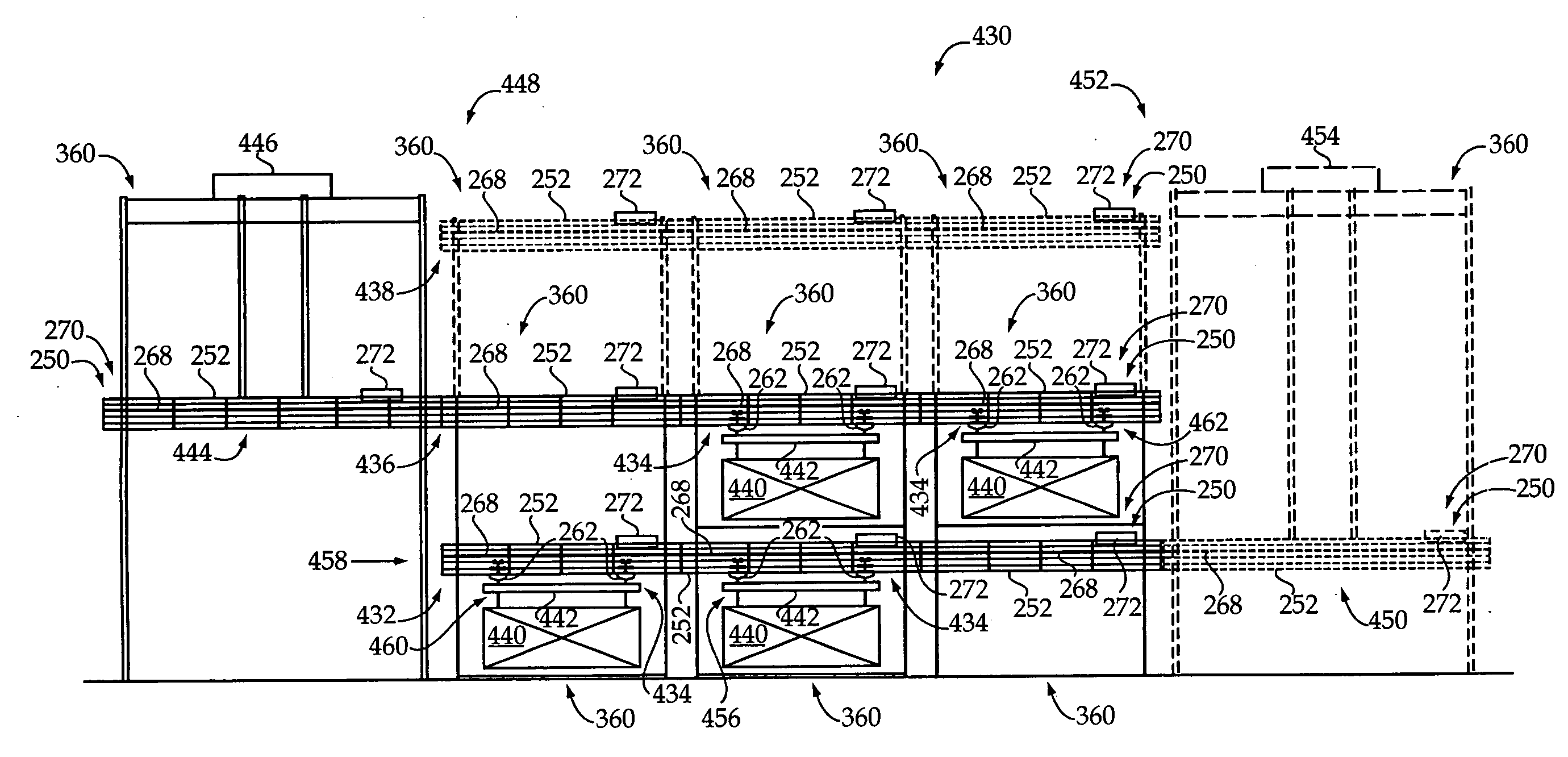

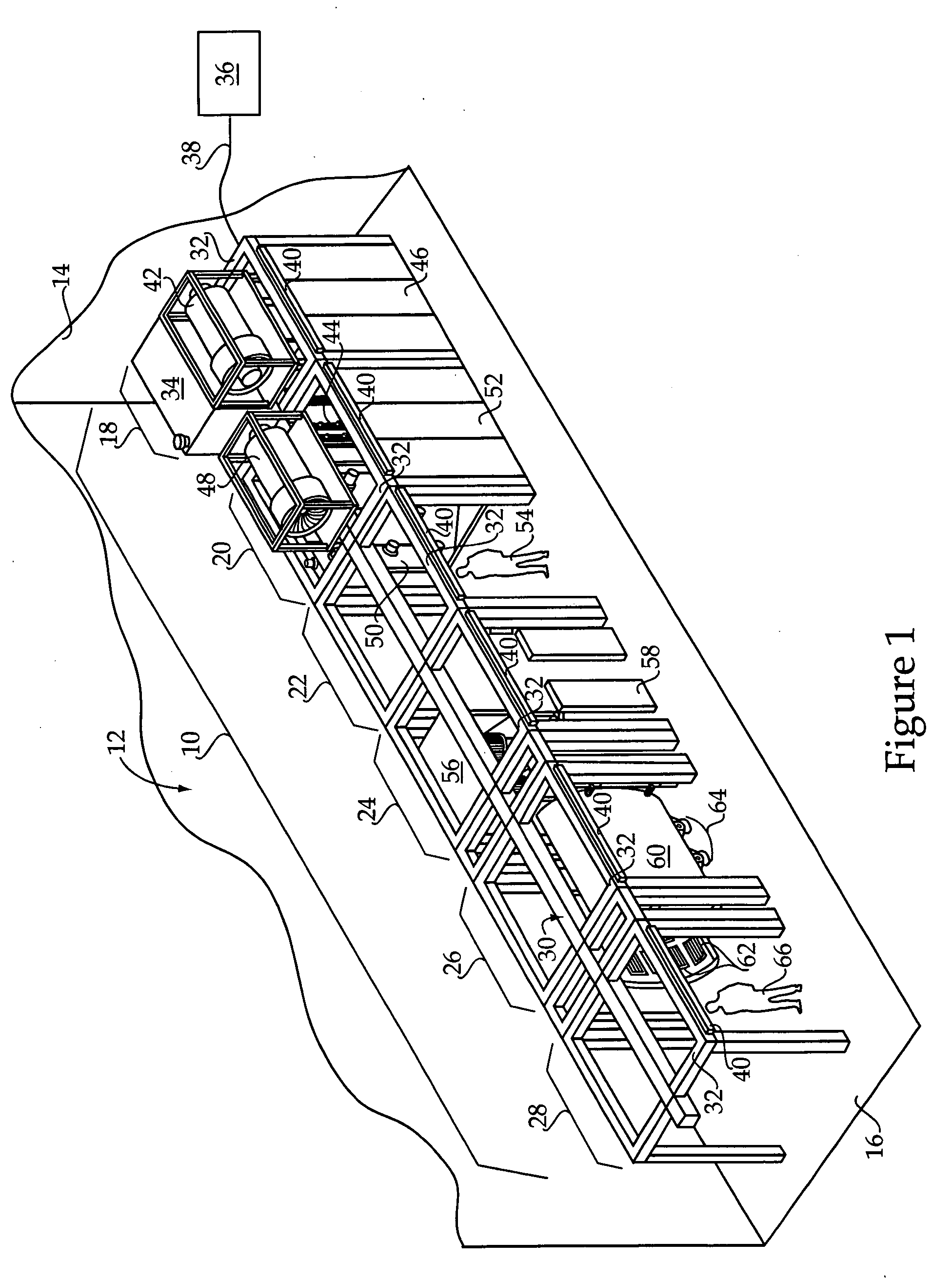

[0027]An exemplary embodiment of a manufacturing chain 10 is shown generally in FIG. 1. The manufacturing chain 10 may be disposed within a manufacturing area 12, such as, for example, a manufacturing area defined by a building 14. According to one embodiment, the manufacturing chain 10 may be secured to, and positioned above, a planar floor 16 of the manufacturing area 12. However, numerous locations and arrangements are contemplated for the manufacturing chain 10. According to the exemplary embodiment, the manufacturing chain 10 may be used to perform a paint process, such as, for example, a powder coating process, and, therefore, may also be referred to as a paint line. Although a paint process is described, however, it should be appreciated that the manufacturing chain 10 may be designed to perform any of a variety of manufacturing processes.

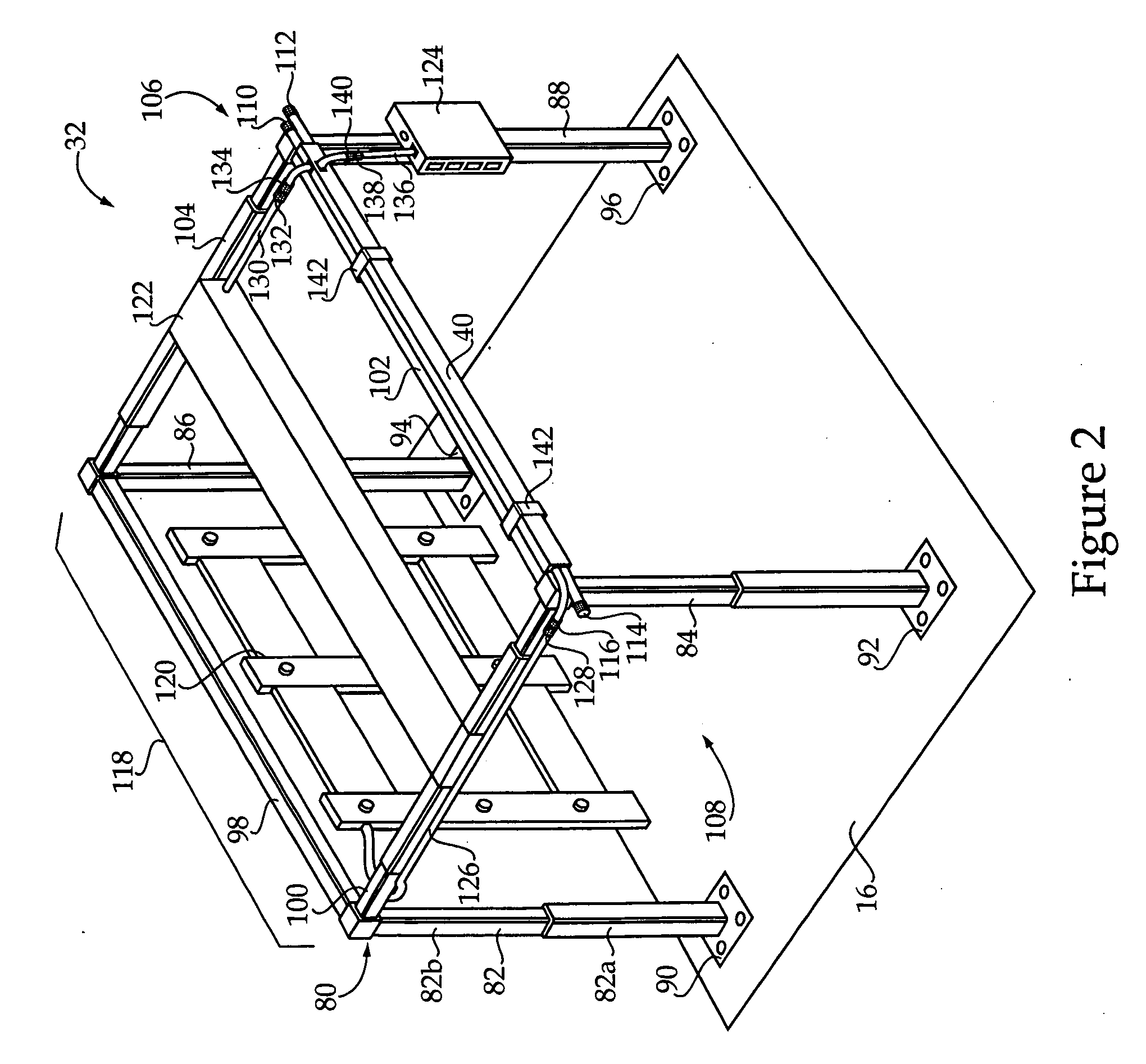

[0028]The manufacturing chain 10, also referred to as a modular manufacturing chain, may include several modular manufacturing stations, su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com