Vehicle conveyer

A technology for conveying devices and vehicles, which is applied to railway vehicles, transportation and packaging, conveyors, etc., and can solve problems such as increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

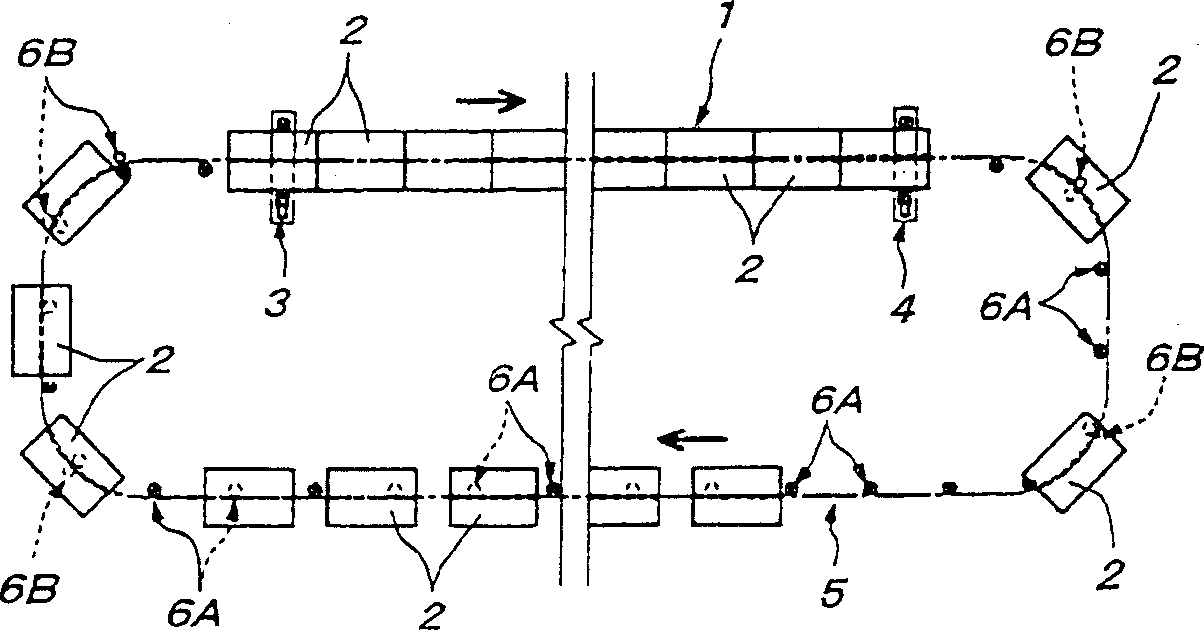

[0022] see Figure 1A , the main running line 1 of an assembly process is a linear running line. The rear (starting) end of the running line 1 is equipped with a transmission device 3 as the main driving force for pushing the vehicle 2 forward. The front end of the running line 1 is equipped with a braking device 4 that prevents the vehicle 2 from running at a speed higher than a predetermined speed. A secondary running line 5 can continue to make the vehicle 2 return from the front end of the main running line 1 to the rear end. The auxiliary running line 5 is equipped with a plurality of transmission devices 6A and 6B as auxiliary driving force at intervals smaller than the entire length of the vehicle 2 . These transmissions 6A and 6B each push the vehicles 2 forward one by one at high speed.

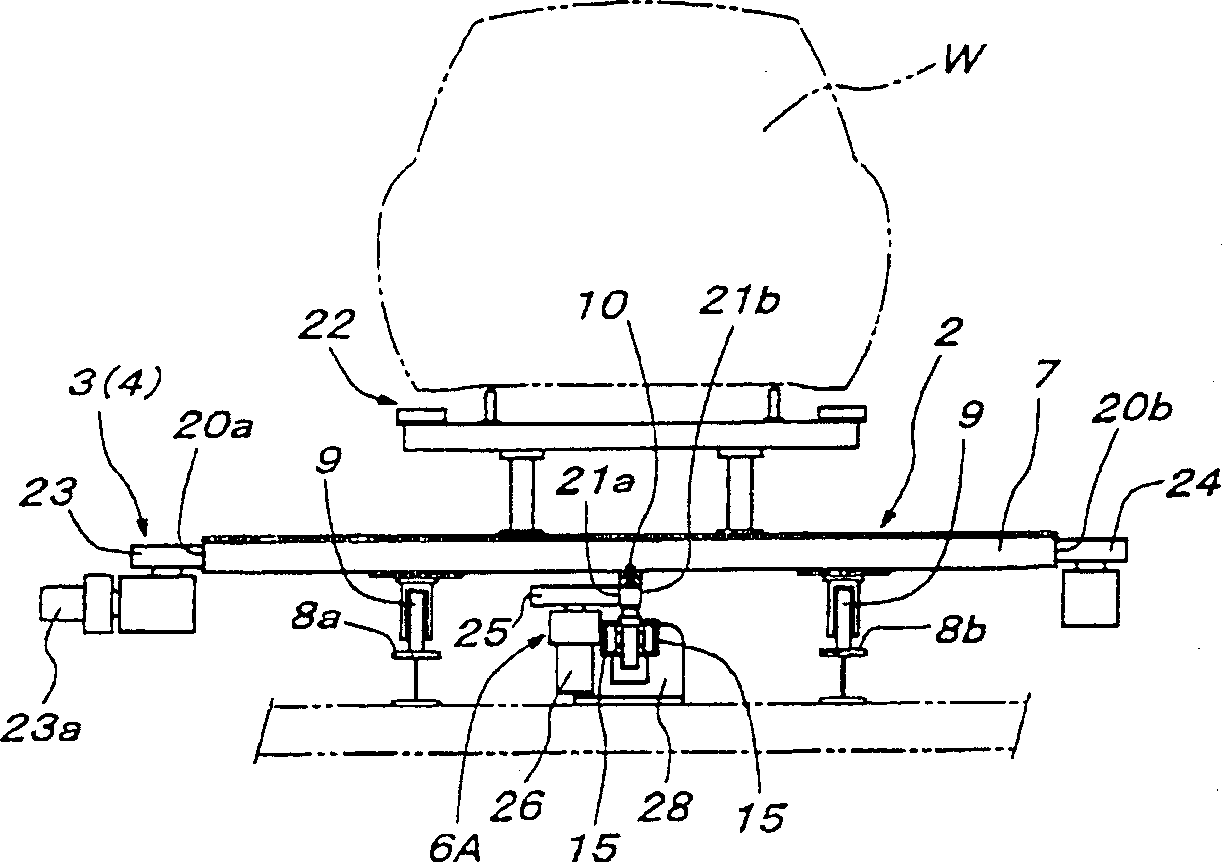

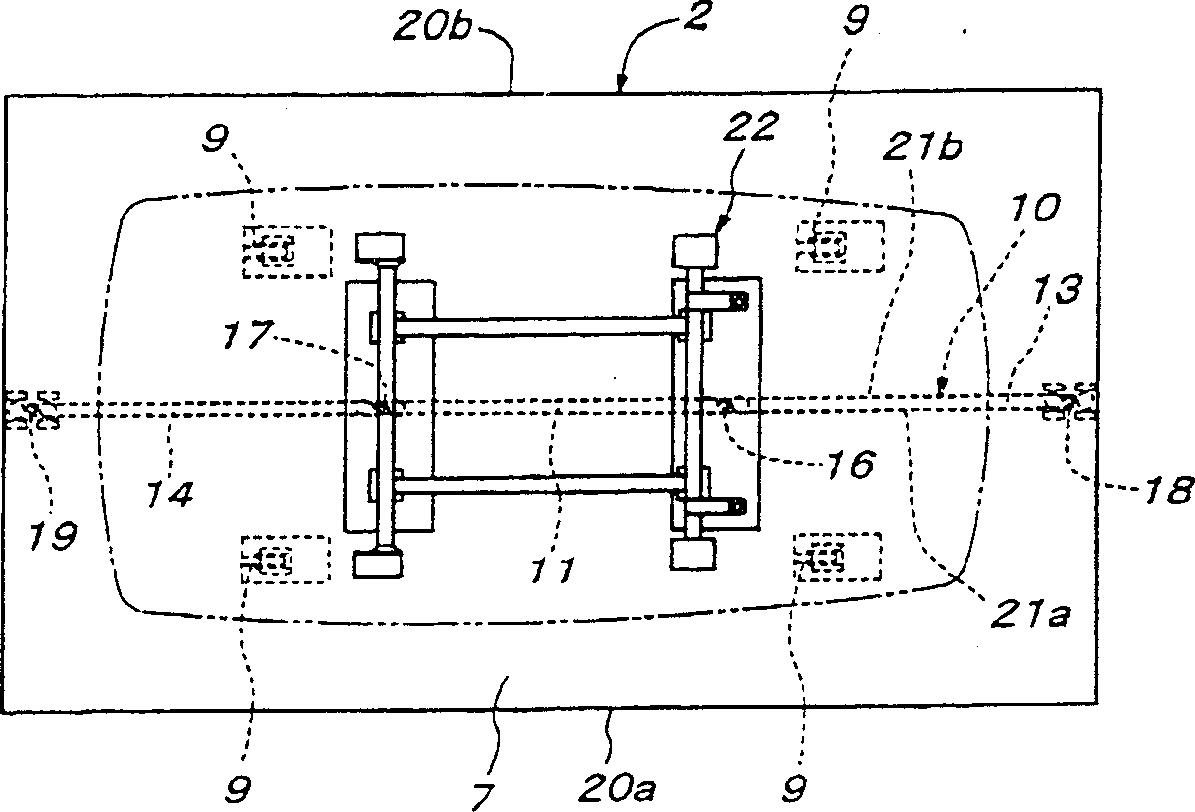

[0023] Such as Figure 1B , 2 As shown in and 3, each vehicle 2 includes a rectangular vehicle floor 7 that is longer in the vehicle running direction. A pair of front freewheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com