Stepless speed change device of circularly arranged cone pulleys

A technology of continuously variable speed changer and bevel wheel, which is applied in the direction of transmission device, friction transmission device, belt/chain/gear, etc., can solve the problems of non-transmission, complex structure, high processing precision requirements, etc., and achieve reliable performance, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

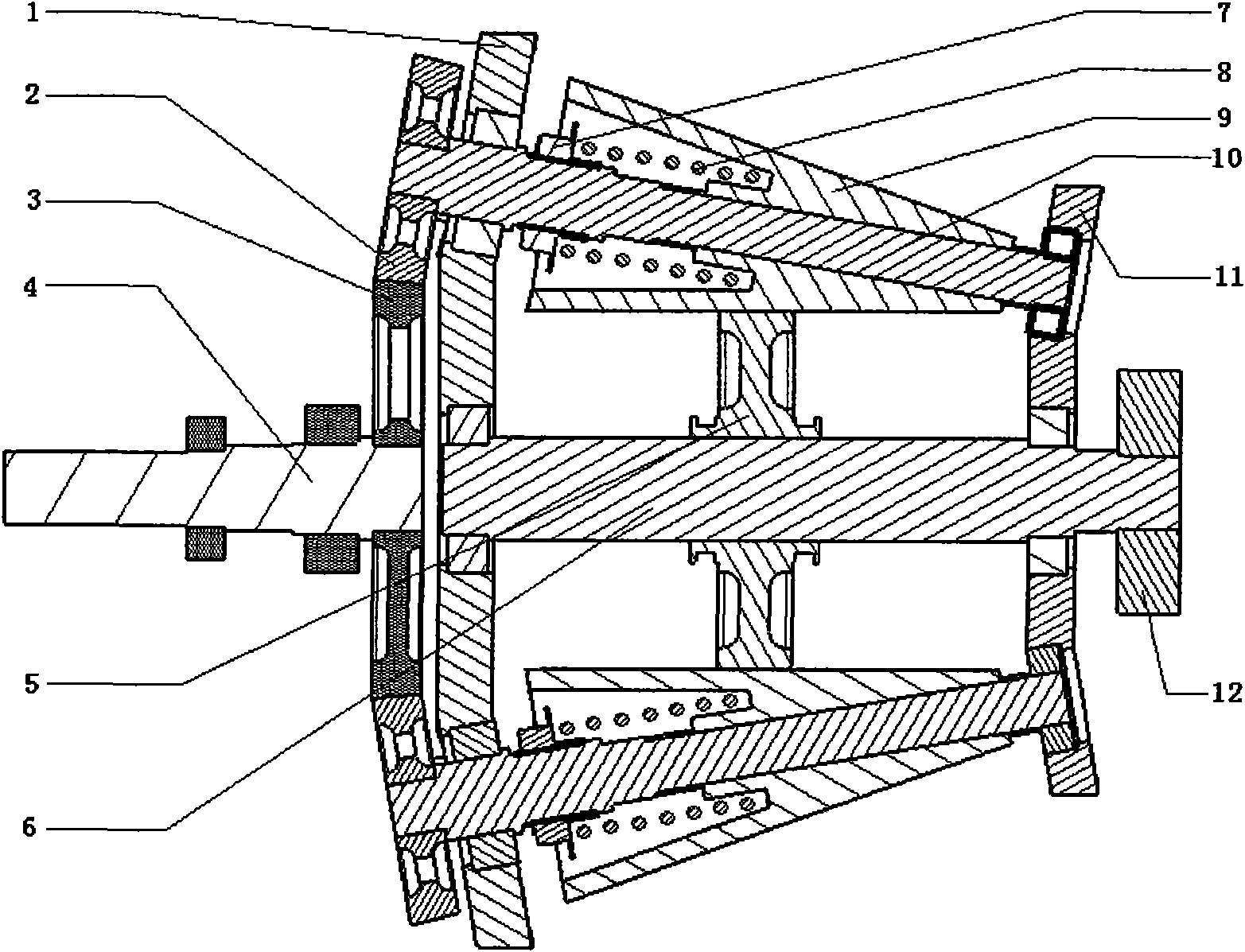

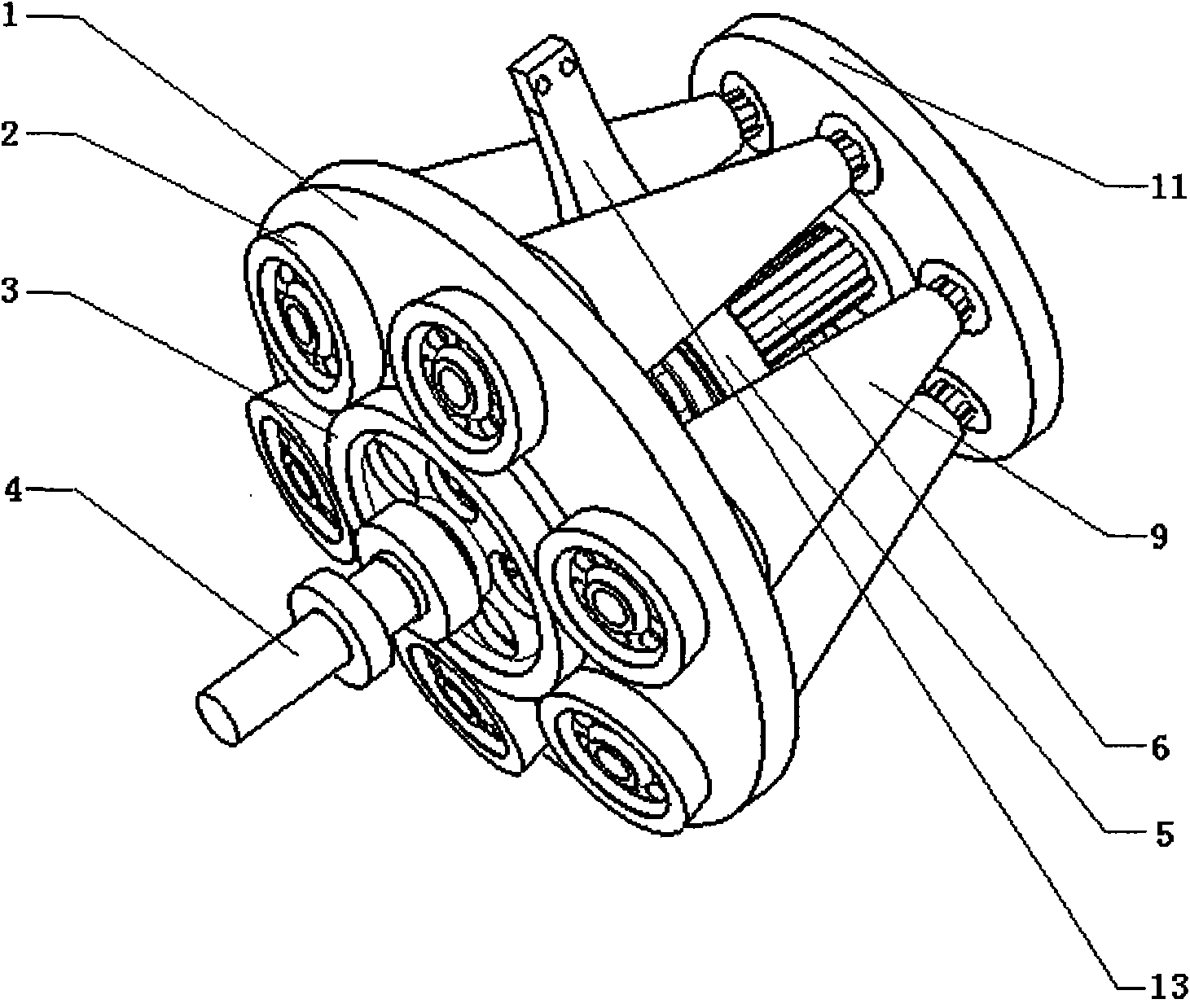

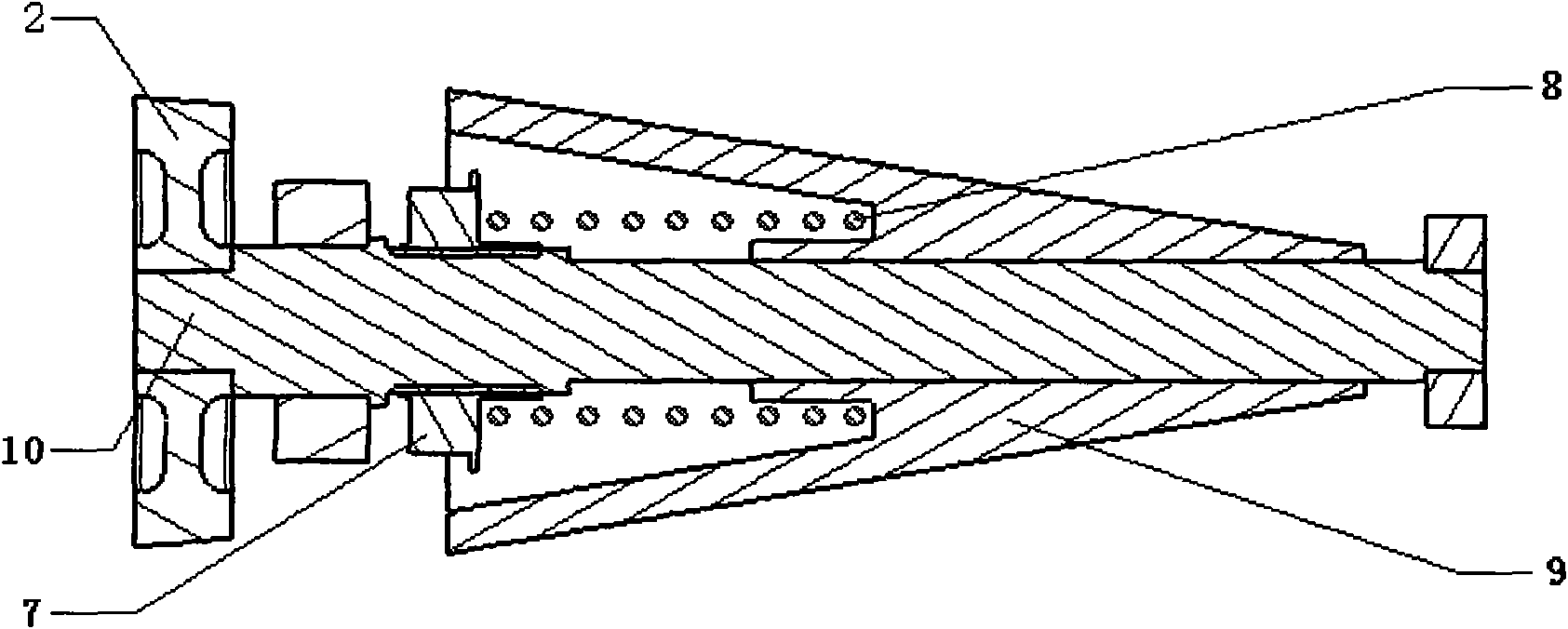

[0023] like figure 1 , figure 2 As shown, the ring cloth bevel wheel continuously variable transmission device of the present invention includes a driven shaft 6 located in the center, and a plurality of driving shafts 10 are arranged around the driven shaft 6, six in this embodiment, and the driving shafts 10 are arranged along the The rings are evenly distributed around the driven shaft 6 . Both ends of the driven shaft 6 and the driving shaft 10 are respectively supported on the bases 1 and 11 through bearings.

[0024] A cylindrical friction wheel 5 is sleeved on the driven shaft 6, and the surface of the driven shaft 6 is provided with a longitudinal chute, and the inner hole of the cylindrical friction wheel 5 is also provided with a spline groove, so the cylindrical friction wheel 5 and the driven The connection mode between the shafts 6 is spline fit, and the cylindrical friction wheel 5 and the driven shaft 6 can move axially, but cannot rotate relatively.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com