Trolley flexible transport system and application method thereof

A conveying system and trolley-type technology, which is applied in the field of trolley-type flexible conveying system, can solve the problems of planning, design, construction lengthening, complex structure of workshop and building, and increase of project cost, so as to reduce hanging load and civil construction investment , the effect of reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

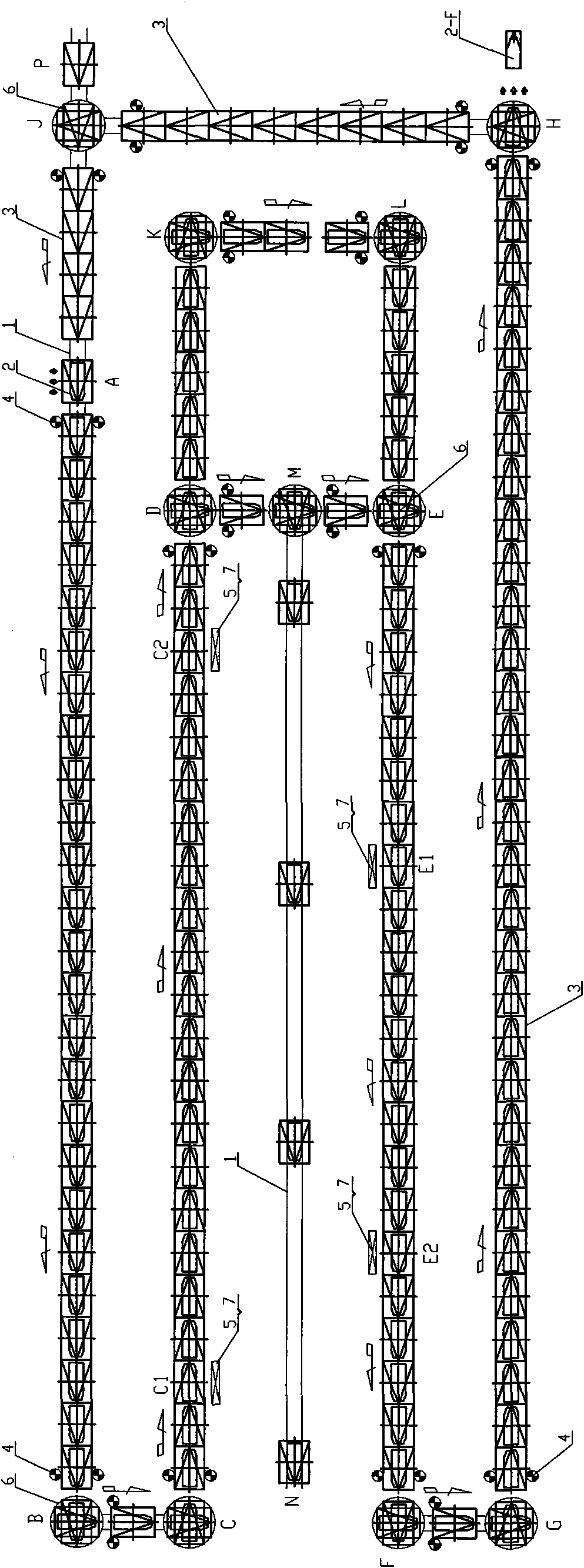

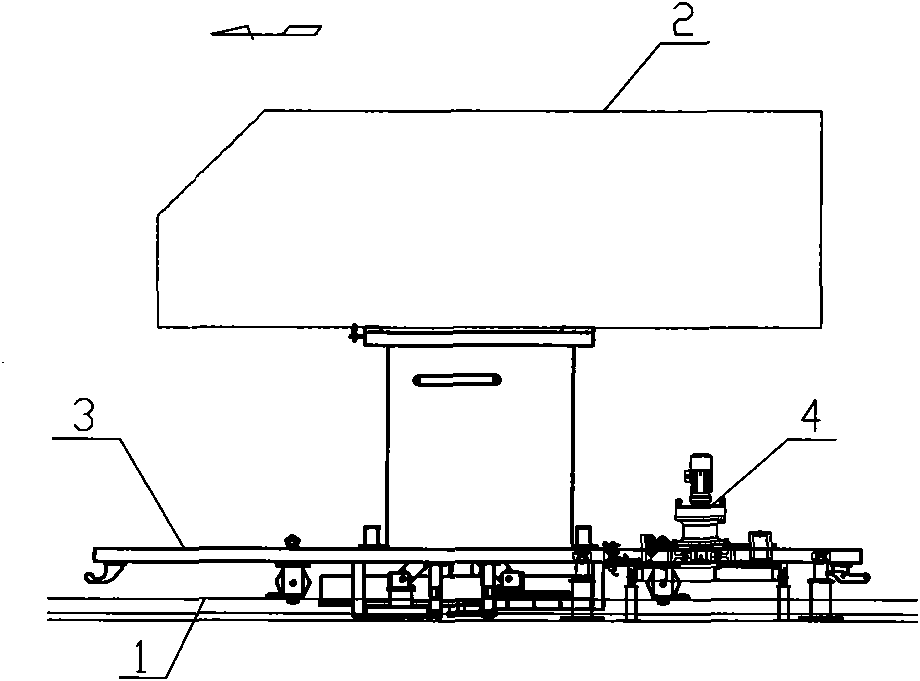

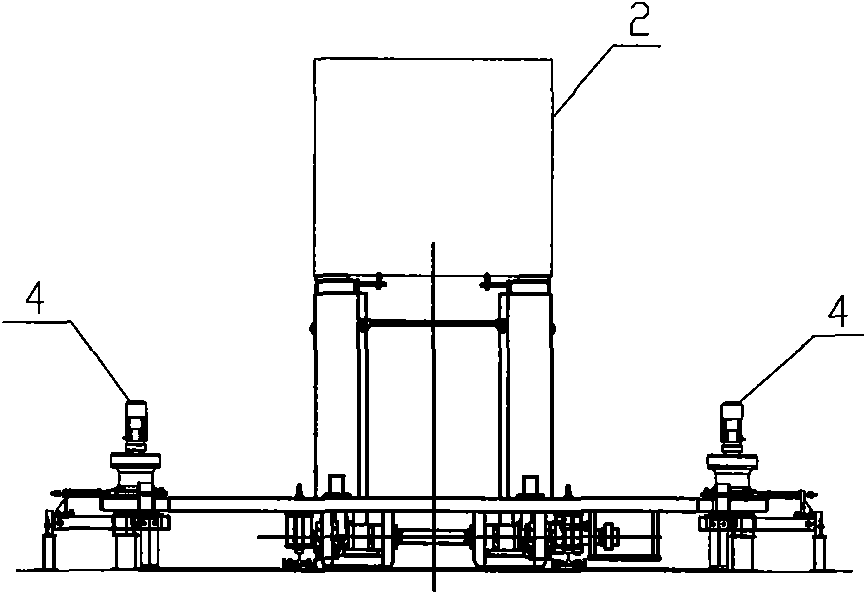

[0081] Such as figure 1 As shown, the present invention is mainly composed of a plurality of omni-directional assembly trolleys 3 for assembly, a turntable 6 and a corresponding length of track 1 and multiple groups of friction drive devices 4. Each all-round assembly trolley 3 is regarded as a station, and multiple all-round assembly trolleys 3 are arranged according to the process sequence to form a whole; turntables 6 are set at the places where turning is required. Constitute a closed loop production line.

[0082] exist figure 1 In the process, the workpiece 2 is put on the line at station A and placed on the trolley 3 for omnidirectional assembly. Then carry out the process operation sequentially. During the operation of section A-B, two sets of friction drive devices 4 are arranged to provide horizontal running power for this group of trolleys. During the operation of section A-B, workers perform low-position or fixed-height operations on the workpiece.

[0083] At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com