Polyamide 5X high-strength fiber and preparation method thereof

A polyamide, high-strength technology, applied in the field of polyamide materials, can solve the problems of increased operation steps and costs, and decreased mechanical properties of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] The invention relates to a polyamide 5X high-strength yarn and a preparation method thereof.

[0088]

[0089] The raw materials for the production of polyamide 5X high-strength yarn of the present invention at least include: 1,5-pentamethylenediamine and dicarboxylic acid; or, polyamide obtained by polymerization of 1,5-pentamethylenediamine and dicarboxylic acid as monomers 5X.

[0090] Dicarboxylic acids may include short chain dibasic acids and / or long chain dibasic acids. The short-chain dibasic acid may be selected from any one of succinic acid, glutaric acid, adipic acid, pimelic acid, suberic acid, azelaic acid or sebacic acid. The long-chain dibasic acid can be selected from undecane dibasic acid, dodecane dibasic acid, tridecane dibasic acid, tetradecane dibasic acid, pentadecane dibasic acid, hexadecane dibasic acid, Any one of heptadecandioic acid, octadecanedioic acid, maleic acid, or Δ9-1,18 octadecenedioic acid.

[0091] In polyamide 5X, X can be an ...

Embodiment 1

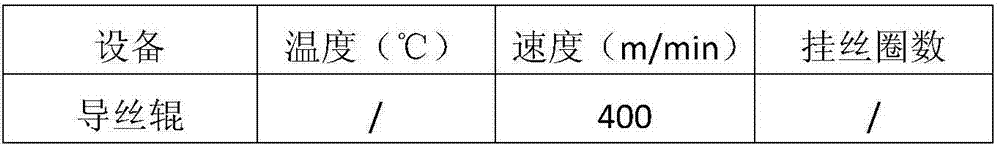

[0188] Example 1: Polyamide 56 high-strength wire (1670dtex / 192f)

[0189] The present embodiment provides a kind of preparation method of polyamide 56 high-strength silk, it comprises the steps:

[0190] (1), heating the polyamide 56 resin to a molten state to form a polyamide 56 melt;

[0191] (2), polyamide 56 melt is carried out spinning, forms as-spun silk;

[0192] (3) Polyamide 56 high-strength yarn is obtained after processing the as-spun yarn.

[0193] Wherein, in the step (1), the relative viscosity of the polyamide 56 resin (in slice form) is 3.4, which is prepared by a biological fermentation method.

[0194] The heating in step (1) is carried out in a single-screw extruder, and the screw extruder is divided into five zones for heating. The temperature in the first zone is 270°C, the temperature in the second zone is 290°C, and the temperature in the third zone is 300°C. The temperature in the fourth zone is 305°C, and the temperature in the fifth zone is 300°C....

Embodiment 2

[0201] Embodiment two: Polyamide 56 high-strength wire (2800dtex / 480f)

[0202] The present embodiment provides a kind of preparation method of polyamide 56 high-strength silk, it comprises the steps:

[0203] (1), heating the polyamide 56 resin to a molten state to form a polyamide 56 melt;

[0204] (2), polyamide 56 melt is carried out spinning, forms as-spun silk;

[0205] (3) Polyamide 56 high-strength yarn is obtained after processing the as-spun yarn.

[0206] Wherein, in the step (1), the relative viscosity of the polyamide 56 resin (in slice form) is 3.6, which is prepared by a biological fermentation method.

[0207] The heating in the step (1) is carried out in a single-screw extruder, and the screw extruder is divided into five zones for heating, the temperature in the first zone is 285°C, the temperature in the second zone is 305°C, and the temperature in the third zone is 310°C. The temperature in the fourth zone is 315°C, and the temperature in the fifth zone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| winding tension | aaaaa | aaaaa |

| winding tension | aaaaa | aaaaa |

| winding tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com