Hollow fiber, dope solution composition for forming a hollow fiber, and method for manufacturing a hollow fiber using the same

A fiber, hollow technology, applied in the manufacture of hollow filaments, chemical instruments and methods, single-component synthetic polymer rayon, etc., can solve the problems of difficulty in obtaining separation and permeability, and membrane performance degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

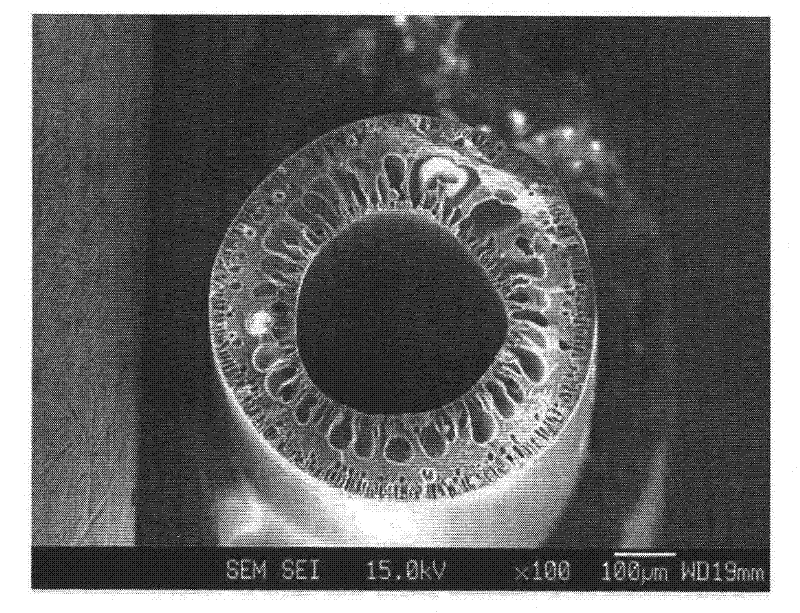

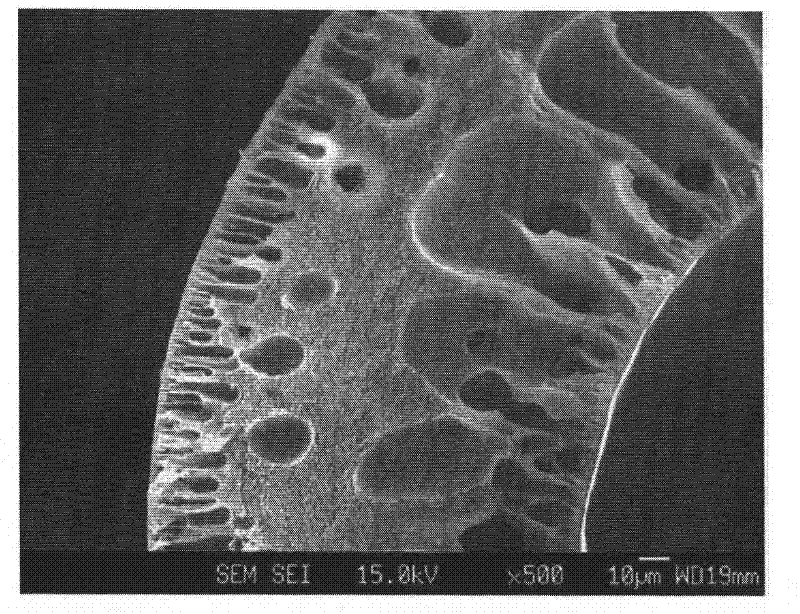

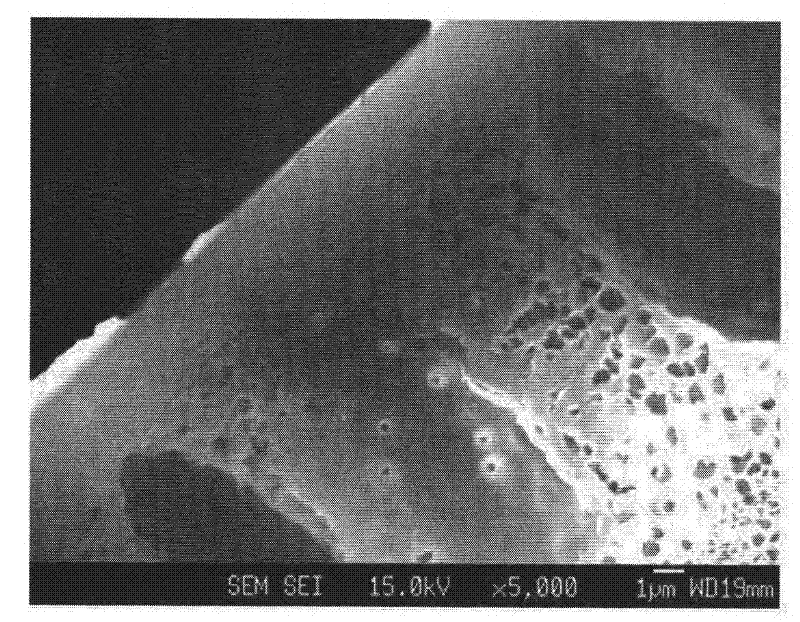

Image

Examples

Embodiment 1

[0412] A hollow fiber including polybenzoxazole represented by Chemical Formula 51 was prepared through Reaction Scheme 3 below using a doping solution composition for forming a hollow fiber containing polyhydroxyamic acid.

[0413] [Reaction Scheme 3]

[0414]

[0415] (1) Preparation of polyhydroxyamic acid

[0416] Add 36.6g (0.1mol) of 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane and 44.4g (0.1mol) of 4,4'-(hexafluoroisopropene)diphthalic anhydride into 189 g (70 wt%) of N-methylpyrrolidone (NMP) and then reacted at 15° C. for 4 hours to obtain pale yellow viscous polyamic acid.

[0417] (2) Preparation of doping solution composition for forming hollow fiber

[0418] The obtained polyamic acid was added to 5 wt% of tetrahydrofuran as an additive without removing the solvent to prepare a uniform doping solution composition for forming a hollow fiber.

[0419] (3) Preparation of hollow fiber

[0420] The doping solution composition for forming a hollow fiber was ...

Embodiment 2

[0424] A hollow fiber including polybenzothiazole represented by Chemical Formula 52 was prepared through the following reaction using a doping solution composition for forming a hollow fiber containing polythioamic acid.

[0425] [chemical formula 52]

[0426]

[0427] A hollow fiber including polybenzothiazole represented by the above Chemical Formula 52 was prepared in the same manner as in Example 1, except that the starting material, 20.8 g (0.1 mol) of 2,5-diamino-1,4- Benzothiophene dihydrochloride and 44.4 g (0.1 mol) of 4,4'-(hexafluoroisopropylene) diphthalic anhydride were reacted to prepare a polyamic acid containing a thiol group (-SH).

[0428] The hollow fiber thus prepared had a weight average molecular weight of 14,500. As a result of FT-IR analysis, polybenzothiazole at 1484cm -1 (C-S) and 1404cm -1 The characteristic bands of (C-S) were not detected in polyimide. The hollow fiber has a free volume fraction of 0.26 and a interplanar spacing (d-spacing)...

Embodiment 3

[0431] A hollow fiber including polypyrrone represented by Chemical Formula 53 was prepared by the following reaction using a doping solution composition for forming a hollow fiber containing polyaminoamic acid.

[0432][chemical formula 53]

[0433]

[0434] A hollow fiber comprising polypyrrone represented by the above Chemical Formula 53 was prepared in the same manner as in Example 1, except that the starting materials, 21.4 g (0.1 mol) of 3,3'-diaminobenzidine and 44.4 g (0.1mol) of 4,4′-(hexafluoroisopropene) diphthalic anhydride was reacted to prepare 2 ) of polyamic acid.

[0435] The hollow fiber thus prepared had a weight average molecular weight of 18,000. As a result of FT-IR analysis, the polypyrrone at 1758cm -1 (C=O) and 1625cm -1 The characteristic frequency band of (C=N) was not detected in polyimide. The hollow fiber has a free volume fraction of 0.28 and a interplanar spacing (d-spacing) of 630 pm.

[0436] The interplanar spacing (d-spacing) was de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Free volume fraction | aaaaa | aaaaa |

| Free volume fraction | aaaaa | aaaaa |

| Free volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com