Low-melting-point and flame-retarding copolymerized nylon and preparation method thereof

A technology of copolymerized nylon and low melting point, which is applied in the field of low melting point flame-retardant copolymerized nylon and its preparation, which can solve the problems of unseen industrial products and achieve the effects of simple method, good compatibility and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The first part preparation of flame retardant containing P

[0036] In Reactor 1, put 100 moles of DOPO derivatives and solvent absolute ethanol into it, heat to 70°C, under strong stirring, the DOPO derivatives are evenly dispersed in absolute ethanol, and then cool down to 48°C or 49°C or 50°C or 51°C or 52°C, then add 100 moles of diamine, stir and mix to make the reaction complete (the reaction time is generally 3 to 5 hours), cool down to 40°C and filter with suction to obtain a P-containing flame retardant agent.

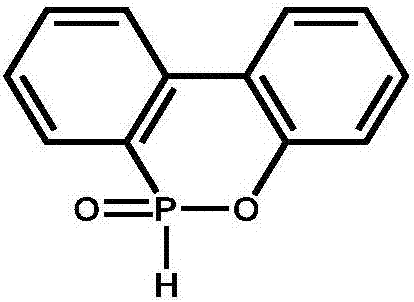

[0037] The DOPO derivative is DOPOMA (its structural formula is ) and DOPOITA (its structural formula is: ).

[0038] The diamine is hexamethylenediamine or decanediamine.

[0039] The P-containing flame retardants prepared by DOPO derivative DOPOMA and hexamethylenediamine or decanediamine are P1 flame retardants and P2 flame retardants respectively. The P-containing flame retardants prepared by DOPO derivative DOPOITA and hexamethylenediamine o...

Embodiment 29

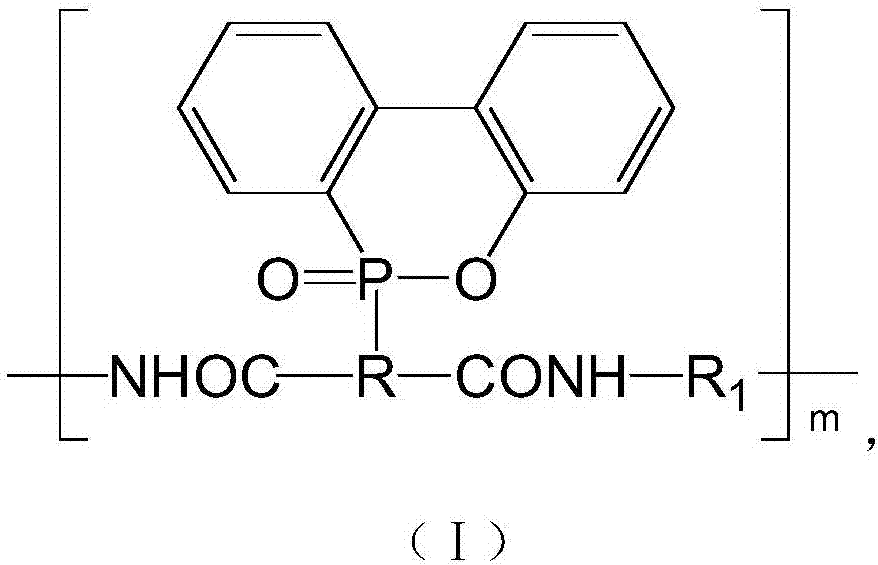

[0057] A low melting point flame retardant copolymerized nylon, the low melting point flame retardant copolymerized nylon has the chemical structural formula shown in formula (I):

[0058]

[0059] In formula (I): m=10~50, R can be saturated C2~C10 linear, branched or cyclic alkylene, in R 1 In the structural formula of a=0~30, b=0~30, c=0~10, d=0~20, e=0~20, f=0~10, and a, b, c, d, e, f is not 0 at the same time, A 1 =-NH(CH 2 ) 6 NH-, A 2 =-NH(CH 2 ) 10 NH-, B 1 =-CO(CH 2 ) 8 CO-, B 2 =-CO(CH 2 ) 10 CO-, B 3 =-CO(CH 2 ) 4 CO-;

[0060] The low-melting point flame-retardant copolymerized nylon is a transparent non-crystalline glass-like polymer with a melting point range of 100-130°C, a relative viscosity of 2.0-2.80, a limiting oxygen index of 28-32%, and a flame-retardant level of UL-94V-0. class.

Embodiment 30

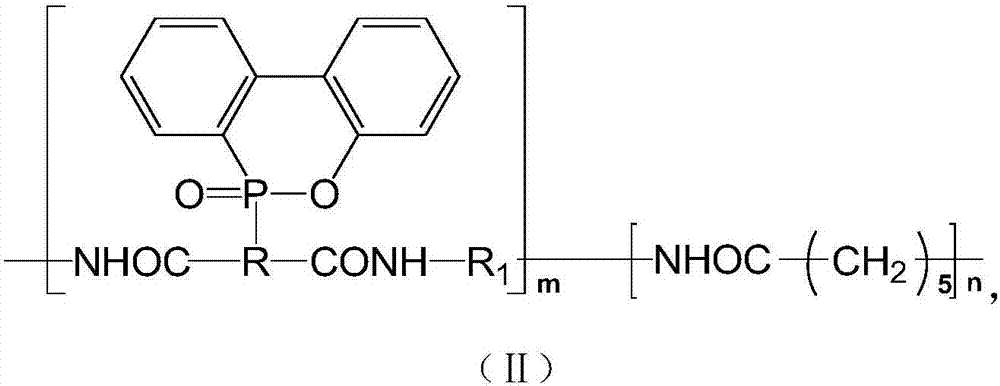

[0062] A low-melting point flame-retardant copolymerized nylon, which has a chemical structural formula shown in formula (II):

[0063]

[0064] In formula (II): m=10~50, n=1~15, R can be saturated C2~C10 linear, branched or cyclic alkylene, in R 1 In the structural formula of a=10~30, b=10~30, c=0~10, d=5~20, e=5~20, f=0~10, and a, b, c, d, e, f is not 0 at the same time, A 1 =-NH(CH 2 ) 6 NH-, A 2 =-NH(CH 2 ) 10 NH-, B 1 =-CO(CH 2 ) 8 CO-, B 2 =-CO(CH 2 ) 10 CO-, B 3 =-CO(CH 2 ) 4 CO-;

[0065] The low-melting point flame-retardant copolymerized nylon is a transparent non-crystalline glass-like polymer with a melting point range of 100-130°C, a relative viscosity of 2.0-2.80, a limiting oxygen index of 28-32%, and a flame-retardant level of UL-94V-0. class.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com