Biomass based polyamide resin

A polyamide resin, biomass technology, applied in the field of polyamide resin, can solve the problems of poor thermal stability, poor molding cycle, poor thermodynamic properties, etc., and achieve excellent mechanical properties, excellent thermodynamic properties, and high chemical resistance. medicinal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Add 592.8g (3.8mol) furan-2,5-dicarboxylic acid, 33.2g (0.2mol) terephthalic acid, 688g (4mol) 1,10-decanediamine, 2.62 (0.12mol) benzene in 3L autoclave Formic acid, 2.62g (0.2wt% based on the total amount of raw materials) sodium hypophosphite monohydrate, 0.5L deionized water, nitrogen purging and then heating up. While stirring, the temperature was raised to 215° C. over about 2 hours, and the pressure inside the autoclave was raised to 2 MPa at this time. The reaction was continued under this condition for 2 hours, then the temperature was raised to 240° C., and kept under this condition for 2 hours, water vapor was slowly removed, and the pressure was maintained at 2 MPa for the reaction. Next, the pressure was lowered to 1 MPa over 1 hour, and the reaction was further carried out for 1 hour to obtain a prepolymer having a relative viscosity of 1.6.

[0052] The obtained prepolymer was dried under reduced pressure at 80°C for 20 hours, crushed to a particle size ...

Embodiment 2

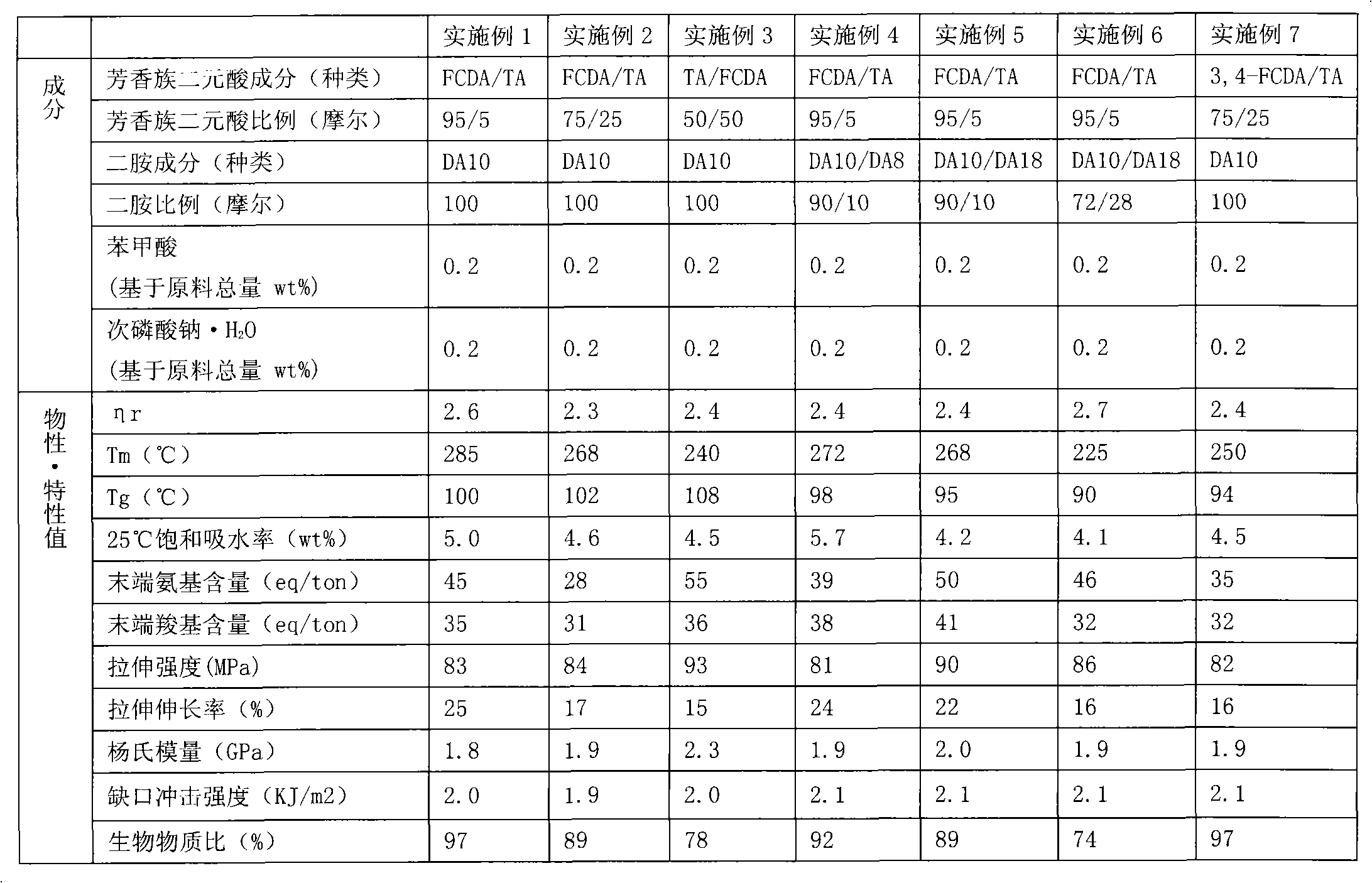

[0054] Example 1 was repeated, except that the molar ratio of furan-2,5-dicarboxylic acid to terephthalic acid was 75:25. The results are shown in Table 1.

Embodiment 3

[0056] Example 1 was repeated except that the molar ratio of furan-2,5-dicarboxylic acid to terephthalic acid was 50:50. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com