Device and method for ring-shaped electrostatic spinning in gravity direction

An electrospinning, gravity technology, used in filament/thread forming, textile and papermaking, feeding solution to spinnerets, etc. and other problems, to achieve the effect of breaking through the limitations of the production direction, reducing the liquid surface pores, and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

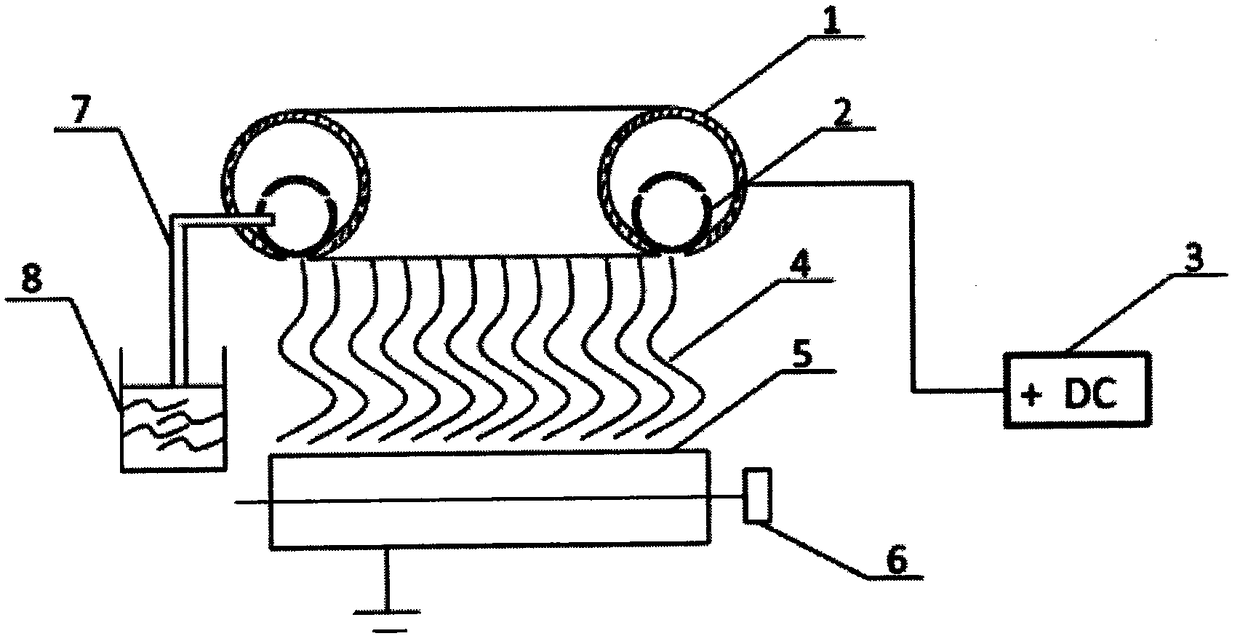

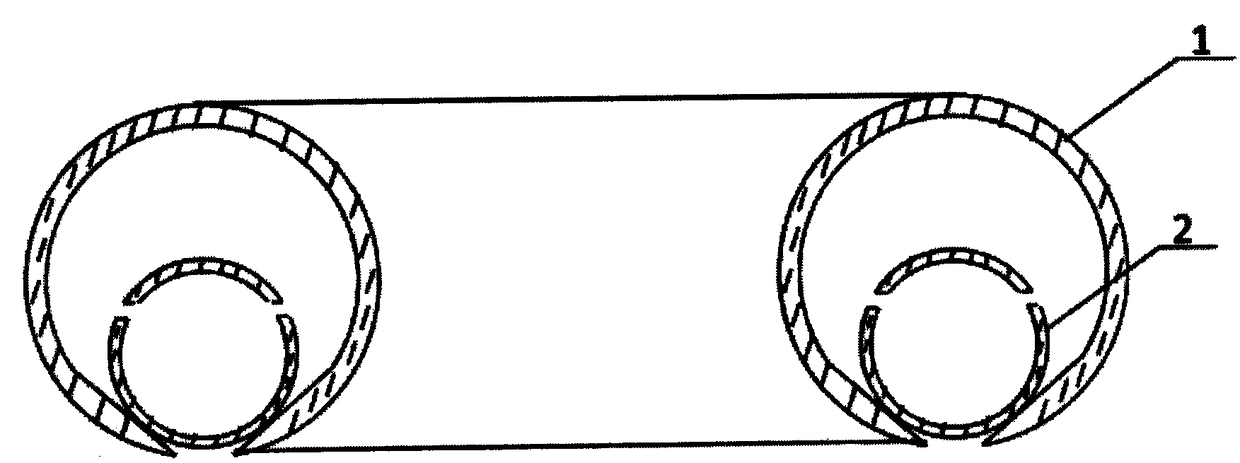

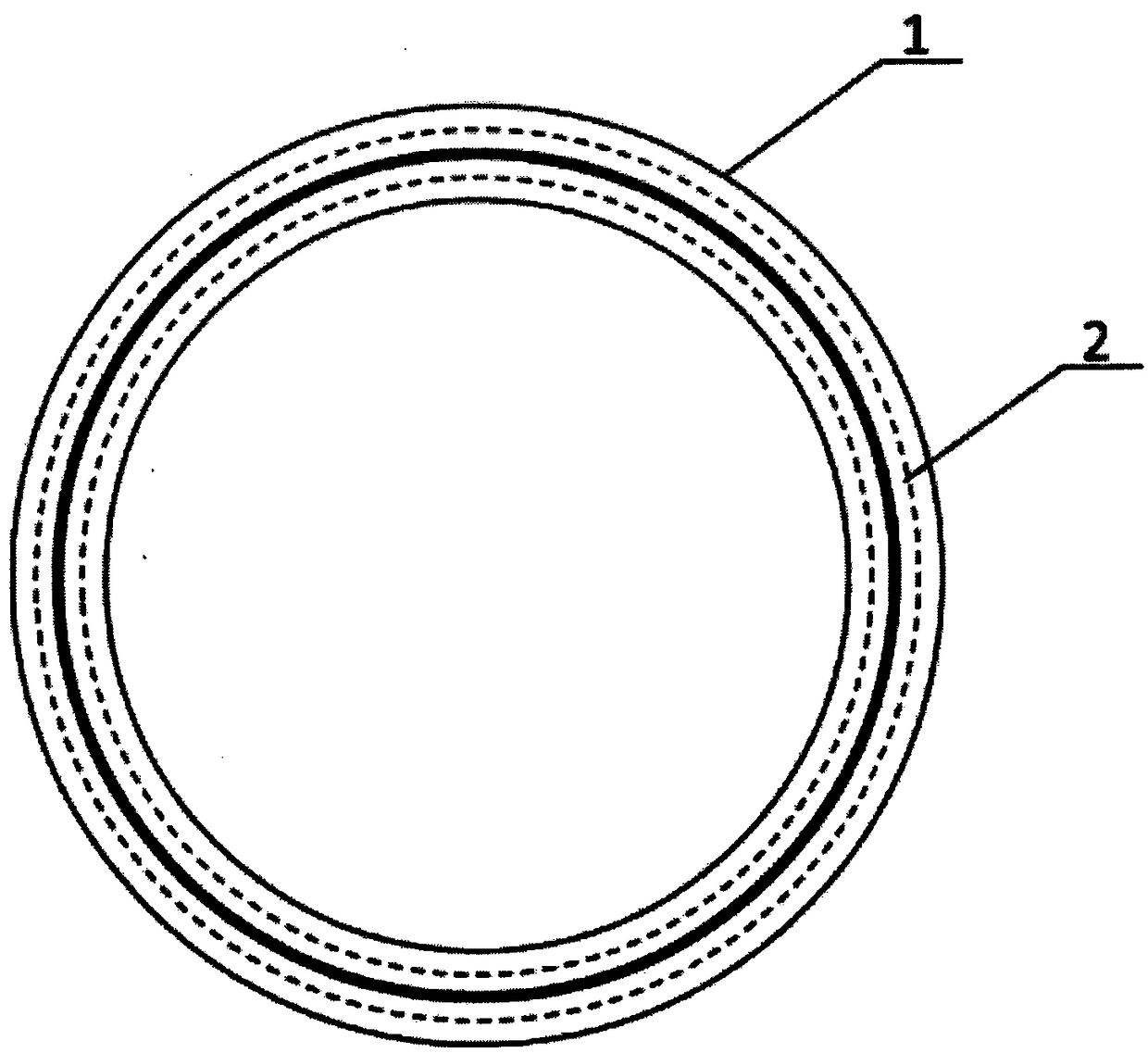

[0024] The gravitational double-layer brush-type electrospinning device adopted in this embodiment is as follows: Figure 1-3 As shown, it includes a real gravity ring electrospinning device, which is characterized in that it includes a ring-shaped nozzle 1 and a ring-shaped liquid supply device 2 nested in each other, and the ring-shaped liquid supply device 2 is located inside the ring-shaped nozzle 1 In the hollow structure, and the annular spray head 1 is tangent to the section of the annular liquid supply device 2 . And be connected with the solution propeller 8 outside of ring nozzle 1 by flexible pipe 7, ring nozzle 1 is connected with the anode of high pressure generator 3, and the bottom of ring nozzle 1 is provided with the cylinder 5 that is used for collecting, and cylinder 5 is connected with variable frequency motor 6; There is a cavity inside the ring-shaped liquid supply device 2, and two gaps are arranged symmetrically on the top of the ring-shaped liquid supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com