A kind of gravitational cylindrical electrospinning device and method

An electrospinning, cylindrical technology, applied in the direction of electrospinning, filament/thread forming, textiles and papermaking, etc., can solve the problem of single spinning direction from bottom to top, and limit the wide application of electrospinning technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

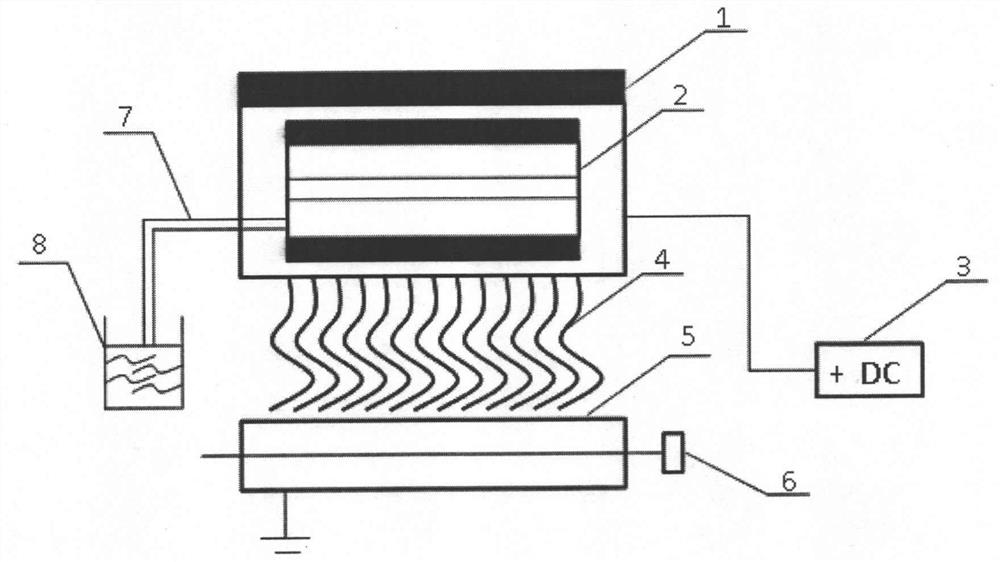

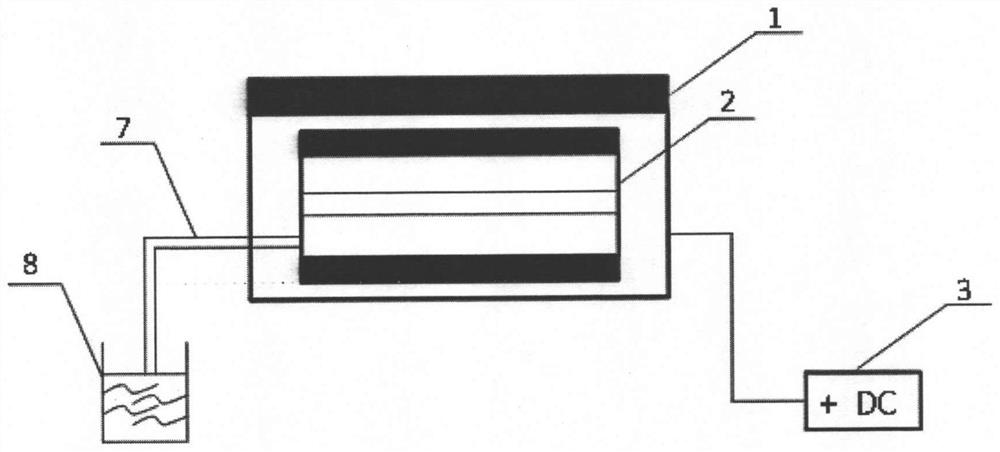

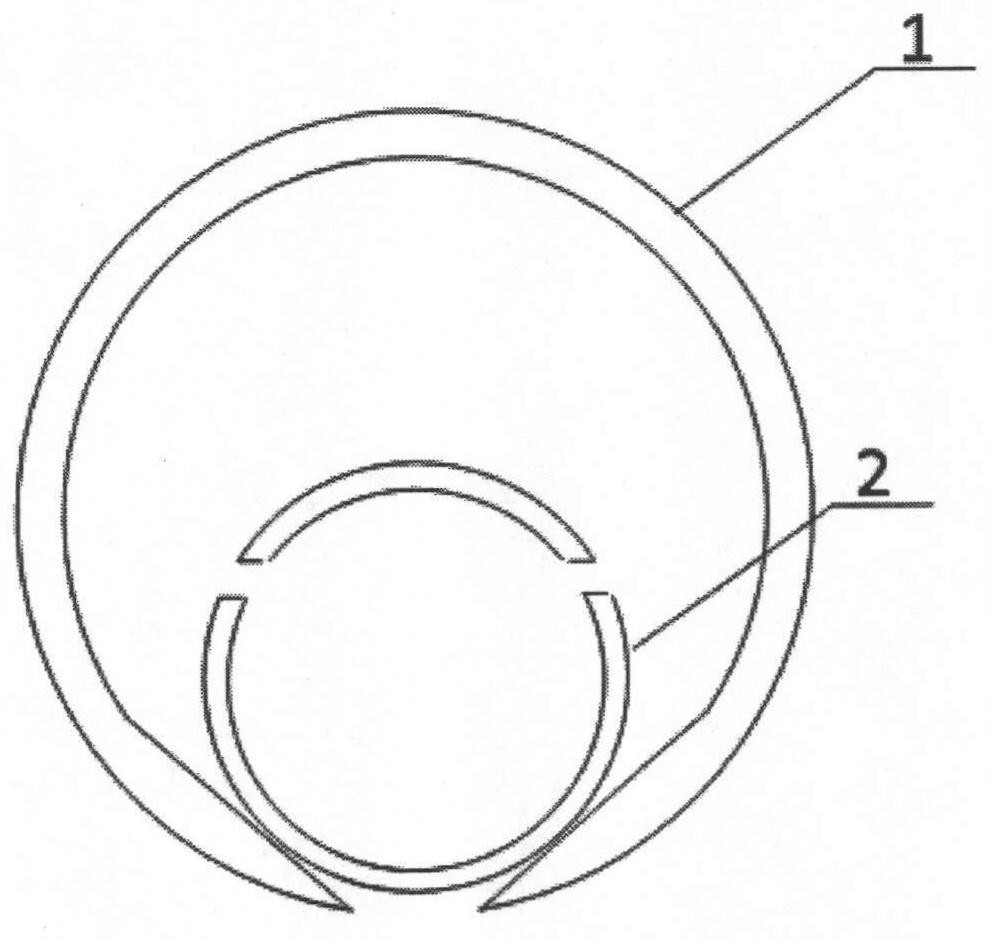

[0023] Such as Figure 1-3 As shown, it is a structural schematic diagram of the gravitational cylindrical electrospinning device provided in this embodiment, which includes a cylindrical nozzle 1, a cylindrical liquid supply device 2 with a gap is arranged in the cylindrical nozzle 1, and a cylindrical liquid supply device 2 is provided in the cylindrical nozzle 1. The device 2 is connected to the solution propeller 8 on the outside of the cylindrical spray head 1 through the hose 7, and the shell of the cylindrical spray head 1 is connected to the positive pole of the high-voltage generator 3; a metal drum 5 with a frequency conversion motor 6 is arranged under the cylindrical spray head 1, Its case is grounded. The distance between the metal cylinder 5 and the cylindrical nozzle 1 is 200mm.

[0024] Cylindrical nozzle 1 is a hollow cylinder with a wall thickness of 10-20mm, a length of 400-600mm, and a cross-sectional diameter of 200-400mm; the width of the nozzle below th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com