PHBV/PLA absorbable suture

A suture thread and fiber technology, applied in the direction of filament/thread forming, conjugated synthetic polymer artificial filament, single-component copolyester artificial filament, etc., can solve problems such as deficiencies, and achieve complementary material properties and mechanical properties The effect of high strength and slow degradation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1, PHBHHx monofilament fiber

[0053] PHBHHx (the weight-average molecular weight is 230000, the number-average molecular weight is 125000, the polydispersity coefficient is 1.8, the mass percentage composition of 3-hydroxycaproic acid is 12%) joins the extruder of laboratory model (Ruojiang Chemical Fiber Company, Beijing, China) Press, extrude at 130°C in a spinneret hole with an inner diameter of 1 mm, wind up at a speed of 100 cm / min and quench in ice water at 0°C to obtain non-crystalline primary spinning. The extrusion speed is 60cm / min. Isothermal crystallization in ice bath for 3h and post-stretching. Under tension-maintaining conditions, anneal at room temperature for one day. The stretching speed is 10 m / min, and the diameter of the stretched monofilament fiber is 60 μm to 500 μm.

[0054] The performance of the monofilament fiber prepared in this embodiment is tested below.

[0055] (1) The scanning electron micrographs of the monofilament diam...

Embodiment 2

[0065] Embodiment 2, PHBHHx / PLA monofilament fiber

[0066] 10wt% PHBHHx (the weight-average molecular weight is 230000, the number-average molecular weight is 125000, the polydispersity coefficient is 1.8, the mass percent content of 3-hydroxyhexanoic acid is 12%) and 90wt% PLA (the molecular weight is 120000, wherein L- The mass percent content of isomer is 48%) after melting, granulate, add extruder at 130°C, extrude in the spinneret hole of 1mm inner diameter, wind with 40~50cm / min speed and quench in 0°C water Cold, to obtain non-crystalline primary spinning. The extrusion speed is 60cm / min. Isothermal crystallization in ice bath for 5h and post-stretching. Under tension-maintaining conditions, anneal at room temperature for one day. The stretching speed is 12 m / min, and the fiber diameter after stretching is 50 μm to 300 μm.

[0067] The performance of the monofilament fiber prepared in this embodiment is tested below.

[0068] (1) The scanning electron micrographs ...

Embodiment 3

[0074] Embodiment 3, PHBV / PLA bundle fiber

[0075] Get 10~30wt% PHBV (molecular weight 500000, wherein the mass percent content of 3-hydroxyvaleric acid ester is 12%) and 70~90wt% PLA (molecular weight is 120000, wherein the mass percent content of L-optical isomer is 48%) mixed in a high-speed mixer, injected into a twin-rod extruder to melt, extruded through 24-hole or 72-hole spinneret holes, the extrusion speed is 1000m / min, and then drawn twice under the condition of 65°C After heat setting, the obtained fiber diameter is 12-16 μm.

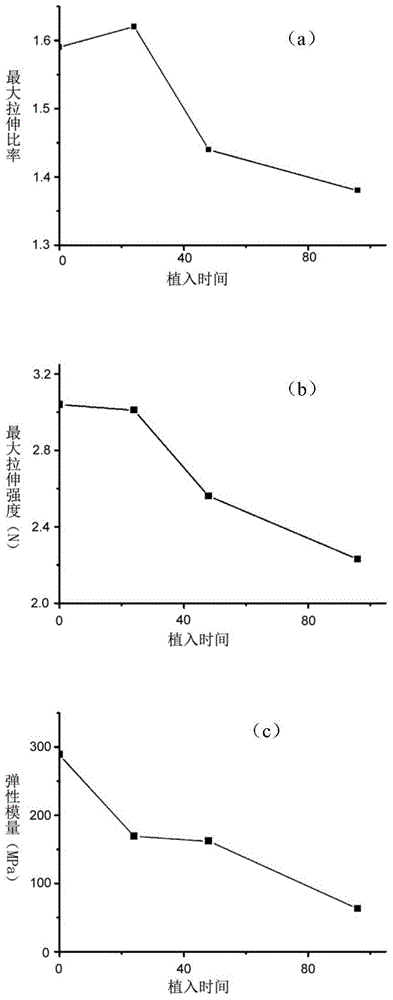

[0076] The properties of the bundled fibers prepared in this example are tested below.

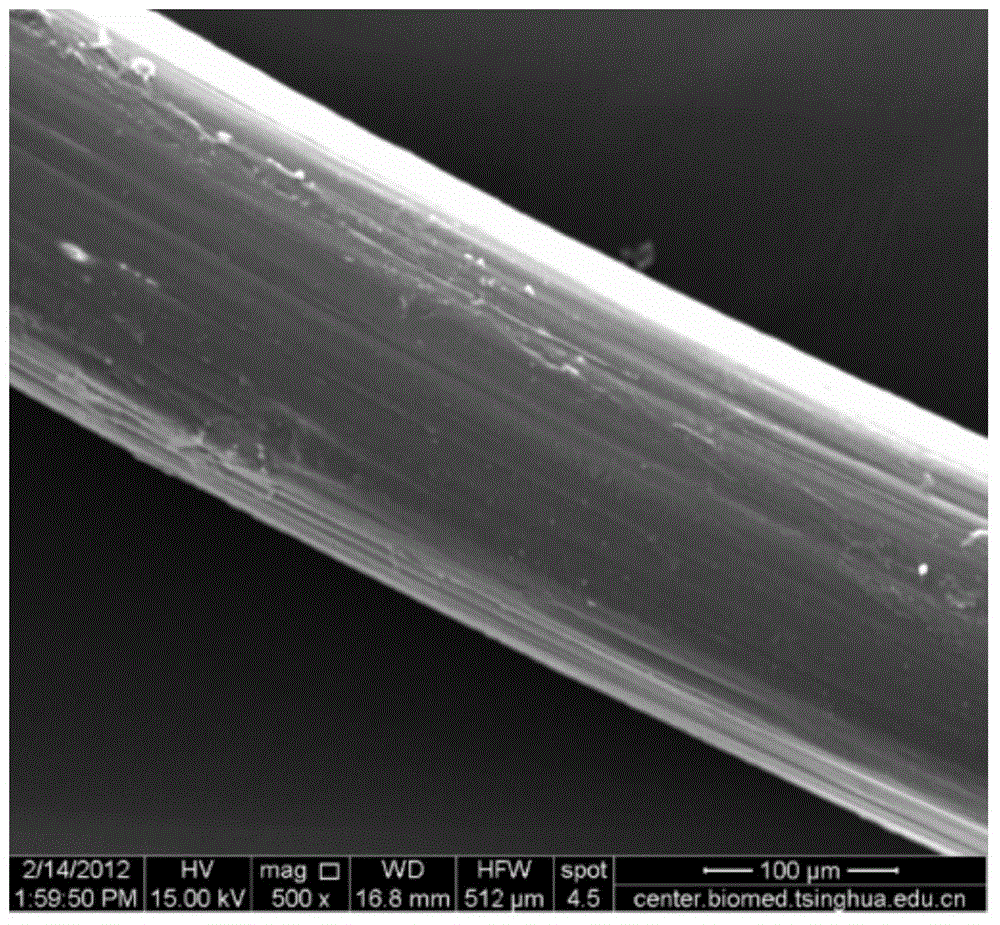

[0077] (1) The scanning electron micrographs of PHBV / PLA bundled fibers (2 / 8, m / m) with a single fiber diameter of 12 to 16 μm prepared in this example are as follows Figure 5 shown.

[0078] (2) The mechanical properties of the PHBV / PLA bundled fibers prepared in this example are shown in Table 3.

[0079] The mechanical properties of each fiber bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com